Rockwell Automation 800H Potentiometer User Manual

Sheet size ver of 2 1

INSTALLATION INSTRUCTIONS 800HL-EMP POTENTIOMETER

FOR NEMA TYPE 7 [3/8" (9.5) TO 2-1/2" (50.8) PANELS]

AND TYPE 9 [7/32" (7.2) TO 2-1/2" (50.8) PANELS]

�

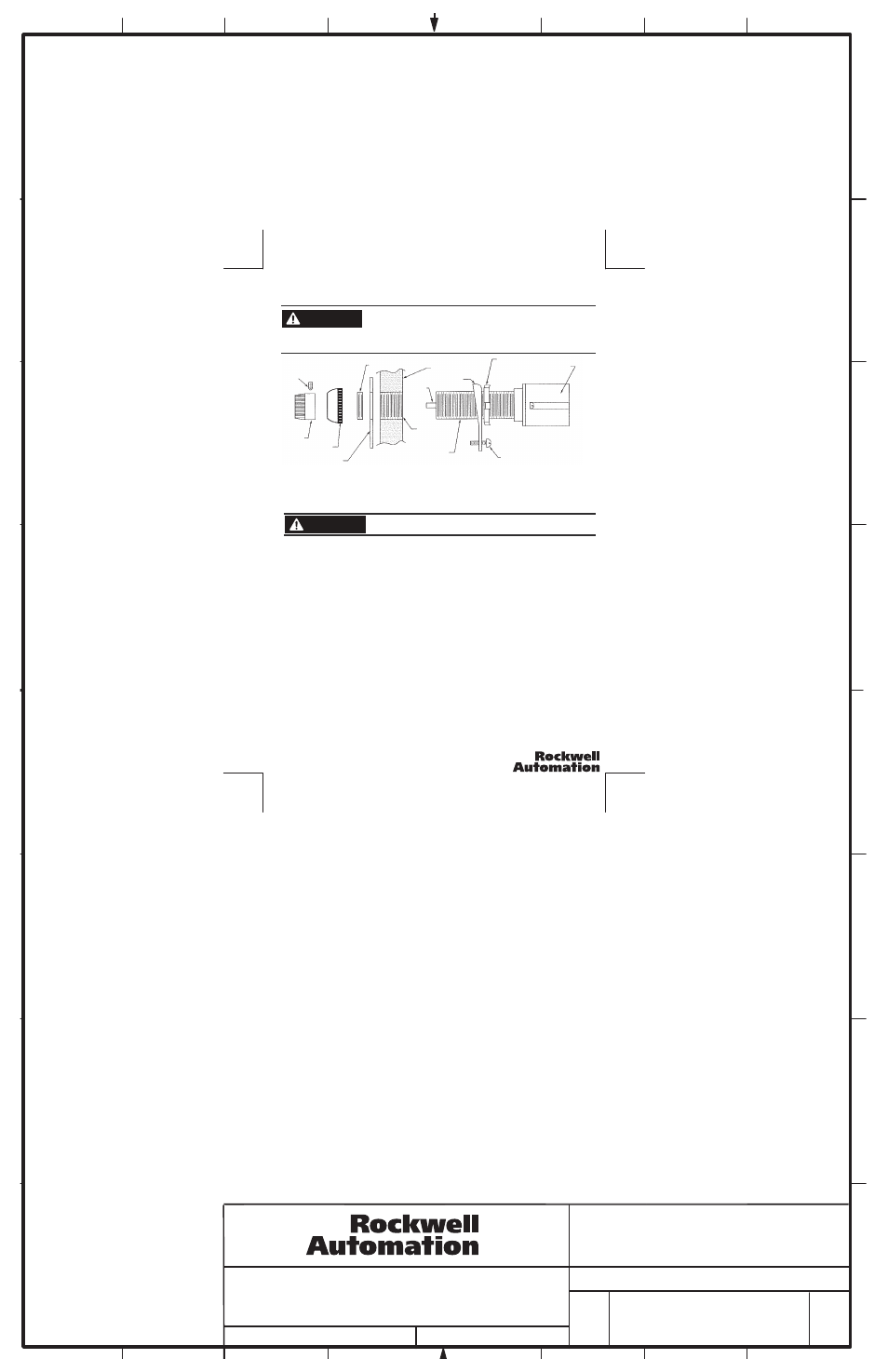

Installation: See Figure 1 for illustrated assembly.

