E - doc – Rockwell Automation 2030-RLS_ _D Dual Remote Lockout Station User Manual

Page 2

IMPORTANT: The maximum total cable length between all of the RLSs and the Control Module in the ElectroGuard® Power Panel shown in

Table 2 must not be exceeded. This may affect the reliable operation of the ElectroGuard®. Consider using an optional Expansion Module if cable

lengths greater than those shown are needed (see Installation and Wiring of the Expansion Module in Chapter 2 of the ElectroGuard® User Manual

Revision 2030-UM003A-EN-P or later).

1

1013449

42052-125

OF

N/A

N/A

N/A

REVISION

AUTHORIZATION

DR.

CHKD.

APPD.

DATE

DATE

DATE

E - DOC

LOCATION: MILWAUKEE, WISCONSIN U.S.A.

B-vertical.ai

DWG.

SIZE

SHEET

B

1

2

3

4

5

6

7

8

A

B

C

D

E

F

G

H

REFERENCE

DIMENSIONS APPLY BEFORE

SURFACE TREATMENT

(DIMENSIONS IN INCHES)

TOLERANCES UNLESS

OTHERWISE SPECIFIED

.XX:

.XXX:

ANGLES:

42052

---------------

----------

----------

----------

---------------

---------------

2

4

DUAL REMOTE LOCKOUT STATION

INSTALLATION INSTRUCTION SHEET

The cable lengths in Table 2 represent the total wire impedance allowed to help ensure proper operation of the safety monitoring relays

used in the isolation system. See Appendix C of the ElectroGuard® User Manual regarding length calculation, conductor sizing and

installation scenarios. Note that each Dual RLS is connected to two separate ElectroGuard® units, and a cable length calculation must

be done for both systems separately. When doing individual calculations, use only the length of the cable connected directly to that unit.

