Adjustment checklist dimensions – Rockwell Automation 194RC-Nxxxx NFPA 79 Compliant Cable Operated Disconnect User Manual

Page 3

Situation:

Handle and Cable Operated Mechanism turns ON, but disconnect switch does not transition to ON.

Adjustment:

Loosen the lifting washer / nut while tightening the washer / lockwasher / nut, two or three turns should be sufficient (see Figure 1-5).

Check the OFF position of the actuator mechanism, that the lifting nut and sleeve of cable do not come into contact

with the bulkhead connector (Figure 1-5). If they do, move bulkhead connectors accordingly.

Situation:

Handle and Cable Operated Mechanism turns OFF, but disconnect switch does not transition to OFF.

Adjustment:

For the Cable Operated Disconnect Mechanism, loosen the washer / lock-washer / nut until the Disconnect Switch turns OFF with

positive action. Tighten both nuts and recheck for ON and OFF positions (Figure 1-5).

Be certain after adjustment to have a minimum of 1 thread past the washer / lockwasher / nut assembly (Figure 1-5).

If any other adjustment problems should arise, contact your local Allen-Bradley representative.

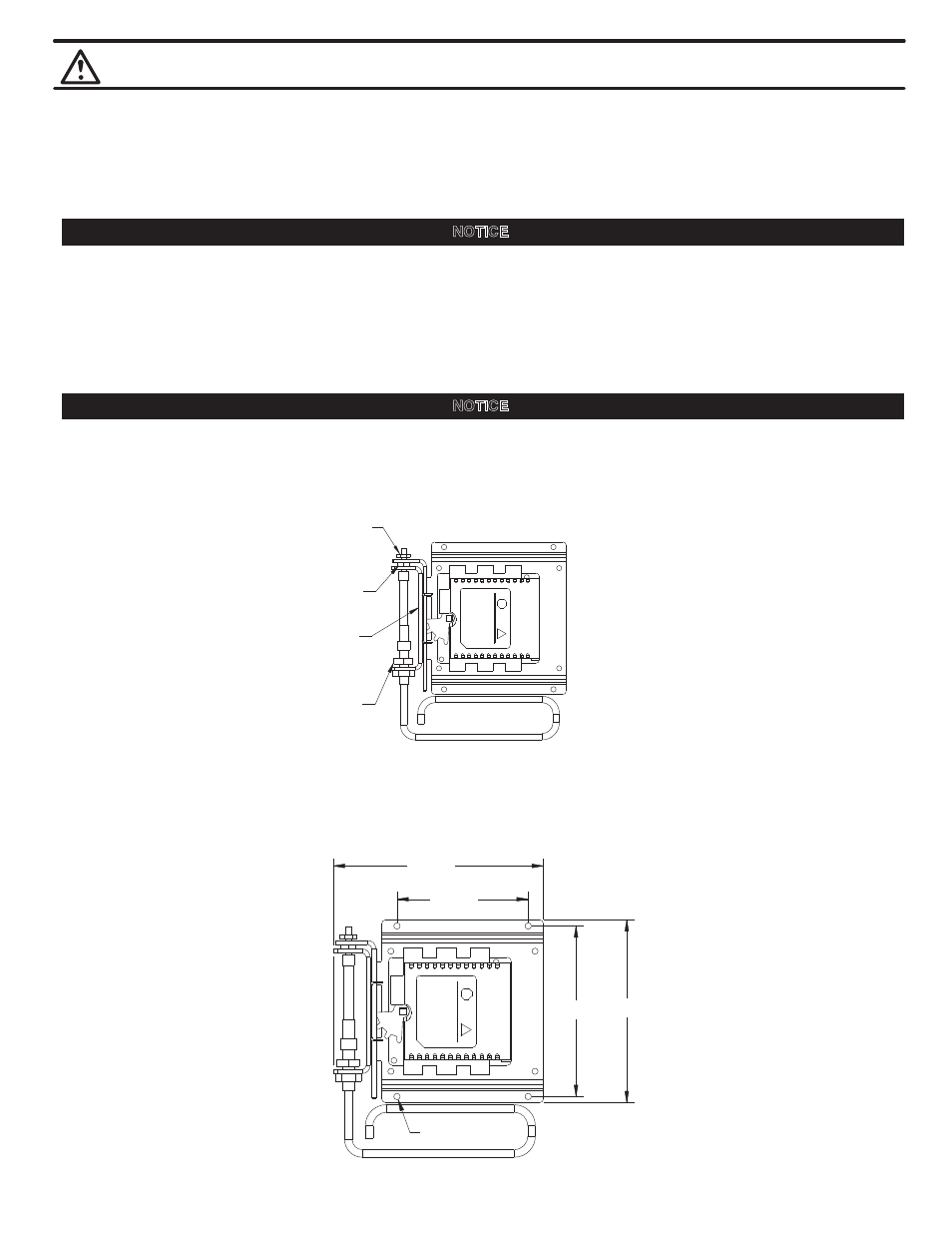

Figure 1-5 Cable Operated Disconnect Mechanism

Adjustment Checklist

Dimensions

6.891

4.300

5.590

ø .210

5.990

(3)

Washer / Lockwasher / Nut

Tighten to 40 - 45 lb-in

Lifting Washer / Nut

Bulkhead Connector

Tighten to 65 - 70 lb-in

Slider

ATTENTION: Before any installation or maintenance is performed, make sure that the disconnect switch is not energized.

NOTICE

NOTICE