Rockwell Automation 844C Incremental Encoder User Manual

Page 2

Publication 75008–133–01(B)

Document 910 990 103 489

February 2000

Printed in USA

Visit our web site at:

http://www.ab.com/sensors

Mounting Instructions

IMPORTANT: Be sure the mating shaft meets the

tolerance requirements shown in the tables in the

Dimensions section.

IMPORTANT: Be sure mating shaft is chamfered and

grease-free.

1. Loosen the screw on the clamping ring with the 2.5mm

hexagon socket wrench.

2. Slide the encoder onto the mating shaft until the flex mount

rests on the machine surface.

The encoder should slide freely onto the shaft; if not, do

not force. Check the shaft for interferences such as

gouges, burrs, rust or size.

If mounting holes already exist, proceed to Step 6.

3. Hold encoder firmly and mark the four mounting holes.

4. Slide the encoder off. Drill and tap the marked holes to

accept M4 (or equivalent) screws.

5. Slide the encoder back onto the shaft until the flex mount

rests on the machine surface.

6. Attach the encoder with four M4 (or equivalent) screws.

IMPORTANT: Do not stress the flex mount while

tightening the screws.

7. Tighten the clamping ring screw to 1.1 Nm (10 in–lbs).

8. Make the electrical connections according to the table

under Electrical Connections.

IMPORTANT: Wiring must be in accordance with the

National Electric Code and applicable local codes and

ordinances.

9. Apply the specified voltage.

Electrical Connections

Function

Line Driver

Wire Color

Open Collector

Wire Color

V DC

Red

Red

Common

Blue

Blue

A Output

White

White

B Output

Pink

Pink

Z Output

Violet

Violet

A Output

Brown

NC

B Output

Black

NC

Z Output

Yellow

NC

Shield

Drain Wire

Drain Wire

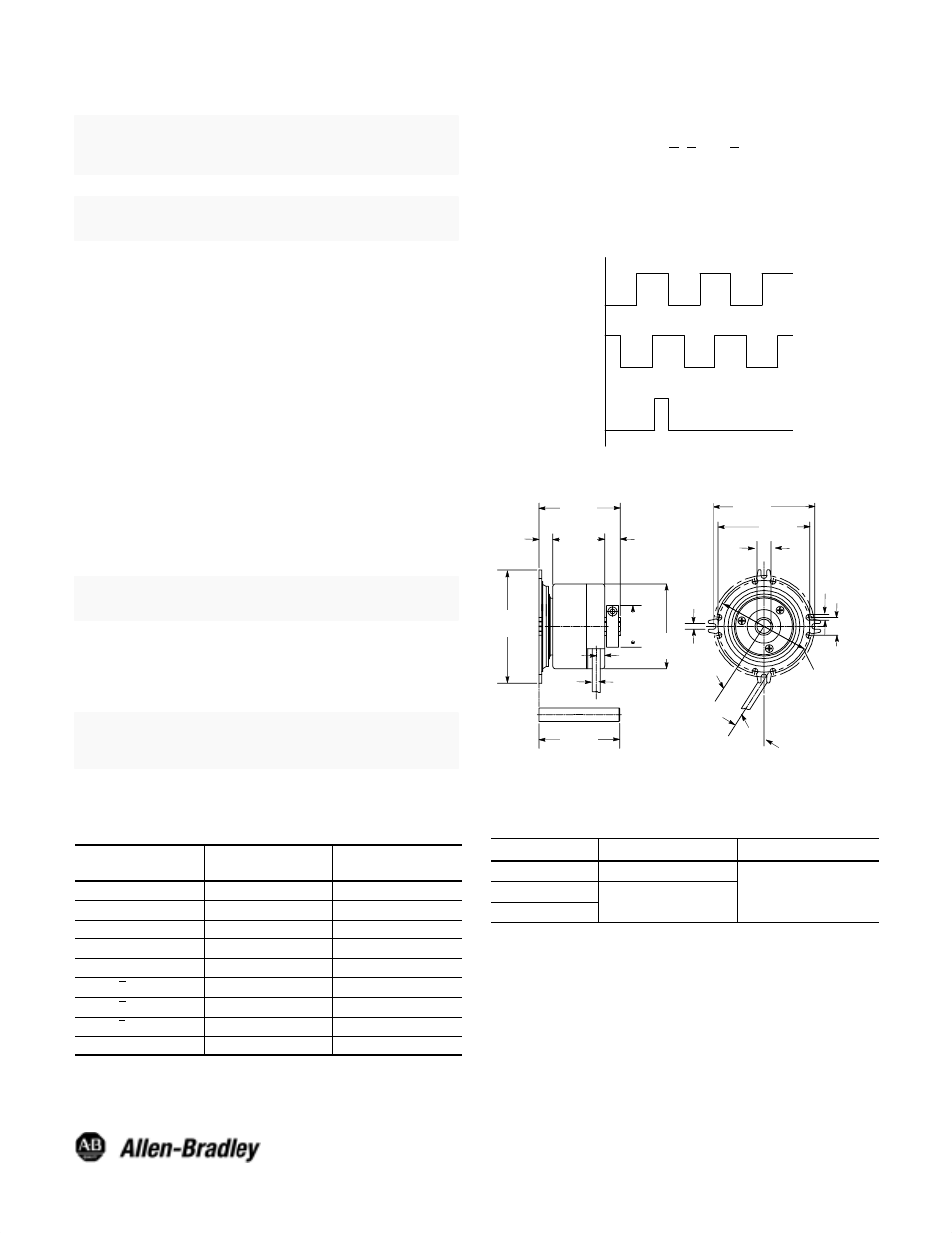

Output Waveforms

1. Channel A leads Channel B for clockwise rotation when

viewed from face of the encoder.

2. Complementary signals (A, B, and Z) are supplied only on

units with line drivers.

3. Marker Pulse is 1/4 cycle and is gated on the positive-

going edge of Channel B for clockwise rotation.

A

B

Z

Channel

Dimensions—mm

68

(2.68)

DIM

X"

12

(0.47)

4.2

(0.17)

32.5_

20.4

(9.80)

∅

29.5

(1.16)

6

(0.24)

11

(0.43)

9.8

(0.37)

Bulletin 844C

57.8

(2.28)

37

(1.46)

80.8

(3.18)

57

(2.24)

min

∅

5.5

(0.22)

∅

60

(2.36)

3.4

(0.13)

65

(2.56)

72

(2.84)

844C Mating Shaft Tolerance—mm (inches)

Bore

Diameter

Length

6mm to 10mm

+0.0/-0.015 (+0.0/-0.0006)

3/8I

0 0/ 0 018 ( 0 0/ 0 0007)

11.0/25.0 (0.433/0.984)

1/2I

+0.0/-0.018 (+0.0/-0.0007)

11.0/25.0 (0.433/0.984)