Rockwell Automation 808 SPEED SWITCHES User Manual

Speed switches, Instructions

BULLETIN

INSTRUCTIONS

808

SPEED SWITCHES

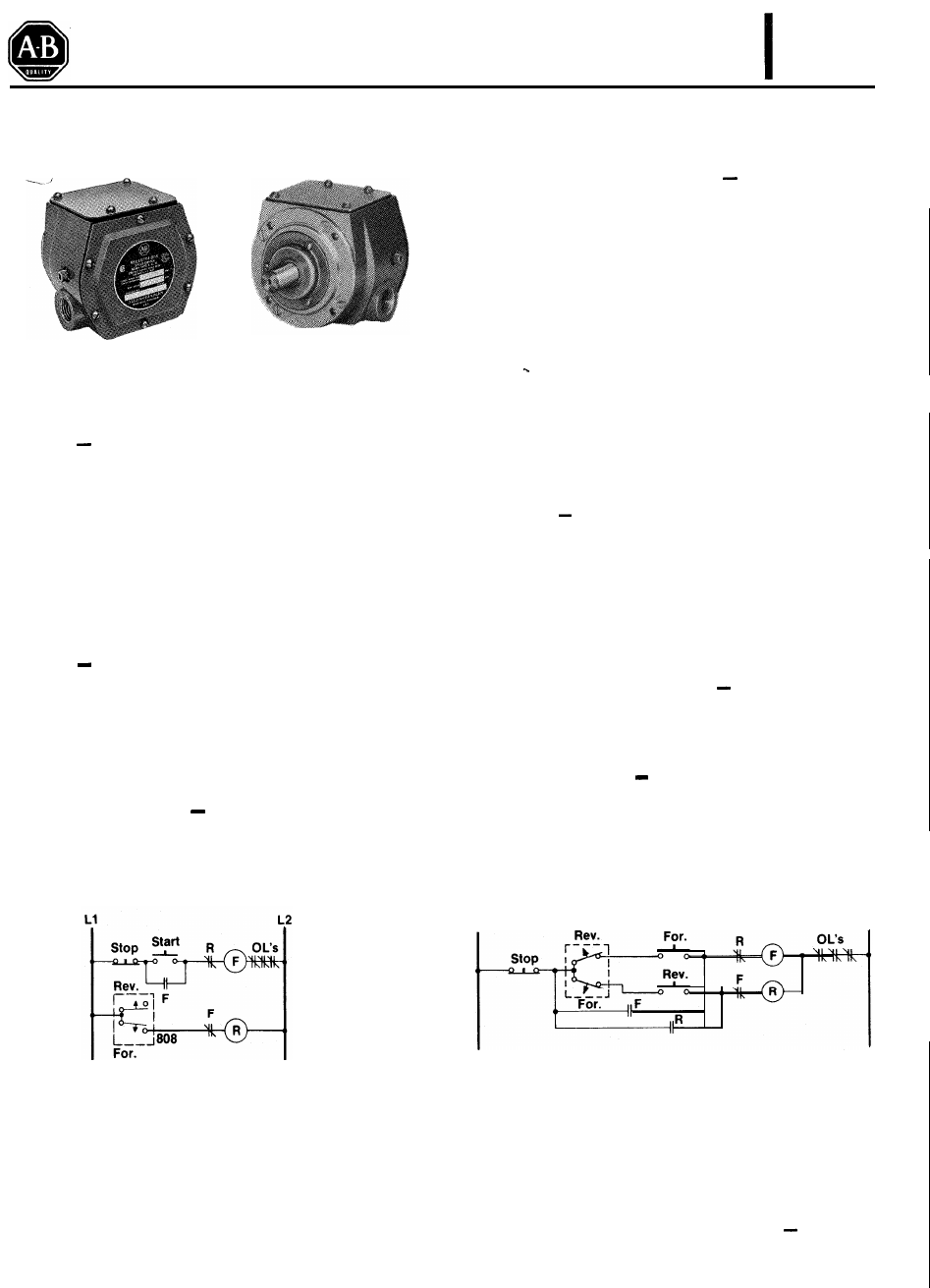

Rear View of Speed Switch

Front View of Speed Switch

Less Lockout Solenoid and

Less Lockout Solenoid and

Mounting Bracket

Mounting Bracket

NEMA Type 1, 4 and 13 Enclosure

NEMA Type 1, 4 and 13 Enclosure

DESCRIPTION

The Bulletin 808 speed switch is a pilot device

which is used with an automatic starter arranged for reversing

or plugging duty to provide plugging orantiplugging of squirrel

cage motors. This device can also be used as a speed sensing

switch, or to indicate direction of rotation of a driven shaft.

Plugging is a control function that provides braking by

reversing the motor. The phase sequence is reversed so that

the motor develops a counter-torque that exerts a retarding

force. Antiplugging protection is the effect of a control device

that operates to prevent the application of counter-torque by

the motor until the motor speed has been reduced to an

acceptable value.

PLUGGING

When applied in a suitable plugging application

such as the circuit shown in Figure 1, the switch with normally

open contacts is used. The Bulletin 808 speed switch is

designed to automatically interrupt reverse braking power as

the motor approaches zero speed. The speed at which the

contacts operate can be adjusted so as to avoid coasting or

reverse rotation of the motor. The contacts can be wired for

plugging in either or both directions.

TYPICAL PLUGGING CIRCUIT

Bulletin 808 speed switch used

with a reversing starter to bring a motor to a fast stop.

NOTE:

See applicable standards, codes, and laws for all

applications.

FIGURE 1

Forward

Reverse

PRECAUTIONS IN PLUGGING APPLICATIONS

T h e r e a r e m a n y

advantages in plugging a motor to a stop, however, care must

be taken that these advantages are not lost through misapplica-

tions. The following information should be considered before

deciding to use a plugging control.

1 . When plugging a motor to a stop, full load motor current

may be greatly exceeded. The electrical supply must be

