Steps 3 and 4, 180a precharge contactor replacement, S1 t1 – Rockwell Automation 1336R REGEN 48,78,180A Precharge Contactor Repl. User Manual

Page 3: Rs t pe pe

1336 REGEN Precharge Contactor Replacement

3

1336 REGEN-5.14 May, 1998

CAT 1336R-VB180PRE-AN

SER A

118.7-143.7

AC INPUT

K W

VOLTS

A

PH

HZ

AC OUTPUT

DC OUTPUT

REFER TO USER MANUAL FOR

INSTALLATION INSTRUCTIONS

180.4

118.7-143.7

380-480

180.4 3

50/60

–

–

–

–

–

3

50/60

380-480

ALLEN-BRADLEY

MADE IN U.S.A.

UL

®

LIST

ED 966X

IN D

C O N T E

Q

UL

®

LIST

ED 966X

IN D

C O N T E

Q

C

®

R

S

T

PE

PE

!

DANGER

RISK OF SHOCK

REPLACE AFTER

SERVICING

R1

1

L1

3

L2

5

L3

S1

T1

TORQUE TERMINALS TO 275 LB-IN

USE 75˚C WIRE ONLY

13

14

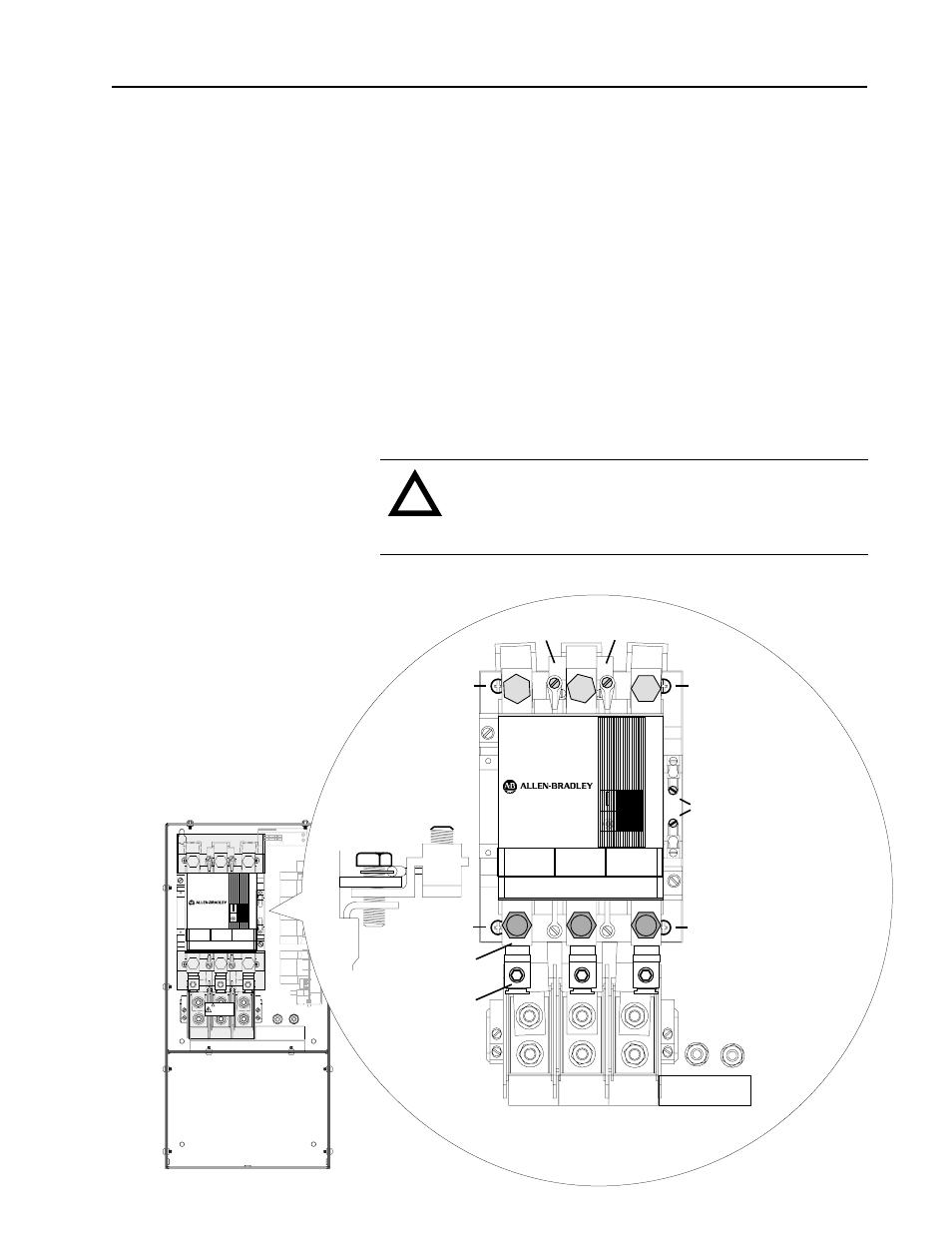

Steps 3 and 4

AC Coil Leads A1 ,A2

Mounting

Screw

Mounting

Screw

A1

A2

R1

1

L1

3

L2

5

L3

S1

T1

TORQUE TERMINALS TO 275 LB-IN

USE 75˚C WIRE ONLY

R

S

T

PE PE

Aux Contact

Leads 13 ,14

Set Screw

(3) Places

Mounting

Screw

Mounting

Screw

Lug Bolt

(3) Places

Set Screw

Lug Bolt

1.

Remove and lock-out all incoming power to the 1336 REGEN Line

Regeneration Package.

2.

Remove the Precharge Unit front cover. Measure the voltage at input

power terminals R1–S1–T1 and terminal block TB1 with a voltmeter to

ensure that no voltage is present.

3.

Disconnect all leads at the contactor and remove the (4) mounting

screws.

4.

Install the new contactor.

Torque the (4) contactor mounting screws to 2.6-4.1 N-m (23-36 lb.-in.).

Torque A1-A2 to 2.6-4.1 N-m (23-36 lb.-in.).

Torque L1-L2-L3 and the (3) R1-S1-T1 lug bolts at the bottom of the

contactor to 31.6 N-m (275 lb.-in.).

Torque the (3) R1-S1-T1 set screws to 0.9 N-m (8 lb.-in.).

Torque 13-14 to 2.6-4.1 N-m (23-36 lb.-in.).

180A

Precharge Contactor

Replacement

!

ATTENTION:

Replace any guards or shields previously

removed before reapplying power to the 1336 REGEN Line

Regeneration Package. Failure to replace guards or shields

may result in death or serious injury.

5.

Reinstall the Precharge Unit front cover.