Rockwell Automation 802PR Type LA and Type XA, Series C Installation Instructions User Manual

Important: save these instructions for future use

Installation Instructions

Bulletin 802PR — Type LA and Type XA — Series C

IMPORTANT: SAVE THESE INSTRUCTIONS FOR FUTURE USE.

HAZARDOUS LOCATION SWITCHES — Switches for hazardous

locations meet Division 2; Class I Groups A, B, C, & D; Class II,

Groups F & G; and, Class III requirements. For additional

information refer to Publication GI-2.8 — A Summary of

National Electrical Code Requirements for Hazardous Locations.

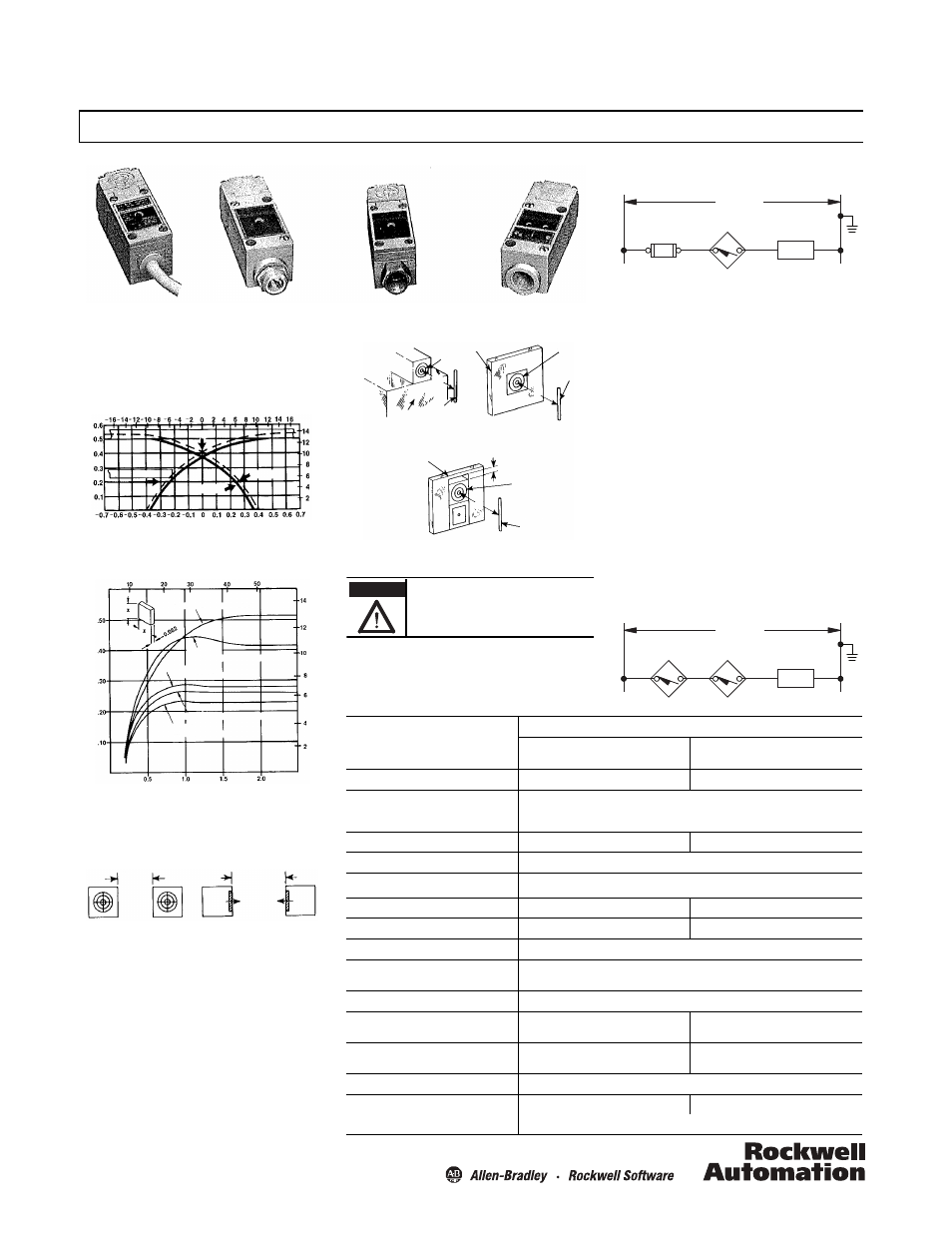

Figure 1: Typical sensing characteristics

Effects of Target Size and Materials on Sensing Distance

Figure 2: Typical sensing distance vs. target size for various metals

SPACING BETWEEN SWITCHES — When installing switches

side-by-side or face-to-face, the minimum spacings in Figure 3

should be maintained.

