3 field calibration – Rockwell Automation 61C615 RTD Termination Panel User Manual

Page 12

3Ć2

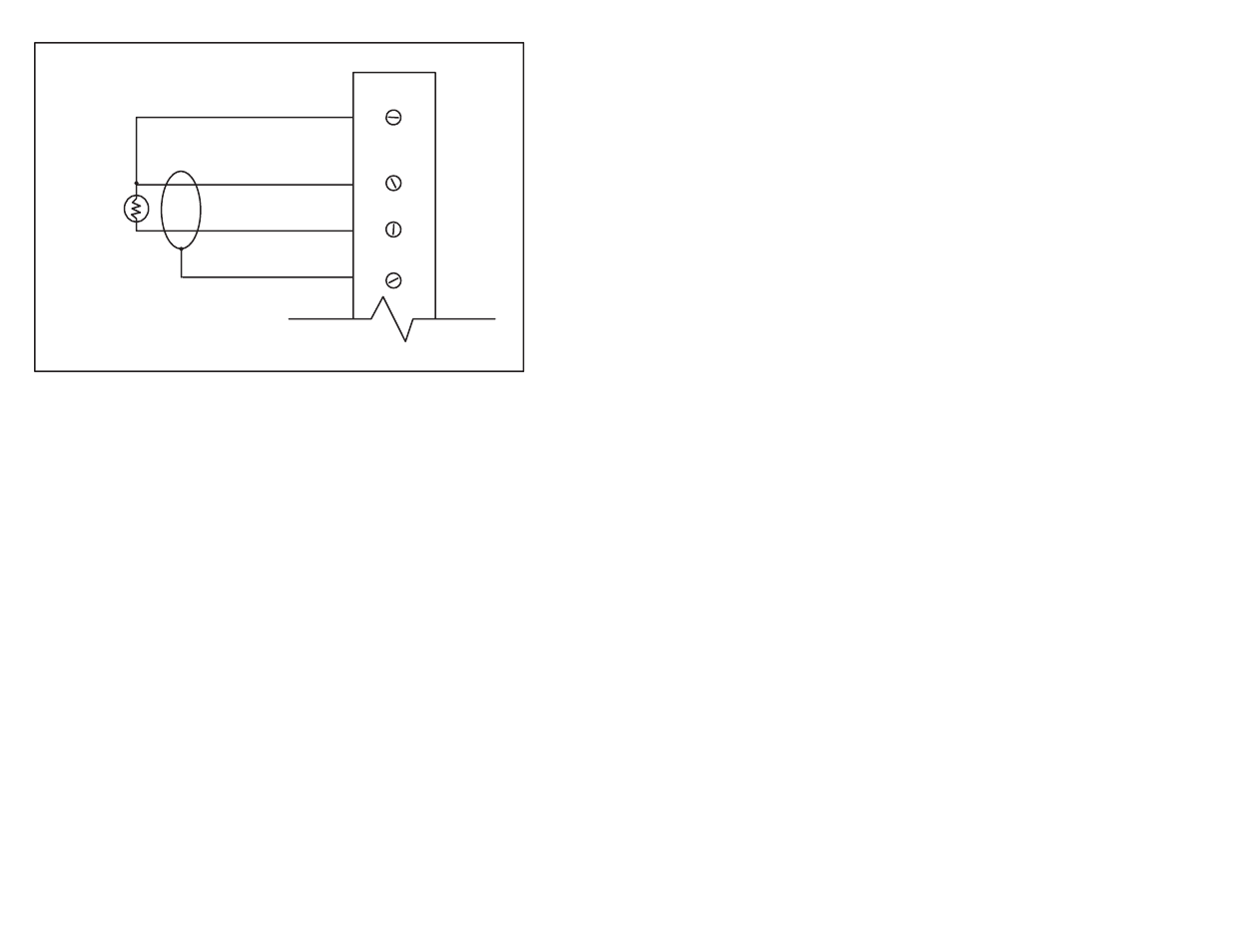

3 WIRE

100 OHM

RTD

4

3

2

1

SENSE (LOW0

LOW R

HIGH R (GND)

SHIELD

Figure 3.1Ć Typical Field Signal Connections

Step 6.

Connect the 50Ćpin flat cables to their corresponding

connector on the analog input module (61C613). Attach

the cables by aligning the triangle marks on the cable end

and the board socket. Input channels 0Ć7 (TB1) use the

middle connector on the input module. Input channels

8Ć15 (TB2) use the bottom connector. If the rack contains

more than one analog input module, make certain that the

connectors are the proper ones for this module.

Step 7.

Turn on power to the system.

Step 8.

Verify the installation. Refer to the instruction manual for

the 16 Channel Analog Input Module (JĆ3613Ć1).

3.3

Field Calibration

The termination panel is adjusted for European curve RTDs (alpha

temperature coefficient of 0.00385 ohms/ohm/degree C) and

includes an allowance for 0.1 ohm lead resistance. For lead

resistance greater than 0.1 ohm, the following procedure can be

used to calibrate the input for maximum accuracy:

1. The offset adjustment should not normally need further field

adjustment. If it becomes necessary, substitute a precision 100

ohm resistor in place of the RTD and adjust the offset

potentiometer for an output of zero volts. The offset

potentiometers are located at the back of the panel. Each

channel has a separate offset adjustment labeled OS".

2. Adjust the gain potentiometer so that total bridge voltage is

256.3mV across the 100 ohm resistor. The gain potentiometers

are located at the back of the panel. Each channel has a

separate gain adjustment labeled GN".