Calibrating the nozzle height – Afinia H480 3D Users Manual User Manual

Page 16

Afinia H480 3D Printer User’s Manual

16

The adjustments in the example shown, for instance, indicate that the print surface is warped, with

the center higher than both the front and back edges. Using the Platform Level Calibration utility,

you can correct for this warping.

This process is not intended to replace manually leveling the platform. It should only be

used if your print surface itself cannot be leveled due to warping or an inconsistent

thickness.

Calibrating the Nozzle Height

This section is probably the most important of the entire manual. Please read it carefully to

ensure that you understand the nozzle height setup procedure, as it is vital to successful

3D printing.

To print successfully, the platform should be set to start at a distance of 0.2mm from the nozzle. As

each printer is slightly different, this distance needs to be calibrated before starting to print.

Like with the automatic Platform Level Calibration, you can set the nozzle height either

automatically or manually.

If you are using any print surface other than the supplied FR-4 (Perf) Board, you will need to

set the Nozzle Height manually!

Automatic Nozzle Height Calibration

The Automatic Nozzle Height Calibration process assumes that you are using the supplied FR-4

perf board as the print surface. If you are using any other surface, or the perf board with

BuildTak or any other surface adhered to the board, you must manually determine the

nozzle height.

To determine the correct nozzle distance using the automated process, please follow these steps:

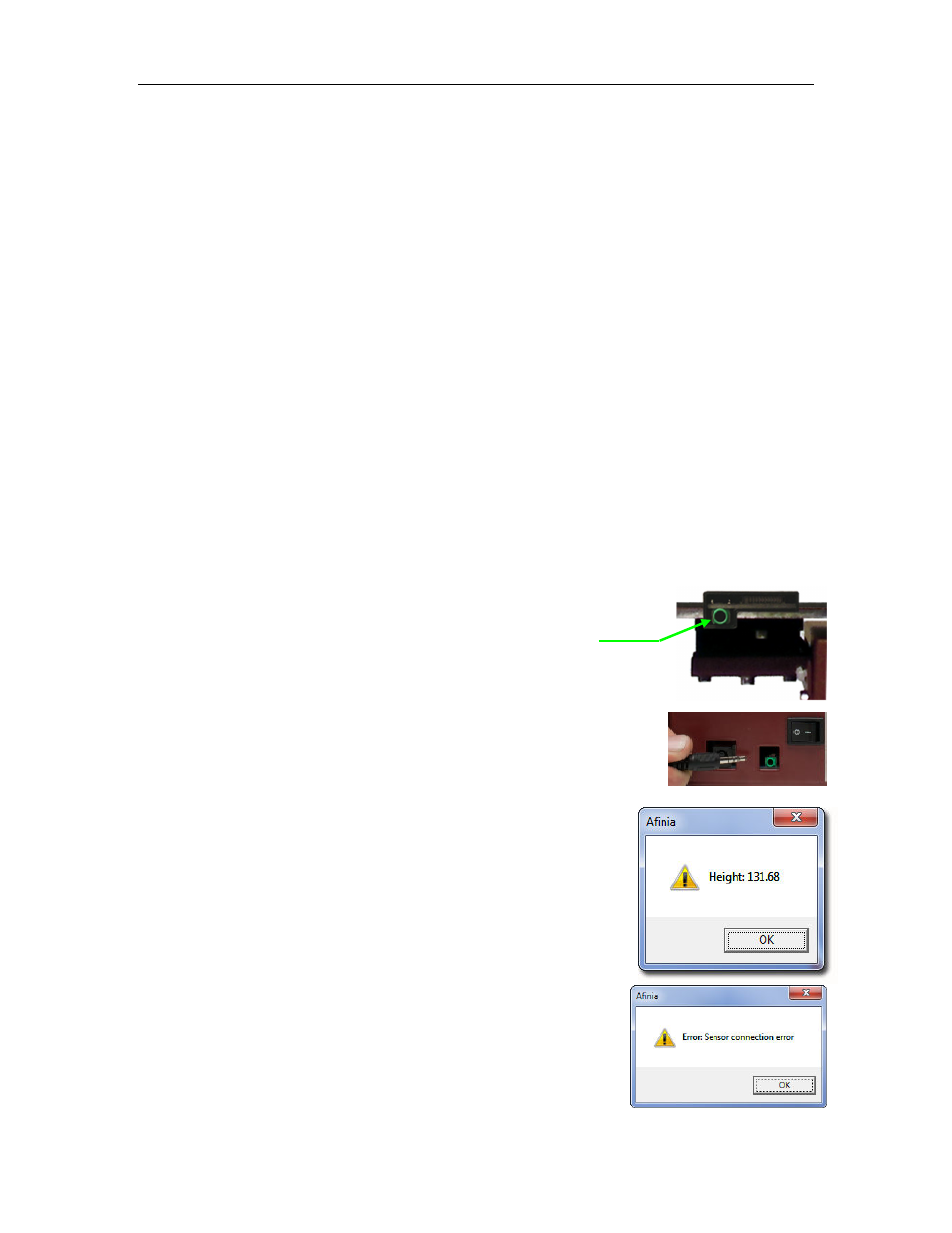

1. Connect the data cable to the Nozzle Sensor, located on the back of

the print platform. The cable plugs into the data connector.

2. Connect the data cable to the green Data Connection on the back of

the printer.

3. Select Nozzle Height Detect from the 3D Print menu.

4. The extruder will move to the center of the printer and the

platform will move forward before the platform lifts. As it nears

the top of the printer, the platform will slow until the nozzle

contacts the Nozzle Sensor. The detected nozzle height will be

displayed, and the platform will lower.

5. After the Nozzle Height Calibration is complete, remove the data

cable from the Nozzle Sensor and from the data connection on

the back of the printer.

If the message to the right appears when you choose the Nozzle

Height Detect option, check that the data cable is securely

connected to both the Nozzle Sensor and the data connection on the

back of the printer. After verifying the connections, select Nozzle

Height Detect again.