Rockwell Automation 873P Programmable Ultrasonic Sensors User Manual

Page 3

3

Programming

These sensors will require programming using the

pushbutton at the rear of the sensor.

S

Setpoint P1 indicator is the yellow P1 LED

S

Setpoint P2 indicator is the yellow P2 LED

S

Echo/Alignment indicator is the green LED and indicates

that the sensor is receiving the proper signal from a

target.

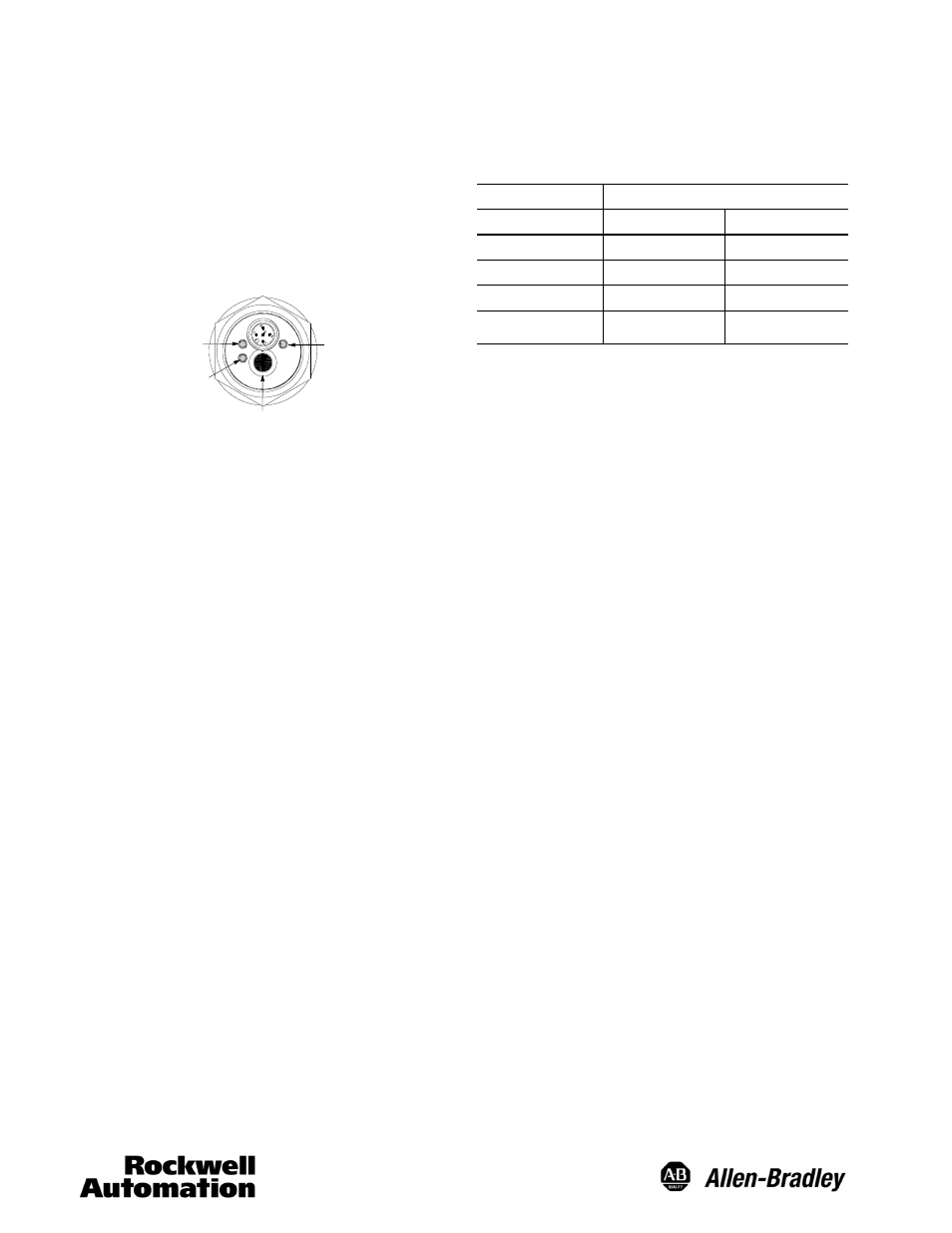

Connector View

ECHO

LED

P2

LED

P1

LED

Set Up

Pushbutton

S

Setpoint (P1) corresponds to the 0V DC or 4mA analog

output for Pin 5.

