Installation, Gas pipe pressure testing, Aeration adjustment – Regency Hampton H35 Large Gas Stove User Manual

Page 29

Hampton® H35-2 Direct Vent Freestanding Gas Stove

29

INSTALLATION

GAS PIPE

PRESSURE TESTING

The appliance must be isolated from the gas sup-

ply piping system by closing its individual manual

shut-off valve during any pressure testing of the

gas supply piping system at test pressures equal

to or less than 1/2 psig. (3.45 kPa). Disconnect

piping from valve at pressures over 1/2 psig.

The manifold pressure is controlled by a regulator

built into the gas control, and should be checked

at the pressure test point.

Note: To properly check gas pressure, both

inlet and manifold pressures should be

checked using the valve pressure ports

on the valve.

1) Make sure the valve is in the "OFF" position.

2) Loosen the "IN" and/or "OUT" pressure tap(s),

turning counterclockwise with a 1/8" wide fl at

screwdriver.

3) Attach manometer to "IN" and/or "OUT" pres-

sure tap(s) using a 5/16" ID hose.

4) Light the pilot and turn the valve to "ON" posi-

tion. Read manometer.

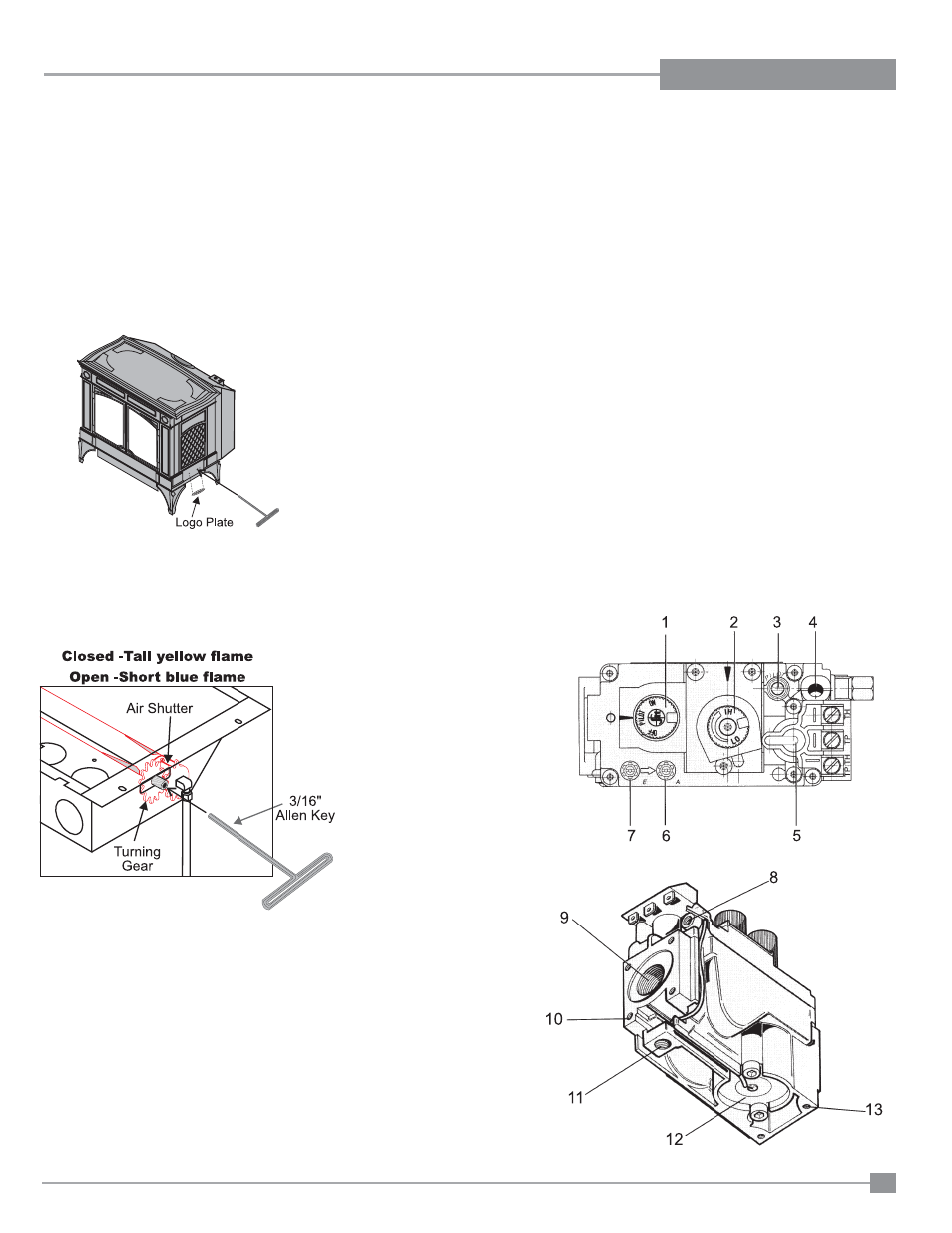

To adjust the aeration: use the allen key to turn

the turning gear which will adjust the air shutter.

Open the air shutter for a blue fl ame or close it for

a yellower fl ame.

Caution: Carbon will be produced if the air shut-

ter is closed too much.

Note: Any damage due to carboning resulting

from improperly setting the aeration

controls is NOT covered under warranty.

Note: Aeration Adjustment should only be

performed by an authorized Hampton

®

Installer at the time of installation or

service.

5) The pressure check should be carried out

with the unit burning and the setting should

be within the limits specifi ed on the safety

label.

6) When fi nished reading manometer, turn

off the gas valve, disconnect the hose and

tighten the screw (clockwise) with a 1/8" fl at

screwdriver. Note: Screw should be snug,

but not over tightened.

Valve Description

1) Gas on/off knob

2) Manual high/low adjustment

3) Pilot

Adjustment

4) Thermocouple

Connection

5) Main

Operator

6) Outlet Pressure Tap (Manifold Pressure)

7) Inlet Pressure Tap (Supply Pressure)

8) Pilot

Outlet

9) Main Gas Outlet

10) Flange Securing Screw Holes

11) Alternative TC Connection Point

12) Thermoelectric Unit

13) Additional Valve Mounting Hole

AERATION

ADJUSTMENT

The burner aeration is factory set but may need ad-

justing due to either the local gas supply, air supply

or altitude.

Natural Gas

1/4" (6.4 mm)

Propane

3/8" (9.5 mm)

The aeration adjustment gears are located on the

right side of the burner box. Remove the Hampton

®

Logo plate on the right side of the unit to access the

adjustment gears.

Clockwise to open,

counter-clockwise to close.