Rockwell Automation Isomag 4 Universal Guard Safety Switch User Manual

Isomag 4

Actuator

Switch

UNIVERSAL

GUARD

SAFETY

SWITCH

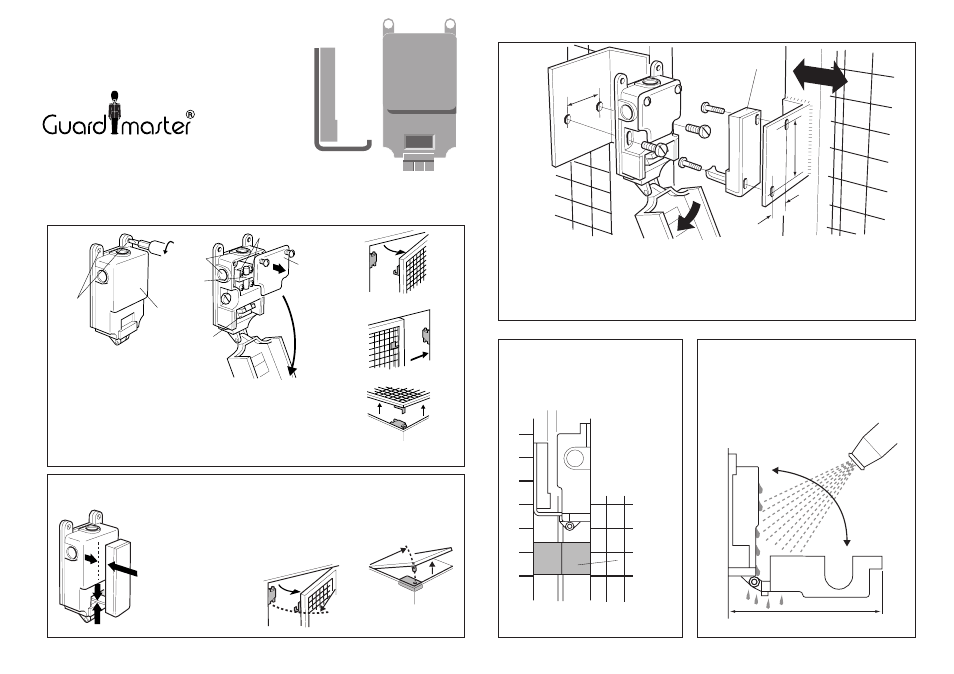

Follow steps 1 to 7 for correct installation.

INSTALLATION INSTRUCTIONS

Isomag 4

Security Key

Cover

Retaining

Screws

Cover

Coduit

Entries

Isomag

Insulating

Barrier

Operating

Cam

Safety Contacts

Internal

Contact

Cover

Aux Contacts

Hinged Guards

Sliding Guards

Lift-Off Guards

The cover of the Isomag switch

hinges down to allow access to

the fixing holes. Unscrew the 2

cover retaining screws using the security key supplied and

swing down the cover. The internal plastic cover protects the

electrical contacts and the ISOMAG Insulating Barrier.

The ISOMAG 4 can be fitted in any position on hinged,

sliding or lift-off guards.

The switch will accommodate inaccuracies in the guard or door but it should not

be used as a guide. When correctly installed the bottom of the actuator tongue

should clear the entry hole by 1mm. When the guard is closed there should

be a gap of 3 to 6mm between the actuator and switch faces.

On hinged guards the

minimum radius from the

hinge point to the actuator

tongue centre

should be as

shown.

Min radius

370mm

Min radius

170mm

3 to

6mm

1mm

40

Switch

Actuator

M5

60.5

19.5

Hinge down the cover to gain access to the

mounting holes. Mount the switch on the

stationary section of the guard using 2 x

M5 fixings. Use mounting brackets if

necessary.

Mount the actuator on the moving guard

section with the actuator tongue centrally

opposite the switch entry hole. Use the

two security screws provided. The

elongated holes allow adjustment before

fully tightening the screws.

The guard door

must be fitted

with a stop to

ensure a gap of

3 to 6mm. The

actuator MUST

NOT be allowed

to strike the

switch when the

guard door is

closed.

3mm MIN

6mm MAX

STOP

150mm

The switch cover can be hinged

down for high pressure hosing.

A gap of 150mm is required to allow

the switch lid to hinge down.

5

3

4

2

1