Install cables – Rockwell Automation 2090-CPxxx Standard Power Cables with SpeedTec DIN Connector Type 940 Installation Instruct User Manual

Page 4

4 Standard Power Cables with SpeedTec DIN Connector Type 940

Publication 2090-IN023A-EN-P - September 2010

Install Cables

Follow these steps when installing a cable.

1.

Identify the recommended installation areas and the correct offset from features before

beginning any cable bend. Features include these areas on the cable:

•

Connectors

•

Transitions from exposed wire to insulation (for example, flying leads)

•

Exposed cable ground shields

The offset from these features should be greater than or equal to (>1x) the cable

diameter.

2.

Keep cable bends within the bend radius specified on

3.

When installing a cable observe these restrictions:

•

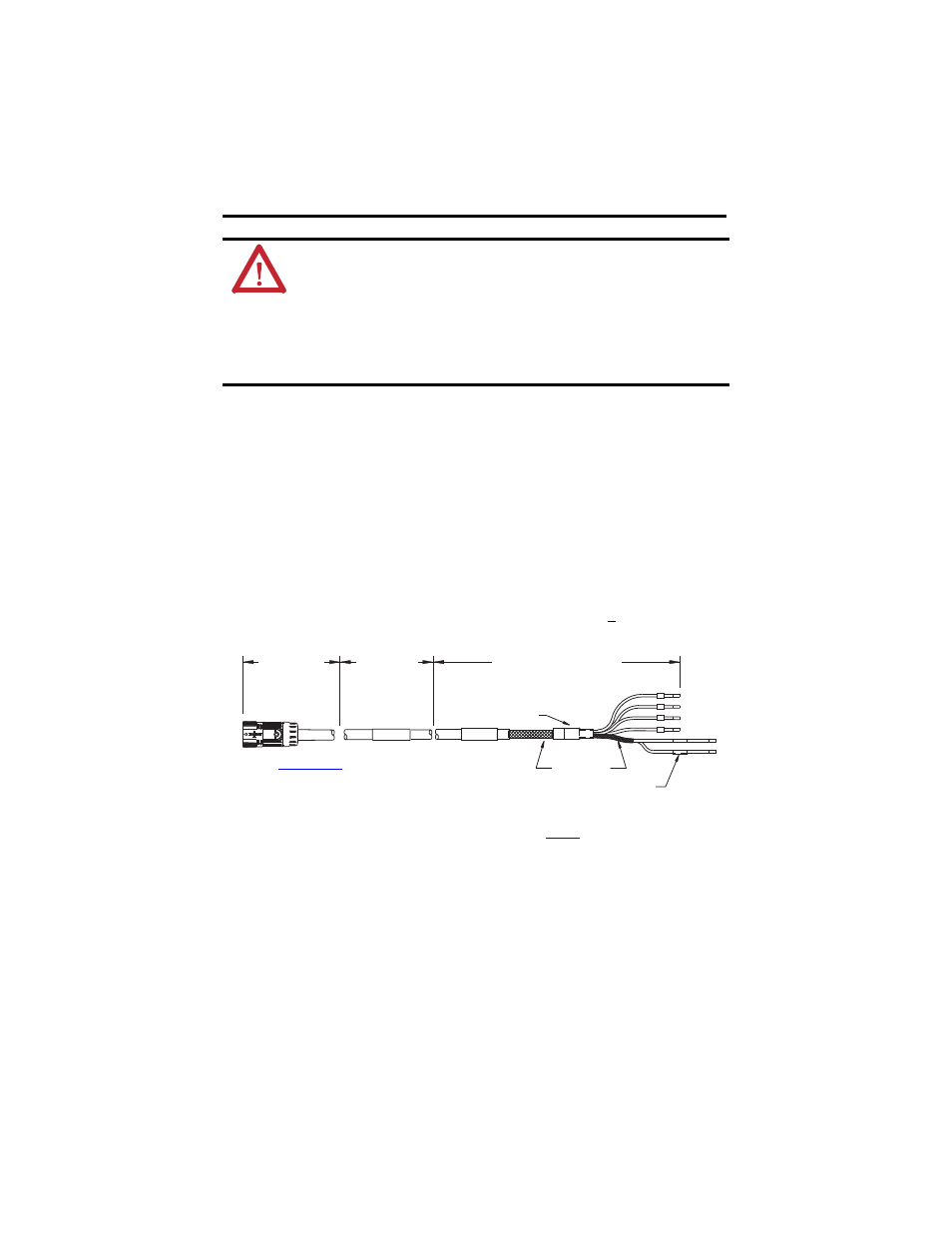

The bend zone is the area in which the cable can bent to its specified bend radius.

•

The installation areas require strain relief to minimize cable flexing, and to reduce

the possibility of cable fatigue where the cable connects to other components.

4.

Identify each connection on a cable by attaching a label around the outer insulation of

each wire adjacent to the drive connection.

ATTENTION: The examples in this publication show all the available

connections, some of which may not be appropriate for your specific

installation. Refer to your drive installation or user manual for recommended

wire trim lengths, and wiring examples appropriate to your drive and motor

application.

Do not connect unused wires. Unused wires may be trimmed and finished as

necessary to prevent accidental contact with other wires or wire shields, or with

a ground connection.

Limited

Bend Zone

Installation

Area

Installation Area

Label

(6 Places)

Exposed

Shields

Refer to

for recommended

Installation Area and Bend Zone values.

Shrink Wrap