able to handle the excess load.

2. The resultant forces of a plugged stop may be too great for

the driven machine to withstand. For example, a twisted or

broken shaft may result.

.

3. The motor may not withstand braking duty. The duty cycle

and load must be considered and the motor manufacturer

should be consulted to determine if a particular motor is

adequate for plugging duty.

NOTE:

See applicable standards, codes, and laws for all

applications.

ANTIPLUGGING

For this application, the switch with normally

closed contacts is used. The speed switch is designed to keep

the reverse circuit open until the speed of the driven machine

has decreased to a predetermined value. At this speed the

contacts are designed to close, permitting reverse energization

to be applied manually, or automatically when using a second

speed switch arranged for plugging duty. Mechanical braking

can also be used. The speed switch can be used for

antiplugging control in either or both directions. See Figure 2.

PRECAUTIONS IN ANTIPLUGGING APPLICATIONS

The speed switch

must be adjusted so that contact closure does not occur before

the speed of the machine is reduced to a safe level for

secondary braking.

TYPICAL ANTIPLUGGING CIRCUIT

This circuit is used in cases

where damage would result from a sudden reversal of power.

The speed switch contacts are designed to keep the reverse

circuit open until the motor has coasted to a preset speed.

NOTE:

See applicable standards, codes, and laws for all

applications.

L1

L 2

FIGURE 2

Publication 808-5.1 June, 1980

Supersedes

Publication 8084.1 Dated July, 1978

Document Outline

- Speed Switches

- Description

- Plugging

- Typical Plugging Circuit

- Precautions in Plugging Applications

- Antiplugging

- Precautions in Antiplugging Applications

- Typical Antiplugging Circuit

- Speed Sensing and Direction of Rotation

- Precautions

- Typical Conveyor Sequencing Circuit

- Coupling

- Precautions

- Adjustment

- Plugging

- Antiplugging

- Speed Sensing and Direction of Rotation

- Wiring Instructions

- Mounting

- Maintainance

- Lockout Solenoid

- Publication No.