Bendix Commercial Vehicle Systems EC-60 ESP CONTROLLERS ADV User Manual

Page 27

27

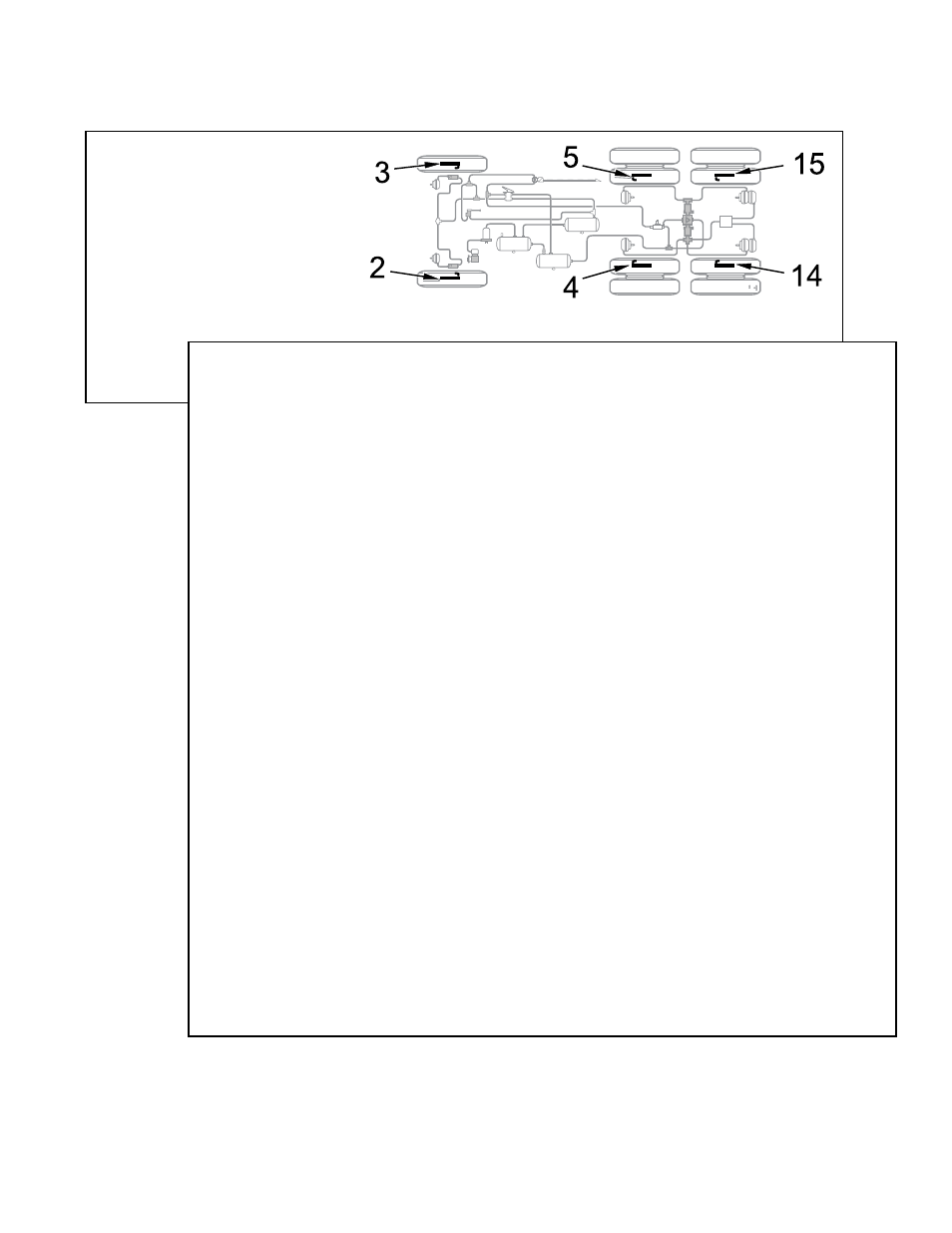

Troubleshooting Diagnostic Trouble Codes:

Wheel Speed Sensors

2

Left Steer Axle Sensor

3

Right Steer Axle Sensor

4

Left Drive Axle Sensor

5

Right Drive Axle Sensor

14

Left Additional Axle Sensor

15

Right Additional Axle Sensor

1st . Blink

Code

Location

2nd .

Blink

Code

Diagnostic Trouble

Code Description

Repair Information

1

Excessive Air Gap

Adjust sensor to contact exciter ring. Rotate wheel and verify a minimum

of 0.25 VAC sensor output at ~ 0.5 RPS. Verify condition of sensor head.

Verify mounting of exciter ring and condition of teeth. Verify proper bearing

end-play. Verify condition and retention of clamping sleeve. Verify sensor

lead routing and clamping.

2

Output Low at

Drive-off

Adjust sensor to contact exciter ring. Rotate wheel and verify a minimum

of 0.25 VAC sensor output at ~ 0.5 RPS. Verify condition of sensor head.

Verify mounting of exciter ring and condition of teeth. Verify proper bearing

end-play. Verify condition and retention of clamping sleeve. Verify sensor

lead routing and clamping.

3

Open or Shorted

Verify 1500 – 2500 ohms across sensor leads. Verify no continuity between

sensor leads and ground or voltage. Verify no continuity between sensor

leads and other sensors. Check for corroded/damaged wiring or connectors

between the ECU and the wheel speed sensor.

4

Loss of Sensor

Signal

Adjust sensor to contact exciter ring. Rotate wheel and verify a minimum

of 0.25 VAC sensor output at ~ 0.5 RPS. Verify condition of sensor head.

Verify mounting of exciter ring and condition of teeth. Verify proper bearing

end-play. Verify condition and retention of clamping sleeve. Verify sensor

lead routing and clamping. Check for corroded/damaged wiring or connectors

between the ECU and the wheel speed sensor.

5

Wheel End

Verify mounting of exciter ring and condition of teeth. Verify proper bearing

end-play. Verify condition and retention of clamping sleeve. Verify sensor

lead routing and clamping. Check mechanical function of brake. Check for

kinked or restricted air lines.

6

Erratic Sensor

Signal

Adjust sensor to contact exciter ring. Rotate wheel and verify a minimum

of 0.25 VAC sensor output at ~ 0.5 RPS. Verify condition of sensor head.

Verify mounting of exciter ring and condition of teeth. Verify proper bearing

end-play. Verify condition and retention of clamping sleeve. Verify sensor

lead routing and clamping. Check for corroded/damaged wiring or connectors

between the ECU and the wheel speed sensor.

7

Tire Size

Calibration

Verify correct tire size as desired. Verify proper tire inflation. Verify correct

number of exciter ring teeth.

10

Configuration

Error

ECU is configured for four sensors, but has detected the presence of

additional sensors. Verify sensor wiring and ECU configuration.