Door and handle construction, Guidelines, Instructions – Rockwell Automation 1494F Flange Mounted Disconnect Switches Instructions User Manual

Page 6: Door and hardware construction

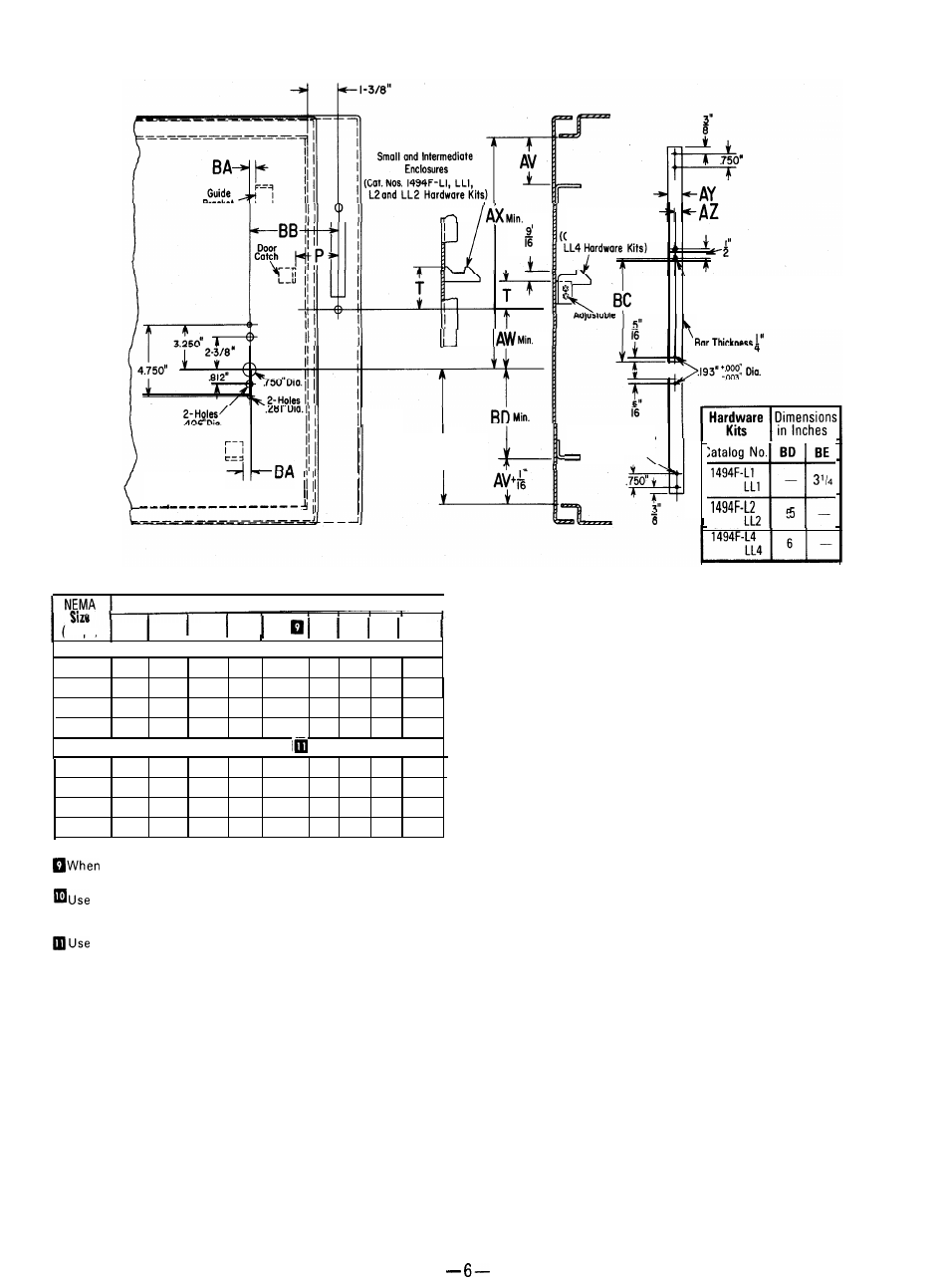

DOOR AND HARDWARE CONSTRUCTION

Large Enclosures

Cat. Nos. 1494F-L4 and

2-Holes

# IO-32 Tap

Nominal

C l e a r a n c e H o l e s

for 2-#1/4-20

Screws

I

BE Min.