Wiring the Dual Remote Lockout Station

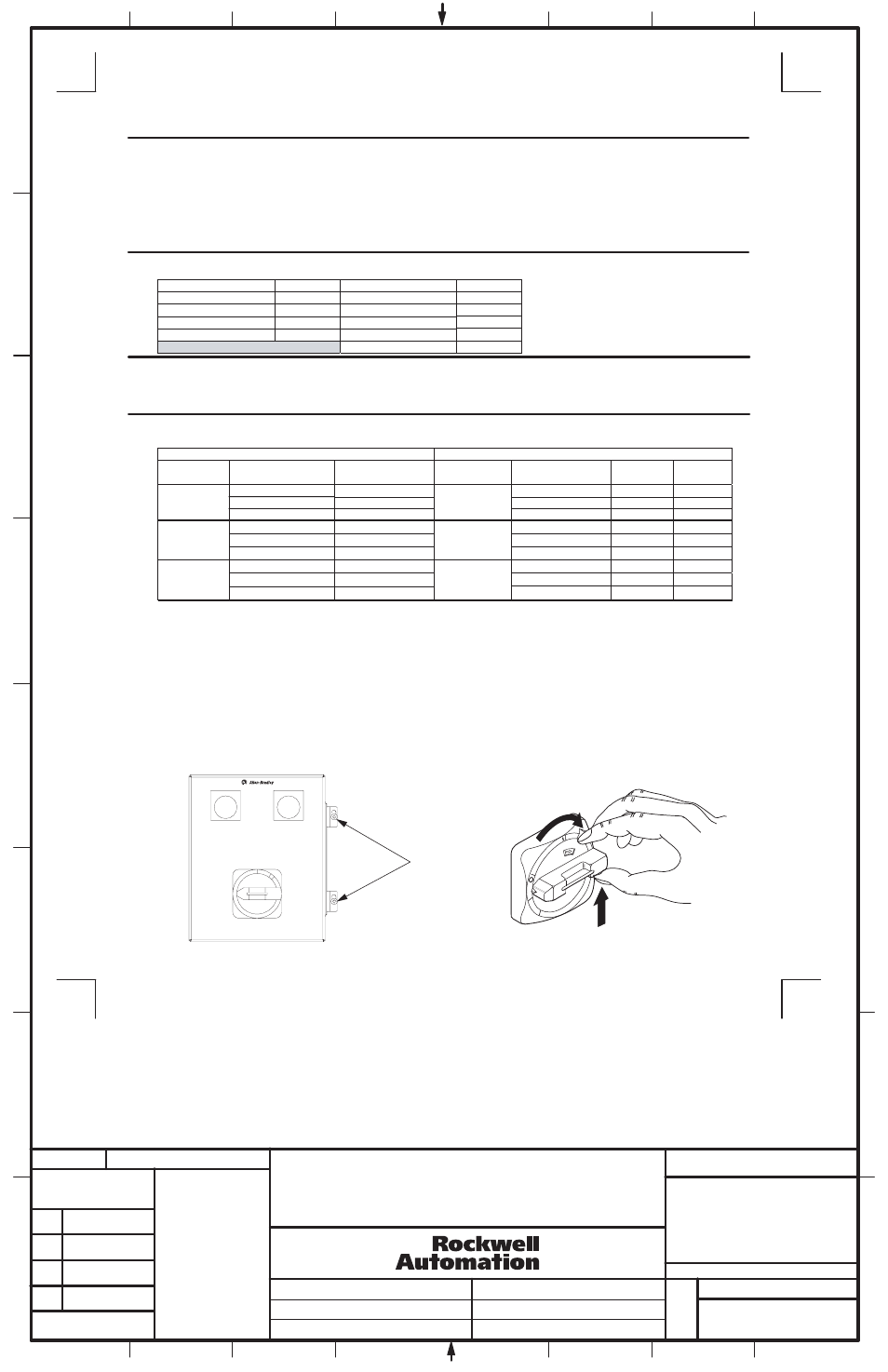

1. Open the RLS enclosure by loosening the two cover clamp screws (See Figure 2).

With the opearting handle held in the OFF position, squeeze the interlock lever and the operation handle held as in Figure 3. Lift the

cover away from the base.

Figure 2

Loosening the Dual RLS Cover Clamp

Figure 3

Operating Interlock Lever to Open Dual RLS

Enclosure

Table 1

Suggested Color Scheme for Remote Lockout Station Cable

Remote Lockout Station Cable Specifications

RLS Terminal Block No.

Wire Color

RLS Terminal Block No.

Wire Color

1 Black

6

Yellow

2 Red

7

Brown

3 Blue

8

Violet

4 Orange

9

Gray

GND

Green

Table 2

Maximum Allowable Cable Lengths

In North America

Outside of North America

Wire

Gauge

Control Module

Connector

Maximum Total

Cable Length (ft.)

Wire

Gauge (mm

2

)

Maximum Total

Cable Length (m)

RLS1,

RLS1, RLS2, RLS3, RLS4

RLS1, RLS2, RLS3, RLS4

RLS1, RLS2, RLS3, RLS4

RLS2, RLS3

19,500

19,500

19,500

5,900

23A-85A

110A-1200A

X

---

---

---

---

---

---

X

X

X

X

X

---

X

5,900

14 AWG

RLS4, RLS5, RLS6

2.1

5,900

RLS1, RLS2, RLS3

12,250

12,250

12,250

3,735

3,735

16 AWG

RLS4, RLS5, RLS6

1.3

3,735

RLS1, RLS2, RLS3

7,650

7,650

7,650

2,330

2,330

18 AWG

RLS4, RLS5, RLS6

0.8

2,330

N

O

F

O

F

Cover

Clamp

Screws

SYSTEM ISOLATED

SYSTEM ISOLATED

(2)

THIS DRAWING IS THE PROPERTY OF

ROCKWELL AUTOMATION, INC.

OR ITS SUBSIDIARIES AND MAY NOT BE COPIED,

USED OR DISCLOSED FOR ANY PURPOSE

EXCEPT AS AUTHORIZED IN WRITING BY

ROCKWELL AUTOMATION, INC.

IMPORTANT:

·

Cable must have copper conductors only

.

·

Cable with 600V insulation is required.

·

Oil resistant cable is recommended.

·

Individual conductors within the cable should be color-coded or otherwise clear

ly marked (see Table 1).

·

Cable must have a shield with a drain wire Similar to: ALPHA wire X

TRA-GUARD® 2:

- Part No. 25450/9 for #14 AWG, 0.64" O.D.

- Part No. 25440/9 for #16 AWG, 0.61" O.D.

- Part No. 25430/9 for #18 AWG, 0.55" O.D.

---

X

---

X