Rockwell Automation 140U Q, M Frame CB Installation and Operation for Thermal Magnetic Trip Units User Manual

Warning

40752-077(2)

Effective 5/02

DO NOT ATTEMPT TO INSTALL OR PERFORM

MAINTENANCE ON EQUIPMENT WHILE ITS IS

ENERGIZED. DEATH, SEVERE PERSONAL INJURY,

OR SUBSTANTIAL PROPERTY DAMAGE CAN

RESULT FROM CONTACT WITH ENERGIZED

EQUIPMENT. ALWAYS VERIFY THAT NO VOLTAGE IS

PRESENT BEFORE PROCEEDING WITH THE TASK,

AND ALWAYS FOLLOW GENERALLY ACCEPTED

SAFETY PROCEDURES.

ALLEN-BRADLEY IS NOT LIABLE FOR THE

MISAPPLICATION OR MISINSTALLATION OF ITS

PRODUCTS.

The user is cautioned to observe all recommendations,

warnings, and cautions relating to the safety of personnel

and equipment as well as all general and local health and

safety laws, codes, and procedures.

The recommendations and information contained herein

are based on Allen-Bradley experience and judgement,

but should not be considered to be all-inclusive or cover-

ing every application or circumstance which may arise. If

any questions arise, contact Allen-Bradley for further

information or instructions.

1. INTRODUCTION

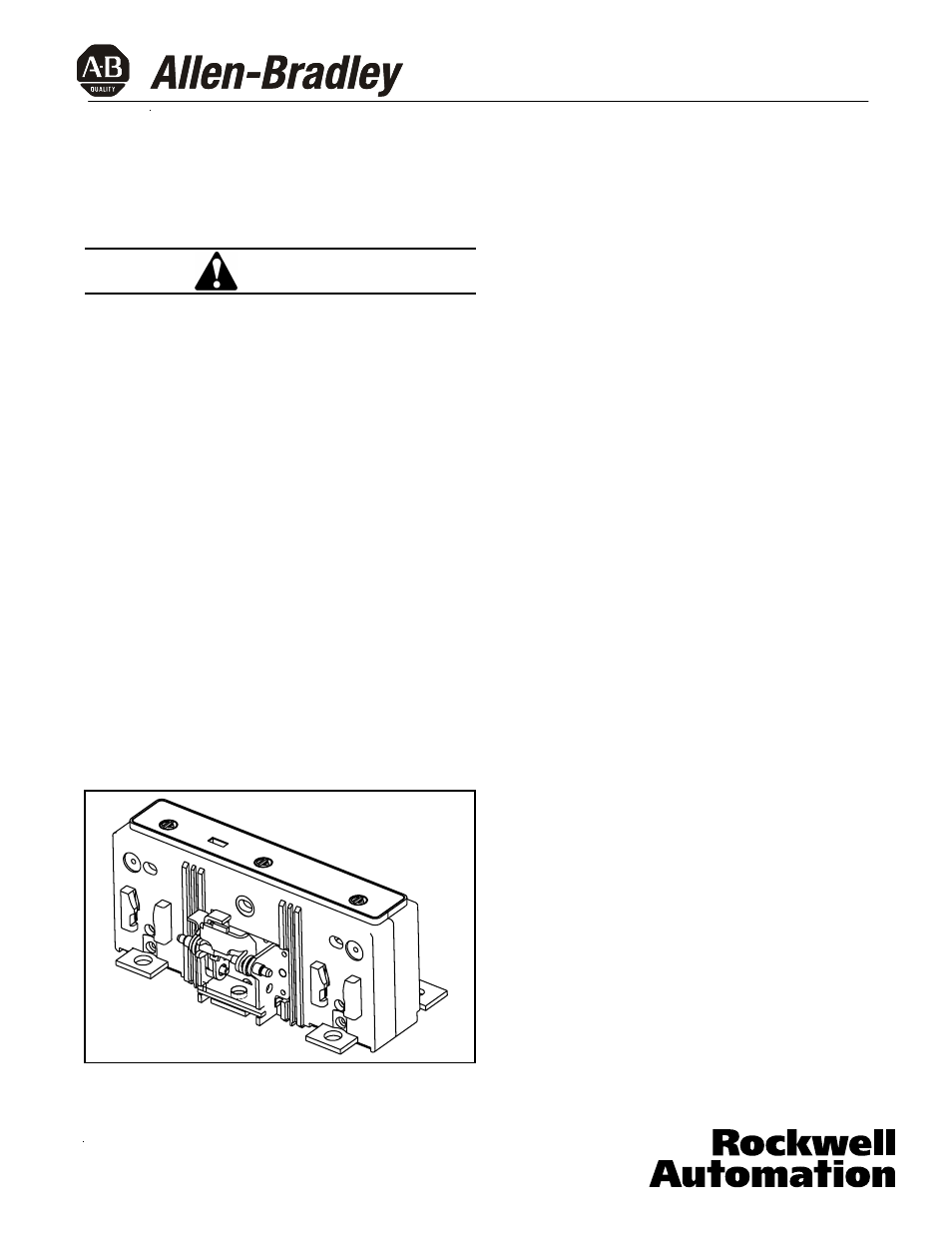

Fig. 1-1 Q-Frame and M-Frame Circuit

Breaker Thermal-Magnetic Trip Unit

General Information

Trip units for Q-frame and M-frame circuit

breakers (Fig. 1-1) are available in two types:

thermal-magnetic trip functions, described in this

instruction leaflet or electronic trip functions,

covered in Instruction Leaflet 40752-072. Trip

units are listed in accordance with Underwriters'

Laboratories, Inc. Standard UL489 and satisfy the

applicable requirements of the International Electro-

technical Commission Recommendations for molded

case circuit breakers.

The trip unit includes either a fixed or an adjustable ther-

mal element for inverse time delay on overload and an

adjustable magnetic element for protection against short

circuits. In open air at 40°C, the trip unit continuously car-

ries a current (l

n

) equal to the ampere rating marked on

the trip unit nameplate without exceeding a 50°C rise at

the terminals. The National Electrical Code (USA)

requirements state that enclosed overcurrent protective

devices may be loaded to a maximum of 80 percent of

the open air rating (I

n

).

The trip unit cover is factory sealed to prevent tampering

with the calibration. Tables 1-1 and 1-2 list catalog num-

bers and electrical data for trip units.

Thermal Trip: The thermal element trips the circuit

breaker within 2 hours for an overload of 135 percent and

trips in less time for higher overloads. For all currents in

excess of the magnetic setting, the tripping action is

instantaneous. In the overload trip region (up to 6 x I

n

),

the trip current times are the same for AC or DC.

WARNING

Q and M-Frame Circuit Breaker

Instruction Leaflet for Installation and Operation for

Thermal Magnetic Trip Units

Bul. 140U

Magnetic Trip: The magnetic trip on each pole may be

adjusted by turning the adjustment button with a screw-

driver (see Fig. 2-3). In the magnetic trip region (above 6

x In), the trip current levels can be up to approximately 40

percent higher for DC than for AC, depending on the rat-

ing.

Note: Trip units are calibrated at 40°C, 50/60 Hz and

DC as noted. Consult Allen-Bradley for derating at

other frequencies and ambient conditions.