N o .

B D B E

1494F-L1

LL1

-

LL2

-

I

- - - - - - - - - - - - -

2. Select the dimensions from above which apply to the

roller latching arrangement to be installed.

NOTE: Door catch supplied with all disconnects is not

to be used with these door hardware kits.

3. Locate holes in door to secure handle assembly.

4. Determine Dimensions “BA” and “AV” to locate

locking bar guide bracket(s).

5. Locate door catch using “P” and “T” dimensions.

Location varies with each hardware kit. On 1494F-L4

and 1494F-LL4 hardware kits, attach the adjustable

catch after the support bracket is located. NOTE: Door

catch and guide bracket(s) are made with projections

for welding to the enclosure door. However, if a

specific installation permits, holes can be drilled in

the door catch and guide bracket(s) using the projec-

tions as centers. Then, after proper location and

using them as templates, corresponding holes can

be drilled in the enclosure door. Door catch and

guide bracket(s) are then fastened to the enclosure

door with hardware furnished by user.

6. Establish the length of the top locking bar by measur-

ing Dimension “AX” and subtracting

3

/4

" for Kits L1,

LL1 , L2, and LL2; subtract 1

1

/

8

" for Kits L4 and LL4.

Determine the length of the bottom locking bar by

measuring Dimension “BE” and subtracting 3/4" for

Kits L2 and LL2; subtract 1

1

/8

" for Kits L4 and LL4.

Dimension “BC” is determined by measuring Di-

mension "AW" and adding 3

1

/2

" for Kits L1, LL1, L2,

and LL2; add 3%” for Kits L4 and LL4. Locate, drill,

and tap holes where necessary. NOTE: These stan-

dard mill rectangular locking bars are not supplied

with these kits.

7. The door locking hardware assembly can now be

attached to the door.

Dimensions In Inches

I

Amps)

P T AV AW AX AY AZ BA BB

I

I

SMALL & INTERMEDIATE ENCLOSURES

q

30 2

5/32

2

1/8

3

1/16

3 13

1/2

1/4

3/8

3

7/8

60 2

5/32

2

1/8

3

1/16

3 14

1/2

1/4

3/8

3

7/8

100 2

5/32

2

1/8

3

1/16

3

18

7/8

1/2

1/4

3/8

3

7/8

200

2

5/16

21/8

1/8

3

1/16

3

23

25/32

1

/2

1

/4

3/8

3

15/16

LARGE ENCLOSURES

30 2

1/4

1

9/16

3

11/16

3

1/8

13

1/

8

5/8

5/16

1/2

4

6 0 2

1/4

1

9/16

3

11/16

3

1/8

13

5/8

5/8

5/16

1/2

4

1 0 0 2

1/4

1

9/16

3

11/16

3

1/8

18

1/2

5/8

5/16

1/2

4

200 2

11/32

19/16

3

11/16

3

1/8

23

13/32

5/8

5/16

1/2

4

using the minimum wiring space for the maximum size wire

as shown on Page 2 Dimensions "S" and " Y "

with Hardware Kits 1494F-L1 and LL1 (top and side latching);

1494F-L2 and 1494F-LL2 (top and bottom latching); and 1494F-L3

(side latching accessory for 1494F-L2 and LL2).

with Hardware Kits 1494F-L4 and LL4 (top, side and bottom

latching).

GUIDELINES

Small Enclosures: 30” high or less with 2 or 3 point

latching. Intermediate Enclosures: 30” thru 48” high

with 3 point latching. Large Enclosures: Above 48”

high with 3 point latching.

INSTRUCTIONS

1. Check all minimum enclosure and door dimen-

sions required for installation. Refer to Pages

and above.