Important, User interface – Rockwell Automation 42GR Series 9000 LaserSight User Manual

Page 2

2

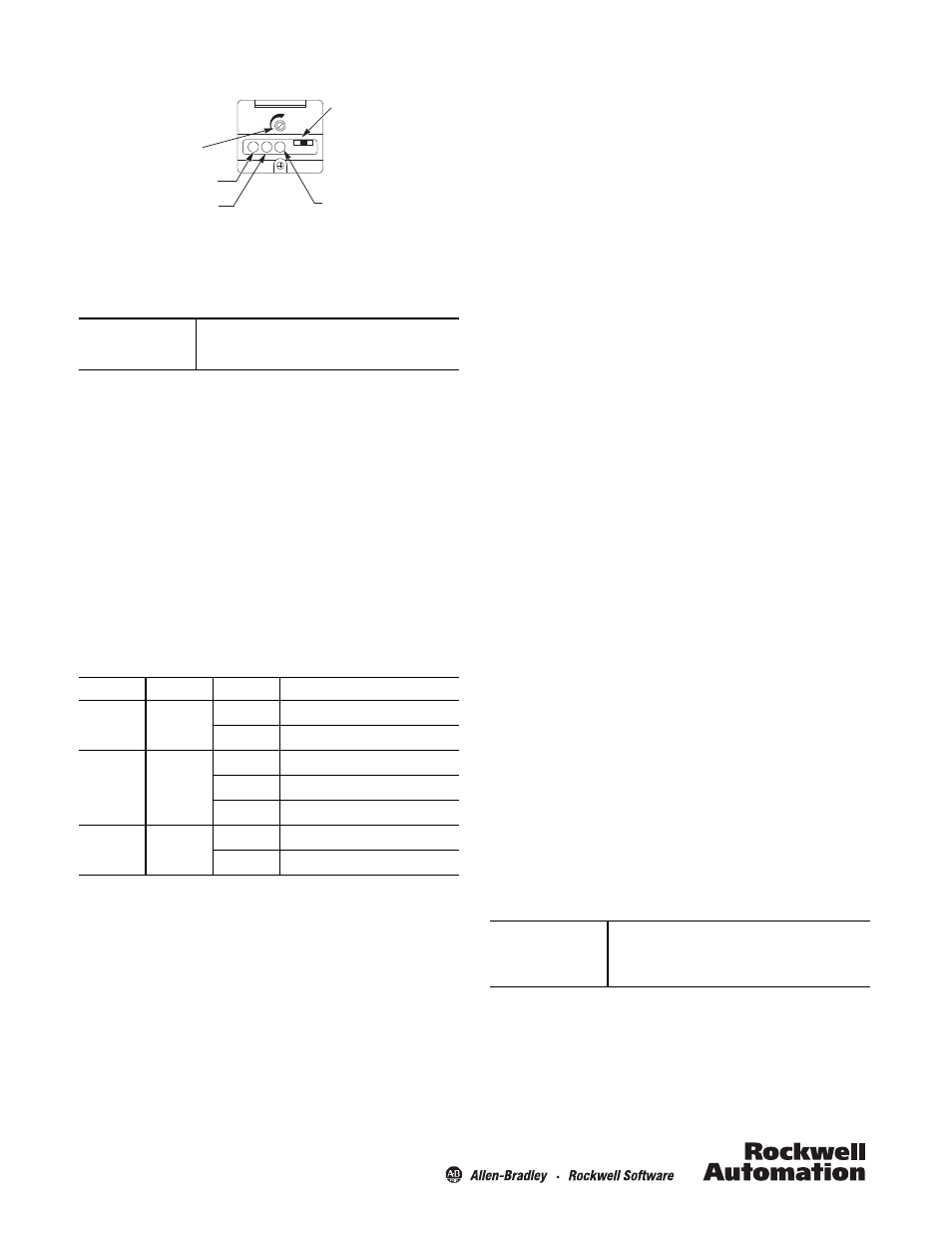

User Interface

Using a screwdriver, open the top cover of the sensor to access

the user interface panel. This panel contains a single-turn

sensitivity adjustment knob, a two-position mode selector switch,

along with three LED status indicators.