1. Place securing ring and/or adjusting nut as supplied on unit and thread unit into panel until bushing extends

approximately 11/32" (8.7) [4 to 5 threads], past front of panel - 9/32" (7.1) [3 to 4 threads] if a legend plate is

not to be used, see Figure 3.

2. To secure unit, rotate to a position which provides electrical clearance and tighten adjusting nut and/or locking

screw. Where two units are mounted adjacently, arrange securing rings to avoid interference.

4. Place legend plate, if to be used, over mounting bushing.

5. Assemble mounting ring adapter and tighten.

6. Rotate shaft counterclockwise to stop.

7. Position knob on shaft aligning white indexer on knob with "min." increment marking on legend plate.

8. Tighten the two set screws in the knob to 4 ± ½ lb.-in. with a 1/16" (1.6) hex wrench.

9. Install mounting ring and tighten. Allen-Bradley Catalog No. 800T-N3 wrench is available for this operation.

Replacing Potentiometer: See Figure 3 for illustrated assembly.

NOTE 1: Refer to nameplate on housing for original potentiometer resistance.

NOTE 2: Unit need not be removed from enclosure to replace potentiometer.Potentiometer Removal:

1. Remove the two screws on the rear of the housing and pull the housing (see Figure 3) from the bushing.

2. Disconnect the three wire leads from the potentiometer terminals.

3. Loosen the two set screws in the shaft adapter with a 1/16" (1.6) hex wrench and remove shaft adapter from

potentiometer shaft.

4. Remove nut, lockwasher and mounting plate.

Potentiometer Installation:

1. Remove mounting ring leaving mounting ring adapter in place. Allen-Bradley Catalog No. 800T-N3 wrench is

available for this operation.

2. Loosen the two set screws in the knob with a 1/16" (1.6) hex wrench and remove knob.

3. Rotate shaft so that it extends .40 ± .01 (10.2 ± .2) from bushing.

4. Before installing potentiometer bend the three terminals 80° -90° and remove nut and lockwasher from

bushing (see Figure 2).

5. Install mounting plate, printed side facing outward, over potentiometer shaft aligning locating tab on

potentiometer with slot in mounting plate.

6. Tighten nut and lockwasher on potentiometer shaft and bend locating tab to fit mounting plate.

7. Insert wire leads onto the potentiometer terminals making sure the leads identified as 1, 2 and 3 are attached

to the correspondingly identified potentiometer terminals. (See Figure 3 for terminal identification.) If the

potentiometer housing does not have wires with terminal lugs, cut and strip the wires and solder the wire end

to the appropriate potentiometer terminal.

KNOB

MOUNTING RING

LEGEND PLATE

SET SCREWS

1/16" (1.6) HEX WRENCH

TIGHTEN TO 4 ± 1/2 LB-IN

PANEL

ADJUSTING NUT

LOCKING SCREW

HOUSING

SECURING RING

MOUNTING BUSHING

SHAFT

ADAPTER RING

Figure 1

B-vertical.ai

1

2

3

4

5

6

7

8

CONFIDENTIAL AND PROPRIETARY INFORMATION. THIS DOCUMENT

CONTAINS CONFIDENTIAL AND PROPRIETARY INFORMATION OF

ROCKWELL AUTOMATION, INC. AND MAY NOT BE USED, COPIED OR

DISCLOSED TO OTHERS, EXCEPT WITH THE AUTHORIZED WRITTEN

PERMISSION OF ROCKWELL AUTOMATION, INC.

40060-303

Sheet

Size

Ver

Of

2

1

B

05

Dr.

Date

M. Guelmi

04-25-12

� � �

� �

To avoid damage to equipment or injury to personnel, electrical power

must be off before and during installation and maintenance.

M a i n t a i n ½ " ( 1 2 . 7 ) m i n i m u m c l e a r a n c e t h r o u g h a i r b e t w e e n

current-carrying parts and enclosure.

When Installing in a metal enclosure, maintain 1/2” (12.7) minimum

clearance through air between current carrying parts enclosure.

WARNING

WARNING

3.

WARNING

WARNING

WARNING

40060-303-01 Ver (05)

Printed in U.S.A

�

INSTALLATION INSTRUCTIONS 800HL-EMP POTENTIOMETER

FOR NEMA TYPE 7 [3/8" (9.5) TO 2-1/2" (50.8) PANELS]

AND TYPE 9 [7/32" (7.2) TO 2-1/2" (50.8) PANELS]