Adjust the gap – Rockwell Automation 1442 Eddy Current Probe System User Manual

Page 30

30

Rockwell Automation Publication ICM-UM004C-EN-E - February 2014

Chapter 1

Installation

Adjust the Gap

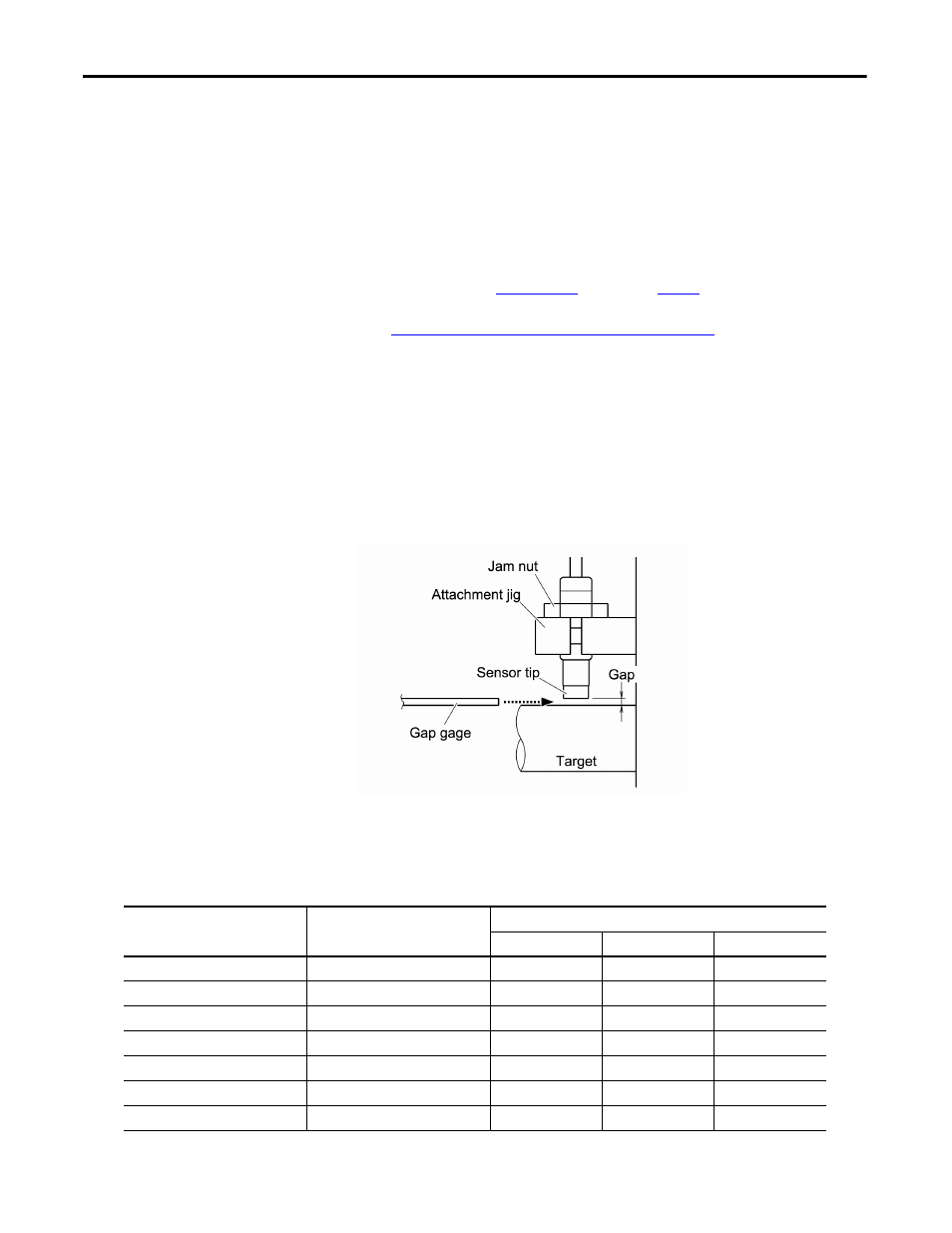

Adjust the gap by using the following procedures.

1.

Refer to Standard Static Characteristics on page 41

, and prepare a gap gage

matching the gap to produce the desired characteristics.

Consider the following items for the gap:

• Set the gap so that even when the target is at the nearest point to the

sensor, the target does not come into direct contact with the sensor.

• Set the gap so that it does not go beyond the linear range of the

connection monitor.

2. Being careful not to scratch the sensor top and target surface, insert the gap

gage between the sensor top and target.

3. Adjust the sensor to a position where the gap gage just moves freely, and

affix in place with the jam nut.

4. Tighten the jam nut with the following torque.

TIP

After completing all wiring connections, you can perform gap adjustment

by using a tester.

Make sure to fully understand the content described in this chapter and

complete all connection work, then perform the gap adjustment by using

the

procedures on

page 35

Table 2 - Torque Requirements

Sensor

Example

Tightening Torque

N•m

kgf-cm

lb•in

1442-PS-05xxM (5 mm metric)

1442-PS-0503M0010N

4

41

35.4

1442-PS-05xxE (5 mm English)

1442-PS-0512E0010N

1.4

15

12.4

1442-PS-08xxM (8 mm metric)

1442-PS-0803M0010N

8.5

87

75.2

1442-PS-08xxE (8 mm English)

1442-PS-0812E0010N

6.8

69

60.2

1442-PS-11xxM (11 mm metric)

1442-PS-1104M0510N

26.1

266

231

1442-PS-11xxE (11 mm English)

1442-PS-1116E0510N

18.6

190

164

1442-PS-18xxM (18 mm metric)

1442-PS-1805M0510A

58.8

600

520