Installation, Inspection, Location – Rockwell Automation 1329R Std. Industrial AC Induction Motors User Manual

Page 6: Inspection location

6

Standard Industrial AC Induction Motors

Installation

Inspection

After the motor is unpacked, examine the nameplate data to see that it

agrees with the power circuit to which it is to be connected. The

motor will operate with frequency not more than 5% and voltage not

more than 10% above or below the nameplate data, or combined

variation of voltage and frequency of not more than 10% above or be

low nameplate data. Efficiency, power factor and current may vary

from nameplate data. Performance within these voltage and

frequency variations will not necessarily be in accordance with the

standards established for operation at rated voltage and frequency.

Location

The motor should be installed in a location compatible with the motor

enclosure and specific ambient.

To allow adequate air flow, the following clearances must be

maintained between the motor and any obstruction:

TEFC (IC0141) Enclosures

Fan Cover Air Intake

180-210T Frame

25.4 mm (1.00 in.)

250-449T Frame

101.6 mm (4.00 in.)

IEC 112 - 132

25.0 mm (0.98 in.)

IEC 160 - 280

100.0 mm (3.94)

Exhaust

Envelope equal to the “P” dimension on the motor dimension sheet

Protected Enclosures

Bracket Intake

Same as TEFC

Frame Exhaust

Exhaust out the sides-envelope a minimum of the “P” dimension plus

50.0 mm (1.97 in.). Exhaust out the end-same as intake.

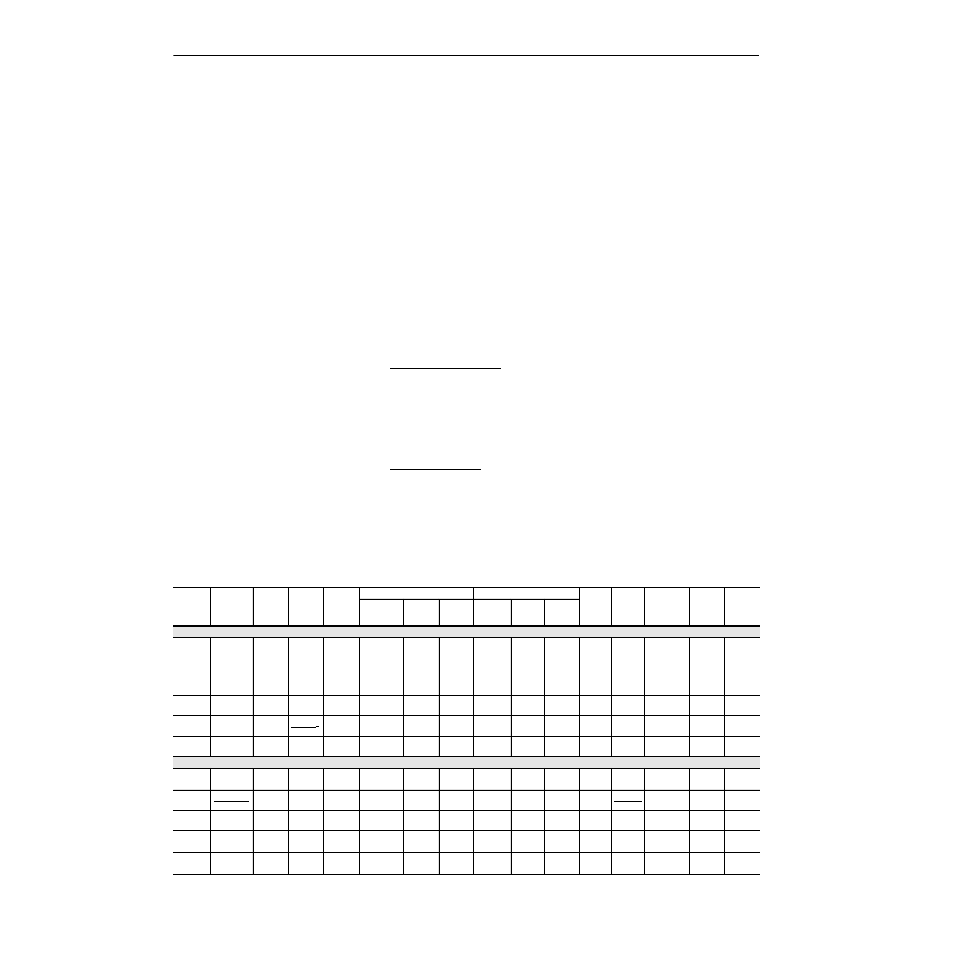

Table B

General Effect of Voltage & Frequency Variation on Induction-motor Characteristics

NOTE: This table shows goneral effects, which will vary somewhat for specific ratings.

Variation

Starting &

Maximum

Running

Torque

Sync

Speed

Slip %

Full Load

Speed

Efficiency

Power Factor/COS

Full

Load

Current

Starting

Current

Temperature

Rise

(full load)

Maximum

Overload

Capacity

Magnetic

Noise

(no-load in

particular)

Full-Load

3/4 Load

1/2 Load

Full Load

3/4 Load

1/2 Load

Voltage Variation:

120%

voltage

Increase

44%

No

change

Decrease

30%

Increase

1.5%

6-0%

Decrease

(1-75 HP)

0-3%

Increase

(100-200 HP)

Decrease

1/2-2

points

Decrease

7-20

points

Decrease

5-15 points

Decrease

10-30

points

Decrease

15-40

points

Increase

12%

Increase

20%

Increase 5-6

degrees C.

(1-75 HP)

Decrease 3-4

degrees C.

(100-200 HP)

Increase

44%

Noticeable

increase

110%

voltage

Increase

21%

No

change

Decrease

17%

Increase

1%

Slight

decrease

Practically

no change

Decrease

1-2 points

Decrease

5-10 points

Decrease

5 points

Decrease

5-6 points

Increase

2-4%

Increase

10-12%

Increase 3-4

degrees C.

Increase

21%

Increase

slightly

Functions

of Voltage

(voltage)

2

Constant

1

(voltage)

2

(sync

speed slip)

voltage

(voltage)

2

90%

Voltage

Decrease

19%

No

change

Increase

23%

Decrease

1-1/2%

Decrease

2 points

Practically

no change

Increase

1-2 points

Increase

5 points

Increase

2-3 points

Increase

4-5 points

Increase

11%

Decrease

10-12%

Increase 6-7

degrees C.

Decrease

19%

Slight

decrease

Frequency Variation:

105%

frequency

Decrease

10%

Increase

5%

Practically

no change

Increase

5%

Slight

increase

Slight

increase

Slight

increase

Slight

increase

Slight

increase

Slight

increase

Slight

decrease

Decrease

5-6%

Slight

decrease

Slight

decrease

Slight

decrease

Function of

frequency

1

(frequency)

2

Frequency

(sync

speed slip)

1

frequency

95%

frequency

Increase

11%

Decrease

5%

Practically

no change

Decrease

5%

Slight

decrease

Slight

decrease

Slight

decrease

Slight

decrease

Slight

decrease

Slight

decrease

Slight

increase

Increase

5-6%

Increase

slightly

Increase

slightly

Increase

slightly

1% phase

unbalance

Slight

decrease

Slight

decrease

Slight

decrease

2%

decrease

5-6%

decrease

1-1/2%

increase

Slight

decrease

2%

increase

2% phase

unbalance

Slight

decrease

Slight

decrease

Slight

decrease

8%

decrease

7%

decrease

3%

increase

Slight

decrease

8%

increase