Rockwell Automation 14885P KwikLink Lite, Field Network Pressure-Welded Connectors User Manual

Page 2

2

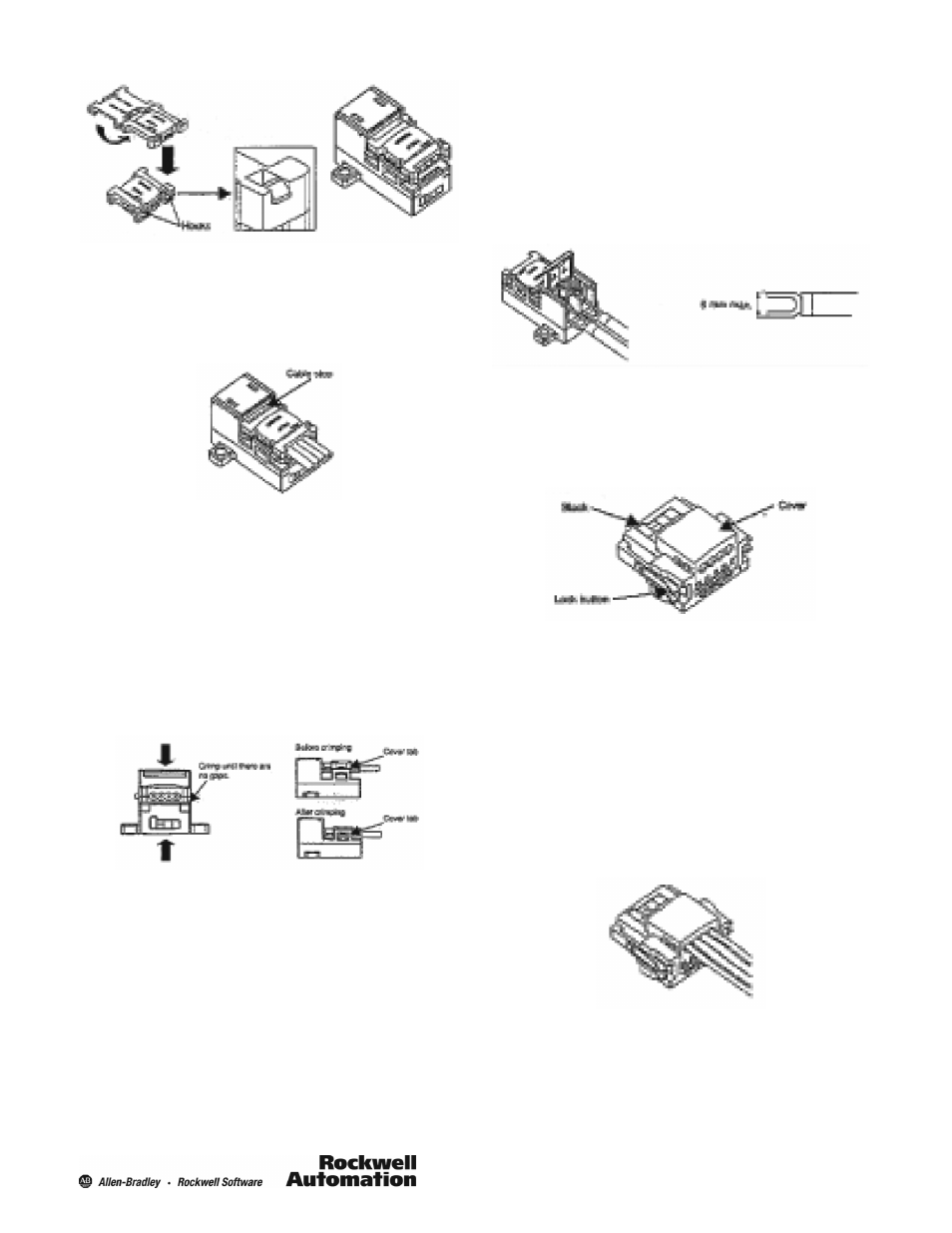

3. Attaching the Cable

S

Match the cable label with the cable colors and insert the

cable accordingly.

S

The back of the main unit acts as a cable stop. Insert the

cable all the way to the cable stop.

4. Crimping the Connector

S

Before crimping, be sure that the cable is inserted all the

way to the cable stop with no gaps.

S

Crimp at the center of the connectors using the DWT--A01

pliers.

S

After crimping, check to be sure that the cable was

crimped correctly.

Check to be sure that the housing lock is fully hooked

onto the cover tabs.

After crimping, check to be sure that there are no gaps

between the cover and the main unit.

Wiring Procedure for the End that Is Attached

Using Screws

1. Connect the Wires

S

Connect the wires with the crimp terminals to the terminals.

S

Connect crimp terminals for M3 screws. The appropriate

tightening torque is 0.30.5 Nm (2.6554.425 lbf in).

Use a screwdriver that is an appropriate size for the M3

screws.

Thin-Cable Flat-Cable Conversion Connector

Part Names

1485P--K1GK4

Wiring Procedure

1. Cutting the Cable

S

Cut the cable at a 90 angle to the length of the cable.

S

To prevent short circuits, be sure to cut the cable with a

sharp knife and be sure that there are no short conductor

wires protruding from inside the cable sheath.

2. Attaching the Cable

S

Match the cable label with the cable colors and insert the

cable accordingly.

S

The cover is semitransparent, which allows you to check to

be sure that the cable is fully inserted.

3. Crimping the Connector

S

Before crimping, be sure that the cable is inserted all the

way to the back and there are no gaps.

S

Crimp at the center of the connectors using the

1485AKCRIMP flat cable crimp tool.