Wiring requirements – Rockwell Automation 2198-CAPMOD-1300 Kinetix 5500 Capacitor Module Installation Instructions User Manual

Page 6

6 Kinetix 5500 Capacitor Module

Publication 2198-IN004A-EN-P - October 2012

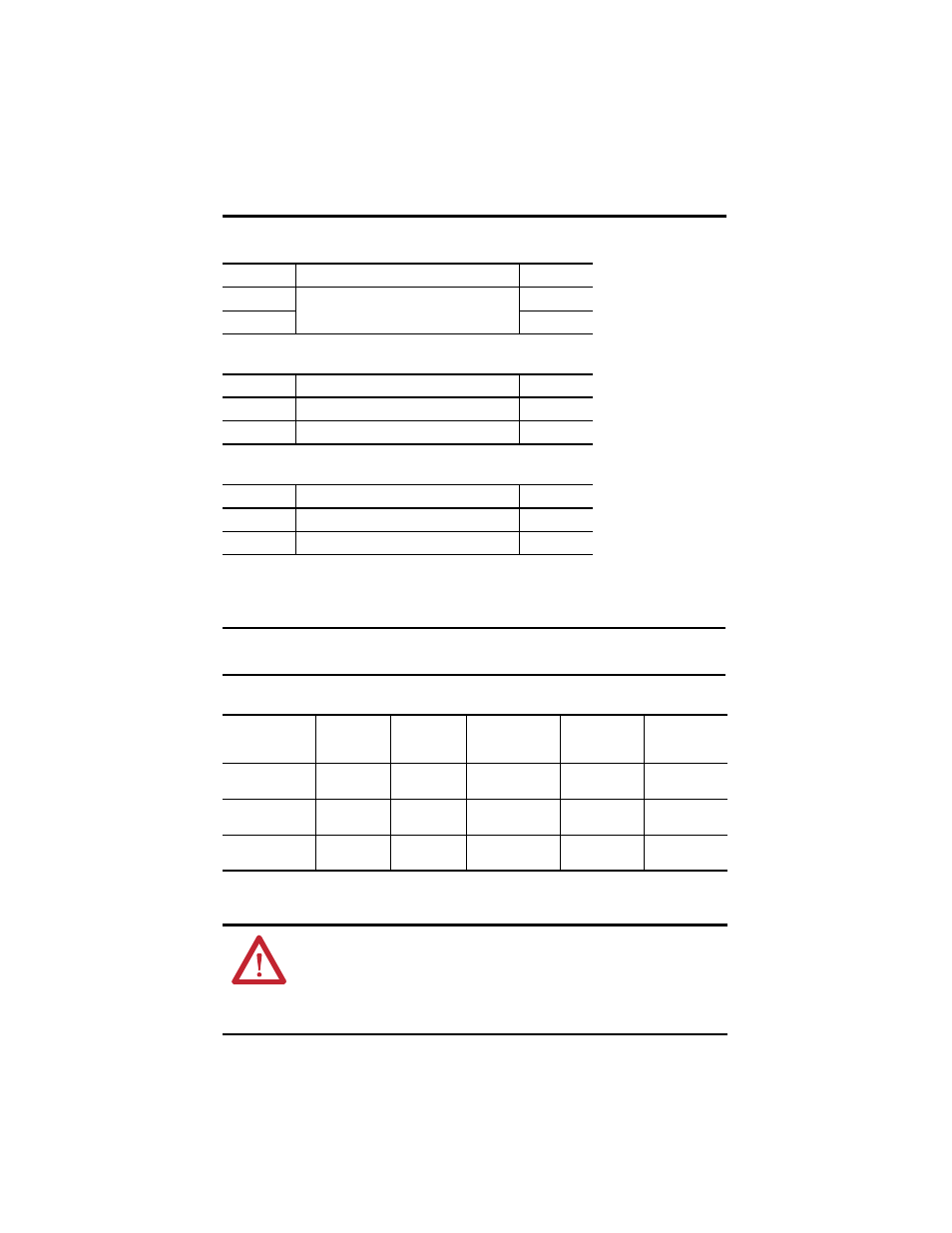

Table 2 - DC Bus (DC) Connector Pinout

Table 3 - Control Input Power (CP) Connector Pinout

Table 4 - Module Status (MS) Connector Pinout

Wiring Requirements

Table 5 - Capacitor Module Wiring Requirements

DC Pin

Description

Signal

1

DC bus connections

DC-

2

DC+

CP Pin

Description

Signal

1

24V power supply, customer-supplied

24V+

2

24V common

24V-

MS Pin

Description

Signal

1

Module status relay output +

RELAY+

2

Module status relay output -

RELAY-

IMPORTANT

The National Electrical Code and local electrical codes take precedence over the values and

methods provided.

Connector

Description

Pin

Signal

Recommended

Wire Size

mm

2

(AWG)

Strip Length

mm (in.)

Torque Value

N•m (lb•in)

Module Status

indicator

MS-1

MS-2

RELAY+

RELAY-

0.14…1.5

(28…16)

7.0 (0.28)

0.22…0.25

(1.9…2.2)

PELV/SELV

24V power

CP-1

CP-2

24V+

24V-

N/A

N/A

DC bus power

DC-1

DC-2

DC-

DC+

N/A

(1)

(1)

24V control power and DC bus connections are always made from drive-to-drive over the shared-bus connection system. These terminals do not

receive discrete wires.

N/A

ATTENTION: To avoid personal injury and/or equipment damage, observe the following:

• Make sure installation complies with specifications regarding wire types, conductor sizes,

branch circuit protection, and disconnect devices. The National Electrical Code (NEC) and local

codes outline provisions for safely installing electrical equipment.

• Use power connectors for connection purposes only. Do not use them to turn the unit on and off.

• Ground shielded power cables to prevent potentially high voltages on the shield.