Setting the analog output: q2 – Rockwell Automation 45LMS Laser Measurement Sensor User Manual

Page 4

Power, Control and Information Solutions Headquarters

Americas: Rockwell Automation, 1201 South Second Street, Milwaukee, WI 53204-2496 USA, Tel: (1) 414.382.2000, Fax: (1) 414.382.4444

Europe/Middle East/Africa: Rockwell Automation NV, Pegasus Park, De Kleetlaan 12a, 1831 Diegem, Belgium, Tel: (32) 2 663 0600, Fax: (32) 2 663 0640

Asia Pacific: Rockwell Automation, Level 14, Core F, Cyberport 3, 100 Cyberport Road, Hong Kong, Tel: (852) 2887 4788, Fax: (852) 2508 1846

www.rockwel lautomation.com

10000237459 Ver 00 Copyright ©2012 Rockwell Automation, Inc. All Rights Reserved.

March 2012

After the LED

s

fl

as

h

s

im

u

lt

a

neo

us

ly, they fl

as

h

a

ltern

a

tely to

indic

a

te whether the Te

a

ch w

as

su

cce

ss

f

u

l:

Su

cce

ss

f

u

l:

s

lower

a

ltern

a

ting fl

as

hing (2.5 Hz)

Un

su

cce

ss

f

u

l: f

as

ter

a

ltern

a

ting fl

as

hing (

8

Hz).

¹

3. Place a target at the farther (relative to the sensor) desired

Teach-point, move the Rotary Switch to position Q1-A

(Q1-B for NPN).

4. Press and hold the SET button until the Green and Yellow

LEDs flash simultaneously

1

.