Using a screwdriver, the sensitivity can be increased (clockwise) or

decreased (counterclockwise) to meet the application

requirements. The factory default setting for all versions is

maximum sensitivity.

The LaserSight photoelectric sensor also contains a two-position

selector switch. This switch is used to select either light or dark

operate mode of the sensor. In the light operate mode, the sensor

output will turn ON when the light is being reflected back to the

sensor (reflector for retroreflective, source for transmitted beam

or target for diffuse). In dark operate mode, the sensor output will

turn OFF when no light is being reflected back to it.

After initial sensor configuration, ensure that the

user interface cover is closed tightly to maintain

specified environmental rating!

Status Indicators

Sensor Alignment

The red LED indicator is an alignment aid which indicates that a

margin of 2X has been reached. This means that the sensor is

receiving at least 2 times the signal strength back from the target

needed to trigger an output signal. In general, it is desirable to

have a higher margin to help overcome any deteriorating

environmental conditions, e.g. dust buildup on the sensor's lens.

When aligning the sensor, the best performance can be obtained

if this margin indicator is illuminated with the target in place.

Label

Color

State

Status

Output

Green

OFF

Output de-energized, SCP active

ON

Output energized

Margin

Red

OFF

Margin < 2

ON

Margin > 2

Flashing

Output SCP active

Power

Yellow

OFF

Sensor not powered

ON

Sensor powered

Yellow Power

On Indicator

Green Output

Energized Indicator

Red Margin/

SCP Indicator

Light/Dark

Operate Switch

Sensitivity

Adjustment

IMPORTANT

Damage to the single-turn sensitivity

adjustment knob may occur if turned

beyond min./max. stop points.

Transmitted Beam Models

1. Visually align the emitter and receiver units until the green

output LED turns ON (with light-operate mode) or turns OFF

(with dark-operate mode).

2. To ensure that the beam is centered, it is recommended to

sweep the emitter or receiver in the horizontal and vertical

plane and determine at what position the output indicator

turns ON and then turns OFF. Set the sensor midway between

both positions. The red margin LED should also be ON when

the beam is not broken.

Polarized Retroreflective Models

1. Visually align the sensor on the reflector until the green

output LED turns ON (with light-operate mode) or turns OFF

(with dark-operate mode).

2. To ensure that the beam is centered, it is recommended to

sweep the sensor in the horizontal and vertical plane and

determine at what position the output indicator turns ON and

then turns OFF. Set the sensor midway between both

positions.

3. Break the beam with the object to be detected and check if the

output indicator turns ON (dark-operate mode). If this does

not occur, turn down the sensitivity adjustment until it does.

Restore the light beam by removing the object and check if the

output indicator turns OFF again and the red margin LED comes

ON. If this does not occur, increase the size of the reflector or

decrease the distance between the reflector and the reflector.

Diffuse Models

1. Visually align the sensor on the object until the green output

LED turns ON (with light-operate mode) or turns OFF (with dark-

operate mode).

2. To ensure that the beam is centered, it is recommended to

sweep the sensor in the horizontal and vertical plane and

determine at what position the output indicator turns ON and

then turns OFF. Set the sensor midway between both positions.

3. Remove the object in front of the sensor and eliminate any

background reflection by turning down the sensitivity

adjustment, if such background exists. Replace the object and

verify that the output LED turns ON and the margin LED is ON.

If the sensor continues to detect background reflections by

turning down the sensitivity, it is recommended to eliminate

these reflections by painting with a nonreflective color or to

replace the sensor with a background suppression, sharp cutoff

diffuse or retroreflective sensing mode sensor.

Mounting the Sensor

Securely mount the sensor on a firm, stable surface or support. A

mounting which is subject to excessive vibration or shifting may

cause intermittent operation. Adaptors and mounting brackets

are available for a flexible installation. The sensor is supplied with

the hardware kit 129-130 which contains a plastic mounting nut,

lock washer, 2 M5 x 0.8 x 53 screws and nuts.

Once securely mounted, the sensor may be wired as indicated in

the wiring diagrams.

IMPORTANT

Securely close and tighten the screw on the

user interface cover. Failure to check for a

properly sealed user interface cover may

result in a malfunction or property damage.