EFFECTS OF NEARBY METAL SURFACES ON SENSING

DISTANCES — The sensing distance will increase if the

proximity switch is installed so that metal is adjacent to the

sensing head surfaces as illustrated in Figure 4.

Prewired cable

Threaded conduit

opening

Prewired

receptacle

Conduit coupler

(Millimeters)

(Inches)

(Mi

llimeters)

Se

ns

in

g Distan

ce (in

ches)

Target

Release

Operate

Target

Square Target Size (x in Inches)

(Mi

llime

te

rs

)

Half Hard Cold

Aluminum (Alloy #1100-H14)

Cold Rolled Low Carbon

Cold Rolled

(Millimeters)

Head

O

n Se

ns

in

g Di

st

an

ce

(i

nc

he

s)

Stainless Steel (AISI 304)

Half Hard

Brass (Alloy 260 ASTM

Rolled Copper (ASTM-

Sensing Head Facing

Sensing Faces in Same Plane

3 in. minimum

2 in. minimum

Figure 4: Effects on nearby metal surfaces on sensing distances.

WIRING — Connect the proximity switch and load as shown in

Figure 5 using AWG #18 through #14 wire (1.0/1.5 mm

2

). The LED

of the switch will be ON when the load is energized.

SPECIFICATIONS

Description

Output Mode

Fixed

Normally Open

Programmable

Normally Open/Normally Closed

Operating voltage range

102…132V, 50/60 Hz

60…132V, 50/60 Hz

Load current

Max. continuous: 1 A to +40°C linearly derated to 0.5 A at +75°C

Max. inrush: 10 A, 1 second max.

Min.: 0.025 A

Max. leakage current (load off)

0.0065 A

0.0035 A

Max. voltage drop (load on)

7.5V

Operating temperature range

-25…+75°C (-13…+167°F)

Max. operate time

25 ms

25 ms

Max. release time

35 ms

25 ms

Delay on power-up target present

20 ms, typical (no output occurs with target absent)

Sensing distance

Steel: 0.525 in. +10% -5%. Refer to Figure 1

Nonferrous metals: 0.25 in. typical

Hysteresis (operate — release differential)

0.075 in. max.

Sensing distance drift with temperature

±5% 0…+75°C (32…167°F)

±10% -25…+75°C (-13…167°F)

±5% +15…+50°C (59…122°F)

±10% -25…+75°C (-13…167°F)

Max. sensing distance drift with voltage

±0.5% 102…132V

±1% 90…132V

±3% 60…132V

Repeat accuracy (10 successive operations)

0.001 in. max. deviation at constant temperature and supply voltage

Operating speed

(operations per minute)

1000

1200

Based on max. operate and release time

Sensing

Face

Metal

Sensing

Face

Target

Target

Target

Metal

Metal

Sensing

Face

D

D

D

1/4 in. Clearance

Figure 4a: Metal adjacent to one

side of head. Sensing distance D

increases approximately 2%.

Figure 4b: Metal surrounds head.

Sensing distance D increases

approximately 10%.

Figure 4c: Metal surrounds switch. Sensing

distance D increases approximately 8%.

WARNING

If a hazardous condition can result from

unintended energization of this device, access to

the sensing area should be guarded.

CONNECTION DIAGRAM

Figure 5: Typical wiring diagram

NOTE: To guard against the load remaining energized when the

switch is in an open condition, the minimum load release current

must be greater than the maximum leakage current of the

proximity switch.

GROUNDING — The Bulletin 802PR does not require a ground

connection. The load side of the110/120V AC source can be

grounded as indicated in the connection diagram.

SHORT CIRCUIT PROTECTION — A fuse is recommended in the

circuit to provide short circuit protection for the switch. Use a fast

acting Type KAW10 or KAX10 fuse.

SERIES CONNECTED SWITCHES —

Normally Open Fixed Output — Do not connect two or more

of the switches in series. Erratic operation may result.

Programmable Normally Open/Normally Closed Output

— Two switches can be connected in series with a load. For

proper operation, the operating load voltage must be less than or

equal to the minimum supply voltage less the sum of the on-

state voltage drops across the series connected proximity

switches. The load will be energized when the OUTPUT LEDs of

both proximity switches are ON.

CONNECTION DIAGRAM

Proximity

Switch

LOAD

Fuse

(if used)

(110/120V AC

L

1

L

2

LOAD

(110/120V AC

L

1

L

2