Rockwell Automation 873P Analog or Discrete Ultrasonic Sensors User Manual

Page 3

3

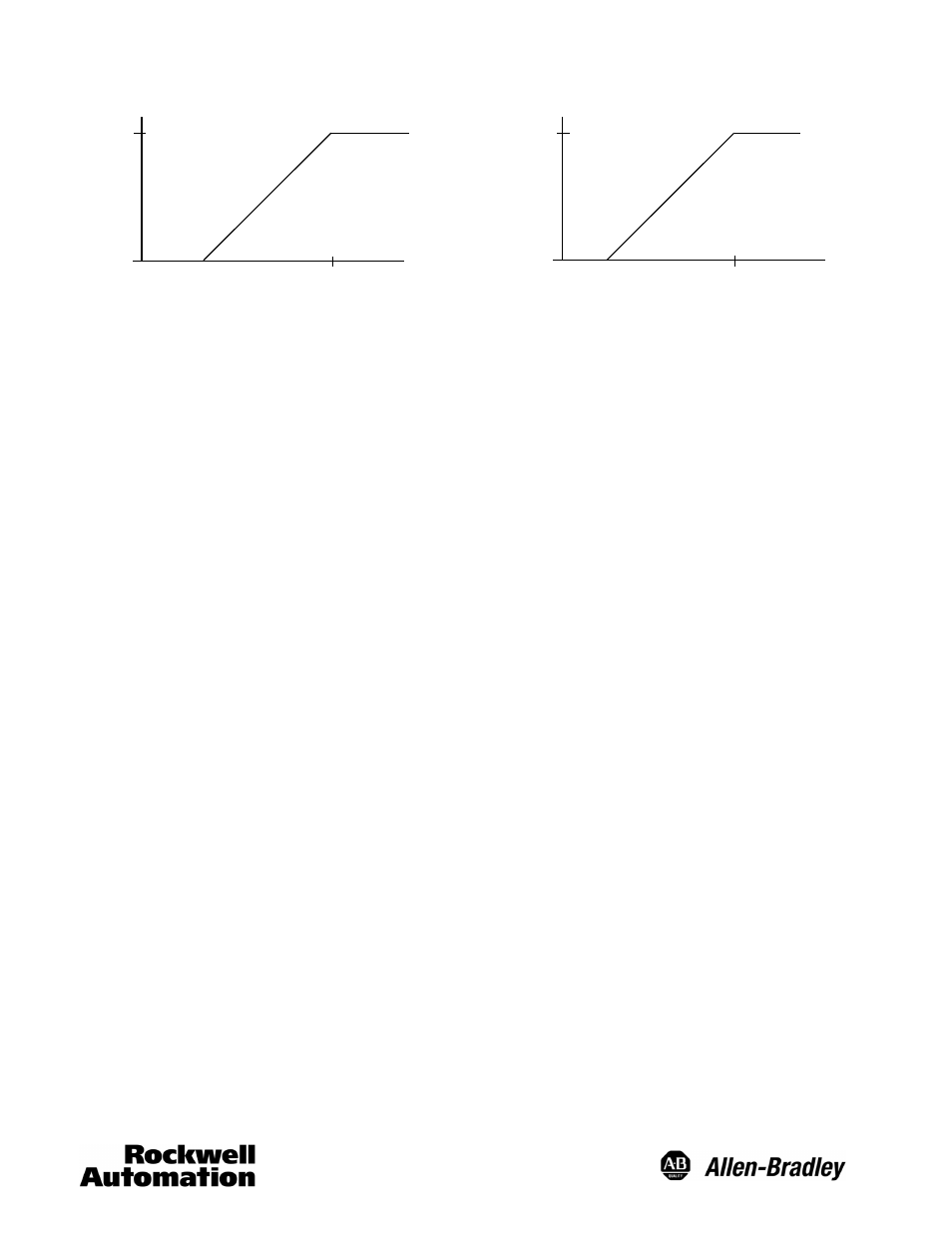

Analog Output

Analo

g

Cu

rr

en

t(

mA)

Anal

og

Vo

ltage

(V

DC)

Target Position—mm

20

100

600

200

1500

300

2500

Target Position—mm

0

10

100

600

200

1500

300

2500

4

Operation Principle

Ultrasonic sensors utilize a transducer that emits bursts of

high frequency sound waves in a cone shaped beam

pattern. These pulses are reflected or “echoed” from the

target back to the sensor and detected by the transducer.

The device determines the distance from the sensor to the

target by measuring the length of time for this echo to

return. Discrete models compare this duration to that of the

far limit which can be set by adjusting the potentiometer.

The output of the sensor is switched if the echo is returned

within this timeframe. The analog models convert the time

value to a DC current or voltage depending on the model.

There is an unusable area or deadband directly in front of

the sensor since there is a necessary time interval between

transmission and detection of the soundwave by the

transducer. This is the minimum distance at which the

target can be detected.

Sensing Distance

Bulletin 873P analog and discrete ultrasonic sensors are

available in three sensing ranges: 100--600mm,

200--1500mm, 300--2500mm. The sensing ranges are

determined using an industry standard 100mm X 100mm

flat steel target.

Target Considerations

Since the actual sensing distance to an object depends on

a reflected sound wave, target material, shape, size,

temperature, and position will influence operation; it is

possible that the sensing distance can be reduced or the

target may not be detected based on these characteristics.

The ideal target is a smooth, flat surface. Target material

that is not relatively sound reflective (fabric, foam rubber,

etc.) may be difficult to detect depending on the application.

Rounded or uneven objects can also be detected, but the

sensing distance may be reduced. For best performance,

the sensor should be aligned such that the sensor face is

parallel to the target surface.

Environmental Factors

The velocity of sound in air is dependent upon temperature

(sound waves travel faster at higher temperatures). Bulletin

873P ultrasonic sensors have internal temperature

compensation to adjust the ultrasonic frequency to

compensate for these changes in the ambient air

temperature. However, while this feature does compensate

for ambient temperature changes, temperature variations

within the sensing range due to convection currents,

heating/cooling elements, etc., may still divert or refract the

sound wave and adversely affect sensor performance.

Strong air turbulence can also influence the signal and

adversely affect the stability and overall sensor operation.

Humidity does not significantly affect ultrasonic sensor

operation, but changes in humidity can have a slight affect

in some instances due to the absorption of sound.

Mounting Considerations

The sensor must be securely mounted on a firm stable

surface or support. A mounting configuration that is

unstable or subject to excessive vibration may cause

intermittent operation.

A mounting location should be chosen such that the sensor

faces directly toward the target’s surface (perpendicular to

the barrel axis of the sensor).

When using more than one 873P there is a potential for

cross-talk (mutual interference) between the sensors. As a

result, consideration should be given to the spacing

between the sensors. See the beam pattern chart for the

minimum acceptable distance between sensors that are

mounted side by side. When the sensors must be mounted

facing each other they should be separated by a distance at

least 4 times the maximum sensing range for the model.

If the sensors must be mounted close together due to

application requirements, the Hold or Synchronize

functions can be used to reduce cross-talk.

The Hold function stops the sensor from transmitting and

receiving ultrasonic pulses, which eliminates the potential

for cross-talk. This function also can be used to hold the

output to its existing state or value. For details see the Hold

function in the Wiring/Control Pin section.