5. If the Teach is successful, move the Rotary Switch to RUN.

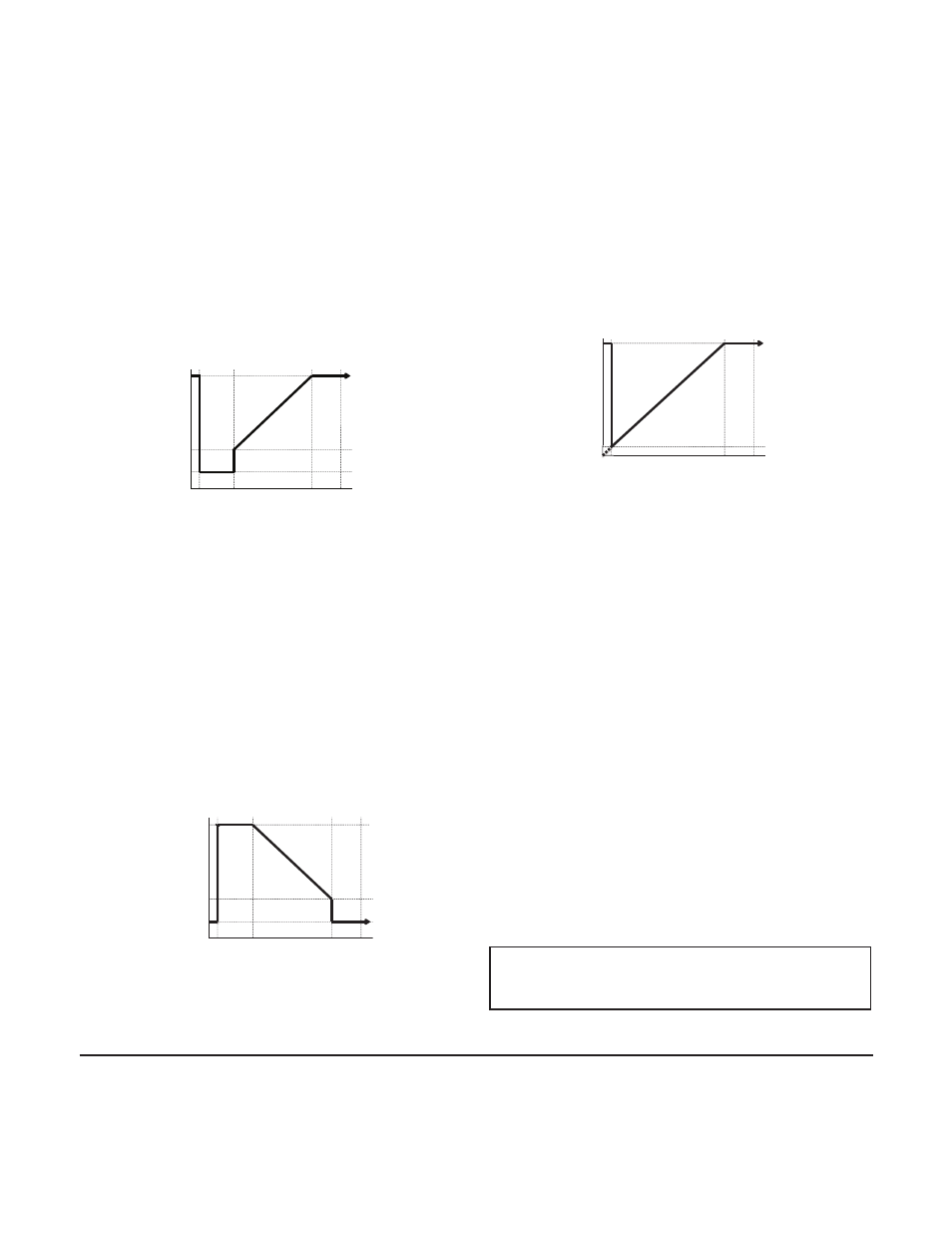

Setting the analog output: Q2

The 4…20 mA output can be defined as any range within 200 mm

to the maximum range of the sensor, as either a rising or falling

slope, as described below. The default analog output setting for

Q2 is A = 200 mm (8 in.) and B = 5,000 mm (16 ft) for all sensor

models. Minimum window for setting the analog span is 21 mm

(0.83 in.)

Positive Slope

In the Positive Slope mode (also called Rising Slope) a target

positioned at the closer set-point results in an analog output of

4 mA while a target at the farther set-point results in an output of

20 mA, with the analog output scaled linearly in between. In this

mode, the sensor will output 20 mA when the target is outside of

the operating range, which is 0…200 mm (0…8 in.) and anything

greater than the maximum sensing range.

1. Place a target at the minimum Teach-point.

2. Move the Rotary Switch to position Q2-A.

3. Press and hold the SET button until the Green and Yellow

LEDs flash simultaneously

1

.

4. Place a target at the maximum Teach-point.

5. Move the Rotary Switch to position Q2-B.

6. Press and hold the SET button until the Green and Yellow

LEDs flash simultaneously

1

.

7. If the Teach is successful, move the Rotary Switch to RUN.

Negative Slope

In the Negative Slope mode (also called Falling Slope) a target

positioned at the farther set-point results in an analog output of

4 mA while a target at the closer set-point results in an output of

20 mA

4 mA

~3

.9 mA

0.2 m Q2A

MAX

Q2B

20 mA

4 mA

~3

.9 mA

0.2 m Q2B

MAX

Q2A

20 mA, with the analog output scaled linearly in between. In this

mode, the sensor will output 3.9 mA when the target is outside of

the operating range, which is 0…200 mm (0…8 in.) and anything

greater than the maximum sensing range.

1. Place a target at the maximum Teach-point, and move the

Rotary Switch to position Q2-A.

2. Press and hold the SET button until the Green and Yellow

LEDs flash simultaneously

1

.

3. Place a target at the minimum Teach-point, move the Rotary

Switch to position Q2-B.

4. Press and hold the SET button until the Green and Yellow

LEDs flash simultaneously

1

.

5. If the Teach is successful, move the Rotary Switch to RUN.

Zero Point (Positive Slope)

In the Zero Point (Positive Slope) mode a target positioned at the

farther set-point (Q2-B) results in an analog output of 20 mA and

the analog signal is scaled linearly between 0.0 mm and (Q2-B).

This is useful for simplifying the scaling within the PLC or control

device. For example, the following equation can be used:

D = (D

Max

/ I

Max

)

*

I

i

where

D = Current distance of target

D

Max

= set-point distance

I

Max

= analog range (which is always 20 for the 45LMS)

I

i

= current analog output from sensor.

However, even though the analog signal is scaled linearly from

0.0 mm to (Q2-B) it will still provide an analog output of 20 mA

when the target is outside of the operating range, which is

0…200 mm (0…8 in.) and anything greater than the maximum

sensing range. (This is due to the fact that the 45LMS cannot

detect objects between 0…200 mm.)

1. Place a target at the maximum Teach-point.

2. Move the Rotary Switch to position Q2-B.

3. Press and hold the SET button until the Green and Yellow

LEDs flash simultaneously

1

.

4. Move the Rotary Switch to position Q2-A, and delete the set-

point [factory default is 200 mm (8 in.)] by pressing and holding

the SET button for >5 s. Successful completion is indicated by

both LEDs turning off.

5. If the Teach is successful, move the Rotary Switch to RUN.

20 mA

<

3

.9 mA

<0.2 m

MAX

Q2B

0 2