Rockwell Automation 2090-CSBM1DF-10AF Single Motor Cables with Circular DIN Connector Type 740 Install Instructions User Manual

Page 2

2 Single Motor Cables with Circular DIN Connector Type 740

Rockwell Automation Publication 2090-IN049A-EN-P - October 2013

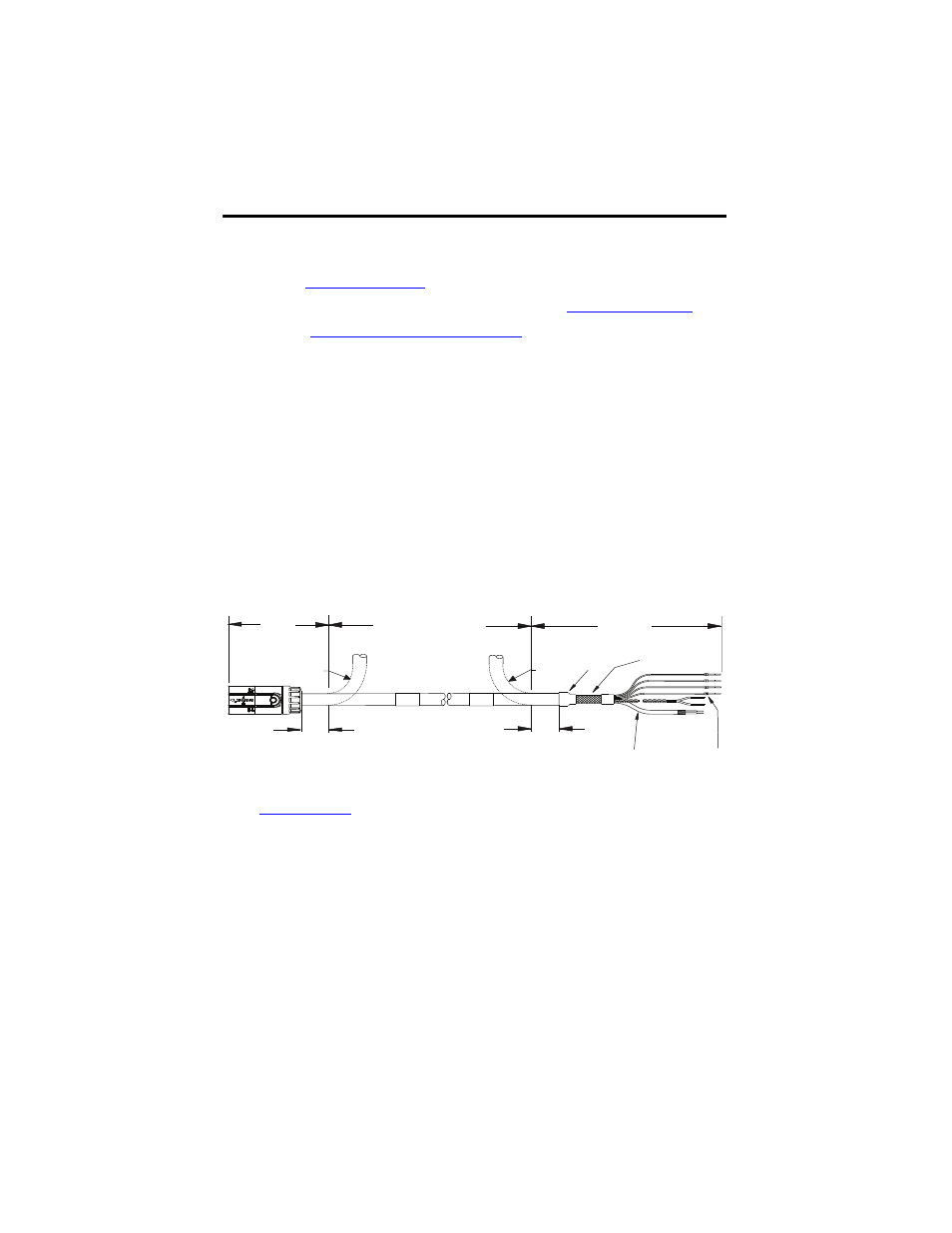

Follow these guidelines when installing a single motor cable:

•

Do not bend the cable within 76.2 mm (3.0 in.) of the connector or the flying-lead end.

See the

Installation Guidelines

illustration.

•

Do not exceed the bend radius limitation specified in the

.

•

Refer to

Cable Pinouts and Schematics on page 3

to identify each wire and its respective

drive connection.

•

Remove and discard the protective sleeve from the data signal wires shortly before you

install these wires on the feedback connector kit.

•

Connect unused brake conductors to the drive to prevent accidental contact.

For continuous-flex cables, follow these additional installation requirements:

•

The continuous-flex zone is the area where the cable can repeatedly flex up to its

specified bend radius.

•

Installation areas require rigid mounting to prevent the cable from flexing where it

connects to other components.

Installation Guidelines

Continuous-flex Zone

Installation

Area

Installation

Area

Signal

Labels

Exposed Shield

Shrink

Wrap

for recommended

continuous-flex zone radius values.

Insulated and

Shielded

Twisted Pair

2090-CSBM1DF-10AF

xx cable shown.

76.2 mm

(3.0 in.)

76.2 mm

(3.0 in.)

Bend

Radius

Bend Radius