S

Setpoint (P2) corresponds to the 10V DC or 20mA

analog output for Pin 5.

S

The analog output can be programmed with either a

positive or negative slope depending on the position of

these setpoints. For a positive slope setpoint P1 will be

closer to the sensor than setpoint P2. For a negative

slope setpoint P2 will be closer than setpoint P1.

S

See the Analog Output graphs for details.

G

Setpoint (P1)—To set P1 depress the pushbutton

until the P1 and Echo LEDs are blinking

simultaneously. (See the pushbutton set time chart for

the approximate duration the pushbutton should be

depressed).

G

Release the pushbutton for setpoint P1 programming

mode. After release, the yellow P1 LED should be

blinking slowly.

G

Place the target at the P1 position and depress the

pushbutton to program the P1 switchpoint. The output

can be set for normally open or normally closed

operation. For a normally open output depress with

the P1 LED “ON”; for a normally closed output

depress with the P1 LED “OFF.”

G

Setpoint (P2)—To set P2 depress the pushbutton

until the P2 and Echo LEDs are blinking alternately.

Note that the P1 and Echo LEDs will start blinking first

and then the P2 and Echo LED will start blinking. (See

the pushbutton set time chart for the approximate

duration the pushbutton should be depressed.)

G

Release the pushbutton for setpoint P2 programming

mode while the P2 and Echo LEDs are blinking. After

release the yellow P2 LED should be blinking slowly.

G

Place the target at the P2 position and depress the

pushbutton to set the P2 switchpoint. For a normally

open output depress with the P2 LED “ON”; for a

normally closed output depress with the P2 LED

“OFF.”

Pushbutton Set Time (Seconds)

Model

Setpoint (P1)

Setpoint (P2)

873P- DCAV1S- D5

8

12

873P- DCAC1S- D5

8

12

873P- DCAV2S- D5

17

21

873P- DCAC2S- D5

17

21

Notes:

1. You have approximately one minute to set either P1 or

P2 once you are in the programming mode. After one

minute the sensor will exit the programming mode.

2. After the setpoints have been programmed into the

sensor, they are stored in the sensor memory

(EEPROM). Loss of power will NOT cause the sensor to

lose these setpoints.

3. To change the setpoint distances after they have been

programmed requires reprogramming the sensor.

Reprogramming each set point can be done independent

of the other.

4. The setpoints can be programmed in any order.

Operation Principle

Ultrasonic sensors utilize a transducer that emits bursts of

high frequency sound waves in a cone shaped beam

pattern. These pulses are reflected or “echoed” from the

target back to the sensor and detected by the transducer.

The device determines the distance from the sensor to the

target by measuring the length of time for this echo to

return. Programmable models have three outputs. The two

discrete outputs compare this duration to that of the near

and far limits as programmed by the user via the

pushbutton. The sensor outputs are switched at these limits

based on the time duration to receive the echo. The analog

output converts the time value to a DC current or voltage

(depending on the model) that is scaled between the

switchpoints. There is an unusable area, or deadband,

directly in front of the sensor since there is a necessary

time interval between transmission and detection of the

soundwave by the transducer. This is the minimum distance

at which the target can be detected.

Sensing Distance

Bulletin 873P programmable ultrasonic sensors are

available with the following sensing ranges: 150--1500mm

and 350--3500mm. The sensing ranges are determined

using an industry standard 100mm x 100mm flat steel

target.