Rockwell Automation 871P VersaCube Proximity Sensor User Manual

Changing the sensing head position

Installation Instructions

871P VersaCube Proximity Sensor

IMPORTANT: SAVE THESE INSTRUCTIONS FOR FUTURE USE.

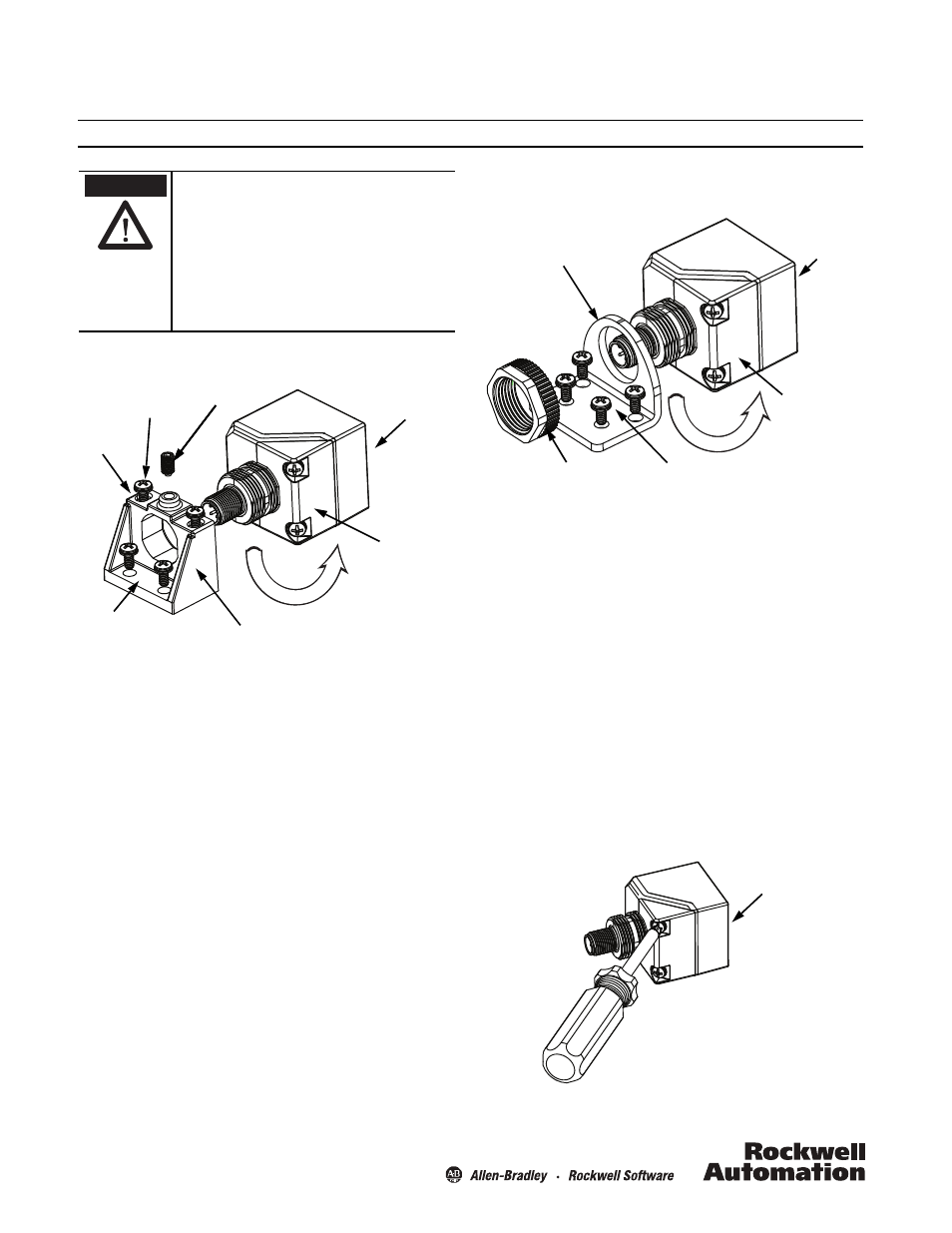

Mounting and Adjustment with the Zinc Bracket

Zinc Bracket Mounting

The VersaCube™ sensor and zinc bracket may come as a pre-

assembled unit.

Use either the slotted-hole mounting (A) or the through-hole

mounting (B). The slotted mounting holes allow fine adjustment

of sensing position by sliding the unit back and forth before

tightening the screws.

Follow these steps to install with the zinc bracket:

1. Mount the unit to a stable, flat surface using two screws (not

included). Recommended: 10-32 x 1.75 in. for slotted holes,

10-32 x 0.75 in. for through holes, or equivalent 5-mm screws.

2. Tighten the mounting screws to 0.9 N-m (8 in-lb), maximum.

Rotating the Sensor

1. Loosen the set screw with a 2.5-mm hex tool to remove the

sensor from the zinc bracket.

2. Rotate the sensor in 90-degree increments to the desired

orientation.

3. Insert the sensor back into the zinc bracket.

4. Tighten the set screw to 0.56 N-m (5 in-lb), maximum.

To change between top and side sensing positions, see

“Changing the Sensing Head Position,” at right.

Solid-state devices can be susceptible to radio frequency

interference (RFI) depending on the power and the

frequency of the transmitting source. If RF transmitting

equipment is to be used in the vicinity of the solid state

devices, thorough testing should be performed to assure that

the transmitter operation is restricted to a safe operating

distance from the control equipment and its wiring.

If a hazardous condition can result from unintended

operation of this device, access to the hazardous area should

be guarded.

ATTENTION

Set screw

Through-hole

mounting (B)

Zinc bracket

Slotted-hole

mounting (A)

Sensor face

45-degree

mounting base

Set screw

Set screw

Mounting screws

(not included)

Mounting with the Stainless Steel L-Bracket

(optional accessory)

Stainless Steel L-Bracket Mounting (optional)

1. Insert the sensor into the optional L-bracket in the desired

orientation.

2. Tighten the provided 22-mm plastic mounting nut to 0.9 N-m

(8 in-lb), maximum.

3. Mount the L-bracket to a stable, flat surface using at least two

screws (not included). Recommended: 10-32 x 0.75 in. or

equivalent 5-mm screws.

4. Tighten the mounting screws to 0.9 N-m (8 in-lb), maximum.

To change between top and side sensing positions, see

“Changing the Sensing Head Position,” below.

Changing the Sensing Head Position

To switch the sensing head between top and side sensing

positions, follow these steps:

1. Remove the sensor from the mounting bracket (zinc or

L-bracket).

Stainless steel L-bracket

(optional accessory)

22 mm plastic

mounting nut

Sensor face

45-degree

mounting base

Mounting screws

(not included)

Sensor face