Installation, Horizontal installations, Rigid vent system – Regency Hampton H35 Large Gas Stove User Manual

Page 24

24

Hampton® H35-2 Direct Vent Freestanding Gas Stove

INSTALLATION

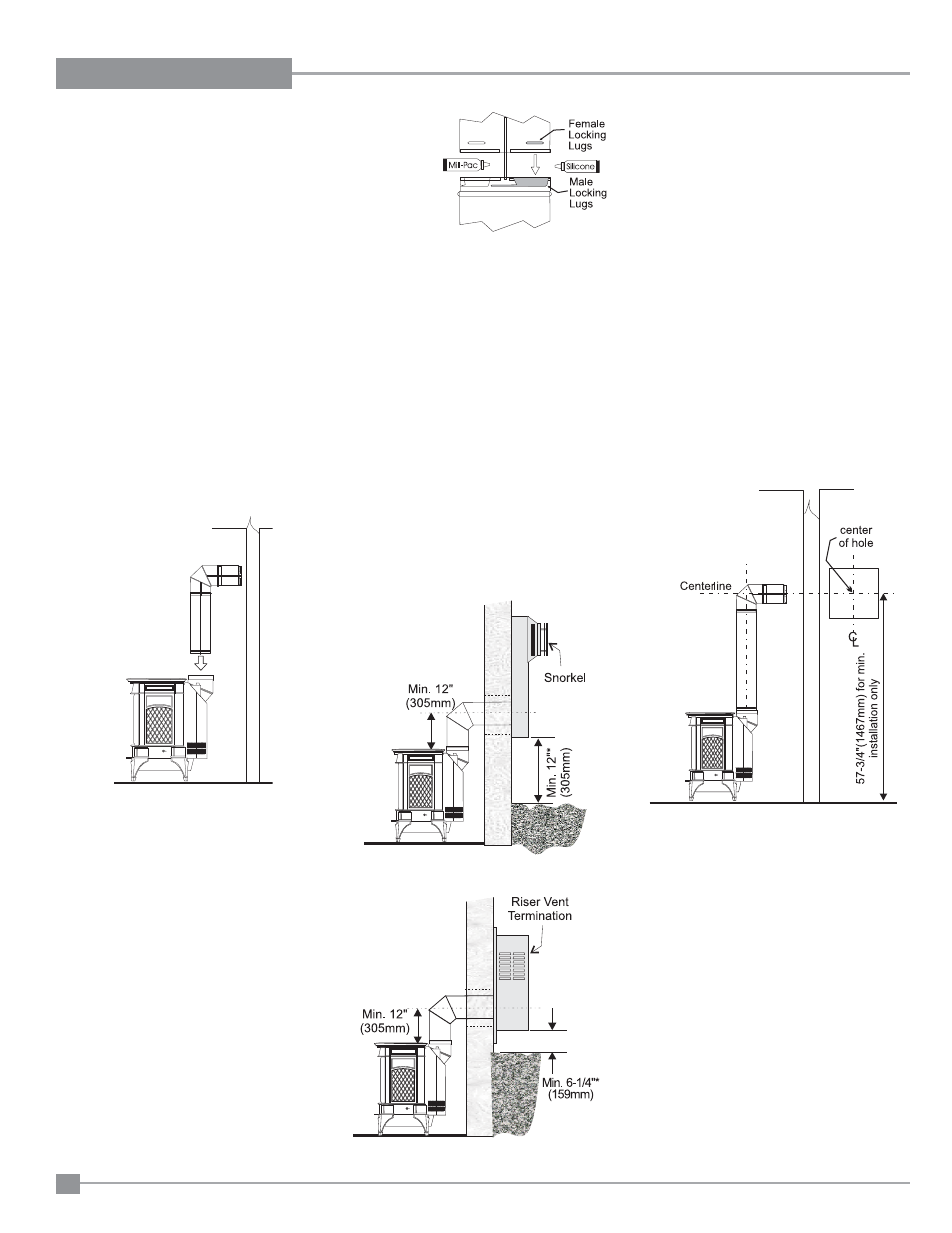

Diagram 2a

Diagram 3

Below Grade Snorkel Installation

If the Snorkel Termination must be installed

below grade, i.e. basement application, proper

drainage must be provided to prevent water

from entering the Snorkel Termination. Refer to

Vent Manufacturer Installation instructions for

details. Do not attempt to enclose the Snorkel

within the wall, or any other type of enclosure.

3) With the pipe attached to the stove, slide the

stove into its correct location, and mark the

wall for a 10" x 10" (inside dimensions) square

hole. The center of the square hole should line

up with the center line of the horizontal pipe, as

shown in diagram 3. Cut and frame the 10 inch

square hole in the exterior wall where the vent

will be terminated. If the wall being penetrated

is constructed of non-combustible material, i.e.

masonry block or concrete, a 7" diameter hole

is acceptable.

*As specifi ed in CAN/

CSA B149.1 Installation

Code. Local codes or

regulations may require

different clearances.

Diagram 2

Diagram 1:

Hint: Apply

silicone to

female end.

HORIZONTAL

INSTALLATIONS

RIGID VENT SYSTEM

1) Set the unit in its desired location. Check to

determine if wall studs or roof rafters are in

the way when the venting system is attached.

If this is the case, you may want to adjust the

location of the unit.

2) Direct Vent pipe and fi ttings are designed with

special twist-lock connections to connect the

venting system to the appliance fl ue outlet.

A twist-lock appliance adaptor is installed on

the unit at the factory. Assemble the desired

combination of pipe and elbows to the appliance

adaptor with pipe seams oriented towards the

wall or ceiling, as much out of view as pos-

sible. The fi nal positioning of the pipe and 90

o

elbow assembly is determined by the mounting

orientation of the adaptor on the stove and

twist-locked for a solid connection.

b) Horizontal runs of vent must be sup-

ported every three feet. Wall straps are

available for this purpose.

c) Snorkel Terminations:

For installations requiring a vertical rise

on the exterior of the building, 14-inch

and 36-inch tall Snorkel Terminations

and the Riser Vent as shown in Diagrams

2 & 2a are available. Follow the same

installation procedures as used for stand-

ard Horizontal Termination. NEVER

install the snorkel upside down.

Note:

a) Twist-lock procedure: Four indentations,

located on the female ends of pipes and

fi ttings, are designed to slide straight onto

the male ends of adjacent pipes and fi ttings,

by orienting the four pipe indentations so

they match and slide in to the four entry

slots on the male ends (Diagram 1). Push

the pipe sections completely together,

then twist-lock one section clockwise

approximately one-quarter turn, until the

two sections are fully locked. The female

locking lugs will not be visible from the

outside on the Black Pipe or fi ttings. They

may be located by examining the inside of

the female ends.

NOTE: For best results and optimum per-

formance with each approved venting

system, it is highly recommended to

apply “Mill-Pac” sealant (supplied) to

every inner pipe connection. Failure

to do so may result in drafting or

performance issues not covered

under warranty. Silicone (red RTV)

is optional.