Installation instructions, Technical specifications – Rockwell Automation 440N SensaGuard 18 mm Stainless Steel Barrel Installation Instructions User Manual

Page 3

Installation Instructions

Installation must be in accordance with the following steps and stated specifications and should be

carried out by suitable competent personnel. The unit is not to be used as a mechanical stop. Guard

stops and guides must be fitted. Adherence to the recommended maintenance instructions forms part

of the warranty.

This device is intended to be part of the safety related control system of a machine. Before installation,

a risk assessment should be performed to determine whether the specifications of this device are suit-

able for all foreseeable operational and environmental characteristics of the machine to which it is to

be fitted. Refer to Technical Specifications for Certification information and ratings.

ATTENTION:

The presence of spare actuators compromise the integrity of the safety sys-

tems. Personal injury or death, property damage or economic loss can result.

Appropriate management controls, working procedures and alternative protec-

tive measures should be introduced to control their use and availability.

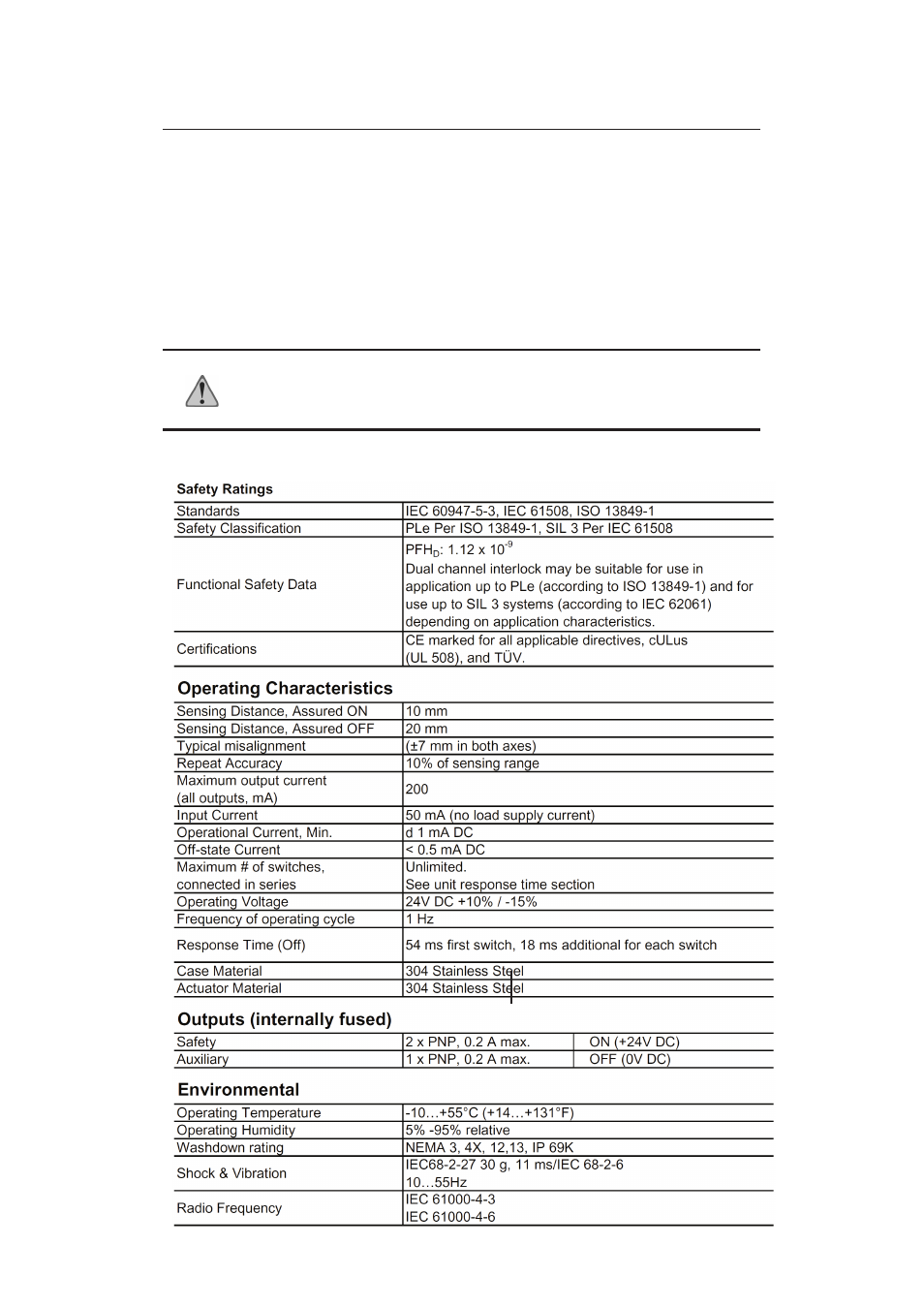

Technical Specifications

SensaGuard

TM

18 mm Stainless Steel Barrel Installation Instructions 3

PA-75056-181, Ver 05 March 2012