Rockwell Automation 800HL-EMP Selector Switches User Manual

Sheet size ver of 2 1

INSTALLATION INSTRUCTIONS

800HL-EMP SELECTOR SWITCHES

FOR NEMA TYPE 7 [3/8" (9.5) TO 2-1/2" (50.8)

PANELS] AND TYPE 9 [7/32" (7.2) TO 2-1/2" (50.8) PANELS]

�

(Dimensions shown in parentheses are in millimeters)

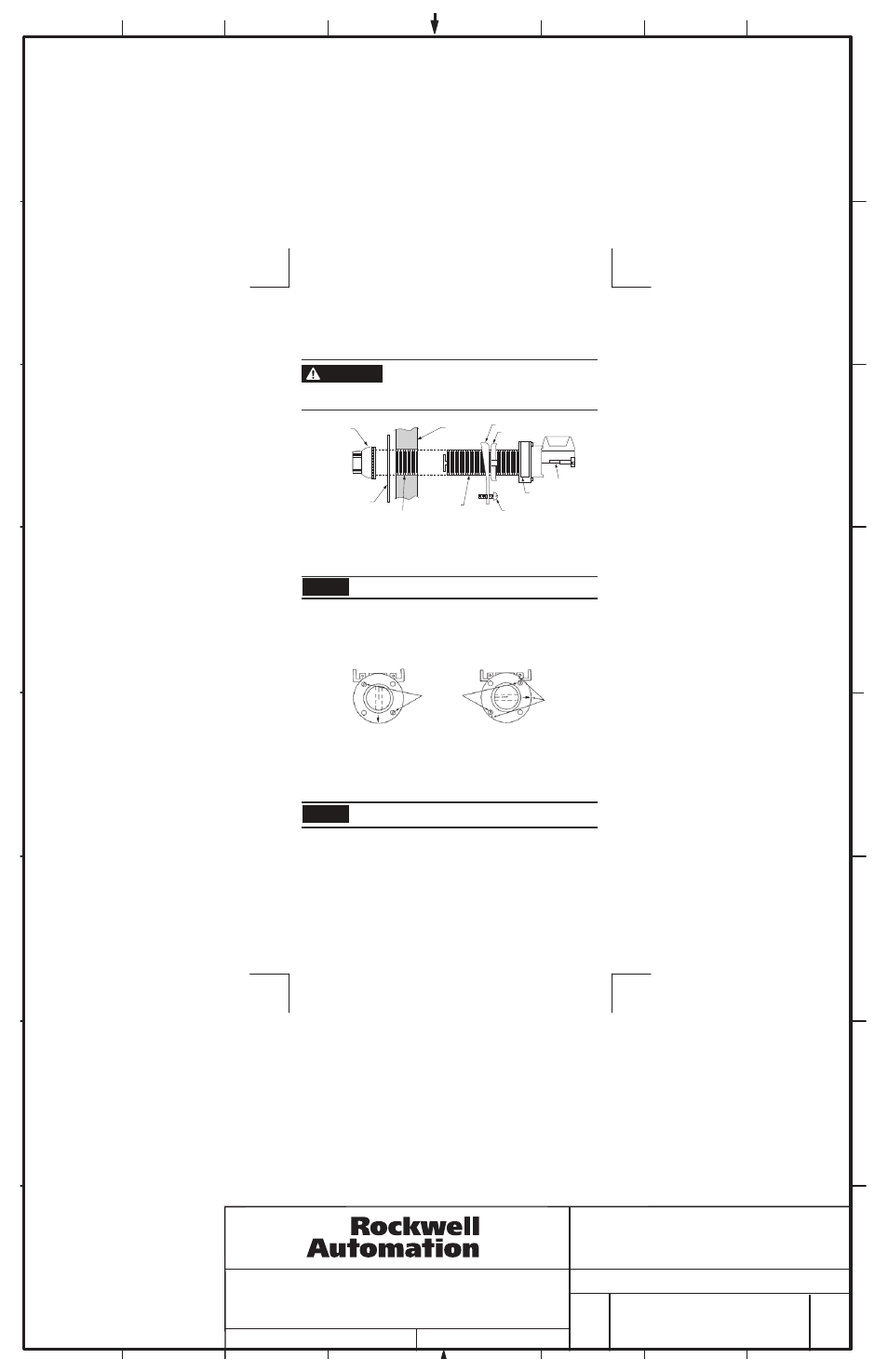

Installation: See Figure 1 for illustrated assembly

1. Place securing ring and/or adjusting nut as supplied on unit as shown above and thread unit into

panel until bushing extends approximately 9/32" (7.1) [3 to 4 threads] past front of panel. 7/32" (5.6)

[2 to 3 threads] if a legend plate is not to be used.

The specified extension of the bushing is necessary to provide engagement of the operating knob.

2. To secure unit, rotate to assure electrical clearance and tighten adjusting nut and/or locking screw

securely. Where two units are mounted adjacent to each other, arrange securing rings to avoid

interference.

3. Place legend plate, if used, over mounting bushing.

NOTE: Remove knob, lever or key before modification.

1. With a felt pen or crayon, make reference marks on the mounting bushing to identify the side

adjacent to the nameplate and the holes in which the flat-head screws are assembled.

2. Remove the two flat-head screws and lift the mounting bushing straight off of the base. Do not twist.

Do not rotate any parts within either the base assembly or the mounting bushing while these two

subassemblies are separated from each other, as this can cause incorrect switch operation after

reassembly.

3. 2 and 3 position selector switches: While separated from the base, turn the mounting bushing

counterclockwise 90° and reassemble the unit.

4 position selector switches: While separated from the base, turn the mounting bushing clockwise

90° and reassemble the unit.

NOTE: In the proper position originally - used mounting screw holes will be aligned with tapped holes in

the base.

4. Reassemble and torque the two flat-head screws to 8 ± 1 lb.-in.

5. Check the switch for proper operation and correct contact action.

To assemble the operating knob, align the colored insert with the rivet of the shaft plate (see Figure 3).

Tighten the knob assembly onto the mounting bushing. Knob assembly should clamp legend plate

tightly when properly assembled.

FLAT HEAD

SCREWS

Device For Vertical Mounting

Front View

Device For Horizontal Mounting

Front View

REFERENCE MARKS

LEGEND PLATE

MOUNTING

BUSHING

LOCKING SCREW

NAMEPLATE

CONTACT BLOCK

STANDARD

KNOB

Figure 1

Figure 2

B-vertical.ai

1

2

3

4

5

6

7

8

CONFIDENTIAL AND PROPRIETARY INFORMATION. THIS DOCUMENT

CONTAINS CONFIDENTIAL AND PROPRIETARY INFORMATION OF

ROCKWELL AUTOMATION, INC. AND MAY NOT BE USED, COPIED OR

DISCLOSED TO OTHERS, EXCEPT WITH THE AUTHORIZED WRITTEN

PERMISSION OF ROCKWELL AUTOMATION, INC.

800HL-EMP SELECTOR SWITCH

INSTALLATION

INSTRUCTION SHEET

10000008895

Sheet

Size

Ver

Of

2

1

B

01

Dr.

Date

G. Ushakow

06-08-08

To avoid damage to equipment or injury to personnel, electrical

power must be off before and during installation and maintenance.

Maintain ½" (12.7) minimum clearance through air between

current-carrying parts and enclosure.

WARNING

NOTICE

NOTICE

PANEL

� �

ADJUSTING NUT

SECURING RING

�

