Dr. date, Sheet size ver of 2 2 – Rockwell Automation 800H Potentiometer User Manual

Page 2

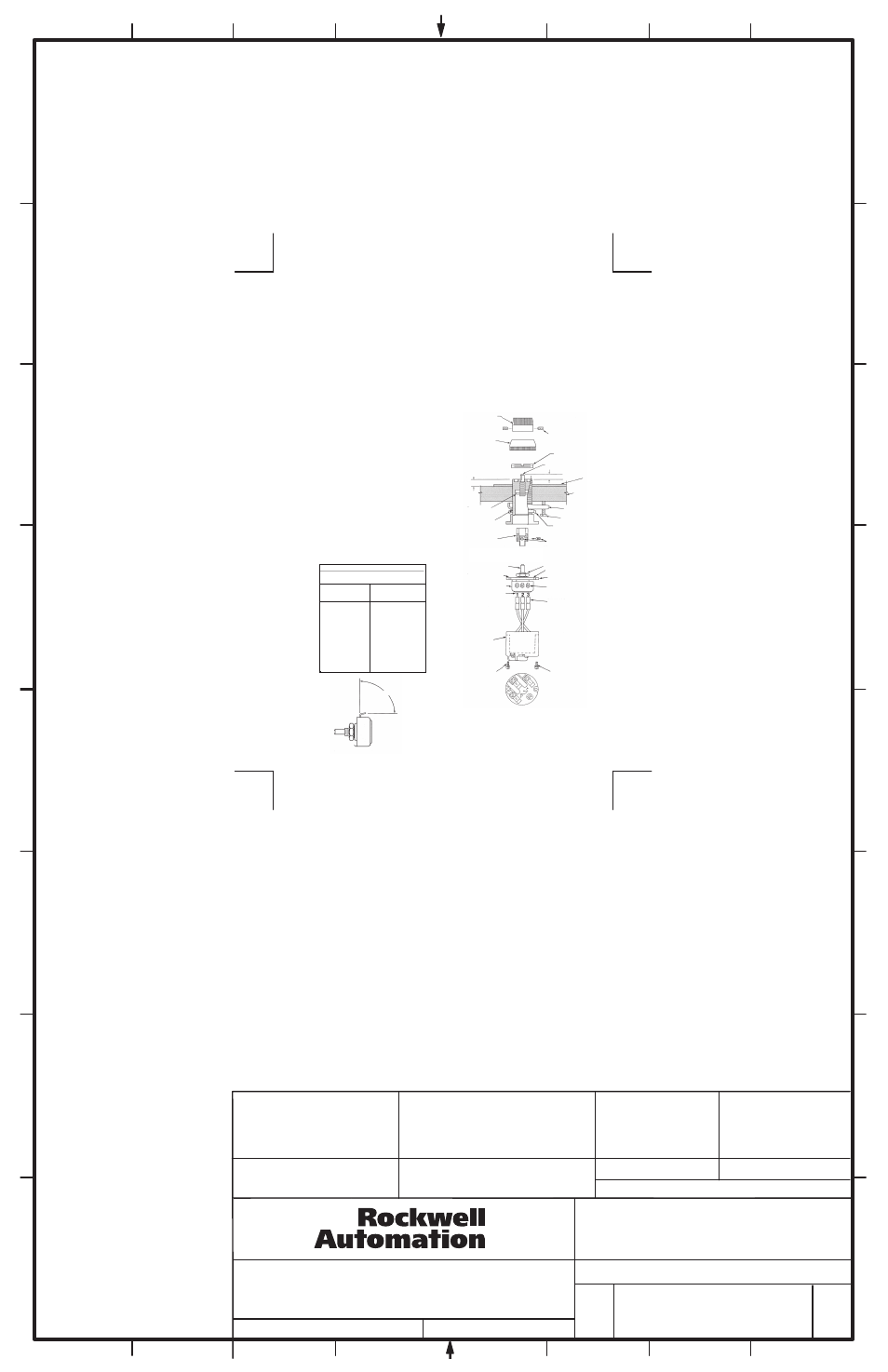

8. Rotate potentiometer clockwise to stop.

9. Place shaft adapter onto potentiometer shaft. Rotate shaft adapter to orient slot in shaft adapter with roll pin

in shaft while holes in diaphragm and mounting plate are in line with holes in mounting bushing.

10. Tighten the two set screws in the shaft adapter to 4 ± ½ lb.-in. with a 1/16" (1.6) hex wrench.

11. Line up holes in housing, mounting plate, and mounting bushing and push the unit into the mounting

bushing.

12. Secure by threading in the two screws from the rear of the potentiometer housing.

13. Rotate shaft counterclockwise to stop.

14. Position knob on shaft aligning white indexer on knob with "min." increment marking on legend plate.

15. Tighten the two set screws in the knob to 4 ± ½ lb.-in. with a 1/16" (1.6) hex wrench.

16. Install mounting ring and tighten. Allen-Bradley Catalog No. 800T-N3 wrench is available for this operation.

Enclosure must comply with U.L. standards 698 and 1203 and CSA standard C22.2 No. 30 for Class I

Groups B, C and D hazardous locations or C22.2 No. 25 for Class II Groups E, F and G hazardous locations.

For Class I locations, a suitable seal fitting is required within 18 inches.

Hole size to be .958 (24.3 Ø) to .970 diameter (24.6 Ø) ¾-14NPSM tap.

Apply grease from capsule (supplied) to threads of ¾-14NPSM hole before assembling units into panel and

to the threads of the lens assembly.

For standard length units (Bul. 800H), maximum panel

thickness is 1” (25.4). From 3/4” (9.5) to 23/32” (18.3)

securing ring is used as shown, without adjusting nut.

Securing ring is reversed when panel thickness is from

23/32” (18.3) to 29/32” (23) and eliminated between 29/32”

(23) and 1” (25.4).

For long barrel units (Bul. 800H), maximum panel thicknes

i s 2 1 / 2 ” ( 6 3 . 5 ) . F o r p a n e l s a b o v e 2 ” ( 5 0 . 8 ) b u t n o t

exceeding 21/2” (63.5) remove and discard securing ring

and tighten device with adjusting nut only.

For Class I Group B application, 5/8" (15.9) minimum

panel thickness is required.

Power Rating:

Maximum power (P) = 2 watts provided maximum working

voltage is not exceeded.

Maximum working voltage (EMAX) shall not exceed 300

volts (RMS or DC) or as determined by EMAX=

�PR, R =

resistance, whichever is less. See Table 1 for power

KNOB

ROLL PIN

MOUNTING

BUSHING

SHAFT ADAPTER

DIAPHRAGM

LOCATING TAB

POTENTIOMETER

TERMINAL

IDENTIFICATION

HOUSING

MOUNTING

SCREW

POTENTIOMETER SHAFT

SET SCREWS

1/16" (1.6) HEX WRENCH

TIGHTEN TO 4 ± 1/2 LB-IN

11/32 (8.7) IF

LEGEND PLATE

IS TO BE USED

9/32 (7.1) IF

LEGEND PLATE

IS NOT TO BE USED

SET SCREWS

1/16" (1.6) HEX WRENCH

TIGHTEN TO 4 ± 1/2 LB-IN

SHAFT

MOUNTING RING

ADAPTER

MOUNTING

RING

LEGEND

PLATE

LOCKING SCREW

ADJUSTING NUT

NUT AND LOCKWASHER

PRINTED SIDE

MOUNTING PLATE

POTENTIOMETER

TERMINAL

WIRE LEAD

MOUNTING

SCREW

NOTE:

WIRE RANGE:

18-14 AWG (0.5-2.5mm2)

TIGHTENING TORQUE:

6-7lb.in (0.7-0.8 Nm)

ENCLOSURE

SECURING RING

40 ± .01 (10.2 ± 2)

Table 1

Power derating with respect to rotation

for rheostat application

Percent

Rotation

Multiplying

Wattage

Rating By

100

1.00

90

.99

80

.98

70

.96

60

.93

50

.89

40

.81

30

.68

20

.49

10

.23

0

.11

80° - 90°

Figure 2

Figure 3

MATERIAL

NO.

MATERIAL

SIZE

FOLD

FLAT

4-1/4" W x 6-1/4" H 4-1/4" W x 3-1/8" H

TWO SIDES PRINTED

BODY STOCK WHITE

BODY INK BLACK

40060-303-01

B-vertical.ai

1

2

3

4

5

6

7

8

A

B

C

D

E

F

G

H

CONFIDENTIAL AND PROPRIETARY INFORMATION. THIS DOCUMENT

CONTAINS CONFIDENTIAL AND PROPRIETARY INFORMATION OF

ROCKWELL AUTOMATION, INC. AND MAY NOT BE USED, COPIED OR

DISCLOSED TO OTHERS, EXCEPT WITH THE AUTHORIZED WRITTEN

PERMISSION OF ROCKWELL AUTOMATION, INC.

40060-303

Sheet

Size

Ver

Of

2

2

B

05

Dr.

Date

- - - - - - - -

- - - - - - - -

40060-303-01 Ver (05)

Printed in U.S.A

�

INSTALLATION INSTRUCTIONS 800HL-EMP POTENTIOMETER

FOR NEMA TYPE 7 [3/8" (9.5) TO 2-1/2" (50.8) PANELS]

AND TYPE 9 [7/32" (7.2) TO 2-1/2" (50.8) PANELS]