Schwank SEB(U) User Manual

Page 7

SP-MSEB-BX-10A

SEB Manual

RD: JUNE 2004

RL: 10

KH

Page 3

4. PRE-INSTALLATION SURVEY

The Schwank SEB /SEBU heating system

must have gas piping of the correct diameter,

length, and arrangement to function properly.

For this reason, a layout drawing is

necessary.

Carefully survey area to be heated, and for

best results, whenever possible, place burner

and combustion chamber in coldest area.

5. MOUNTING CLEARANCES

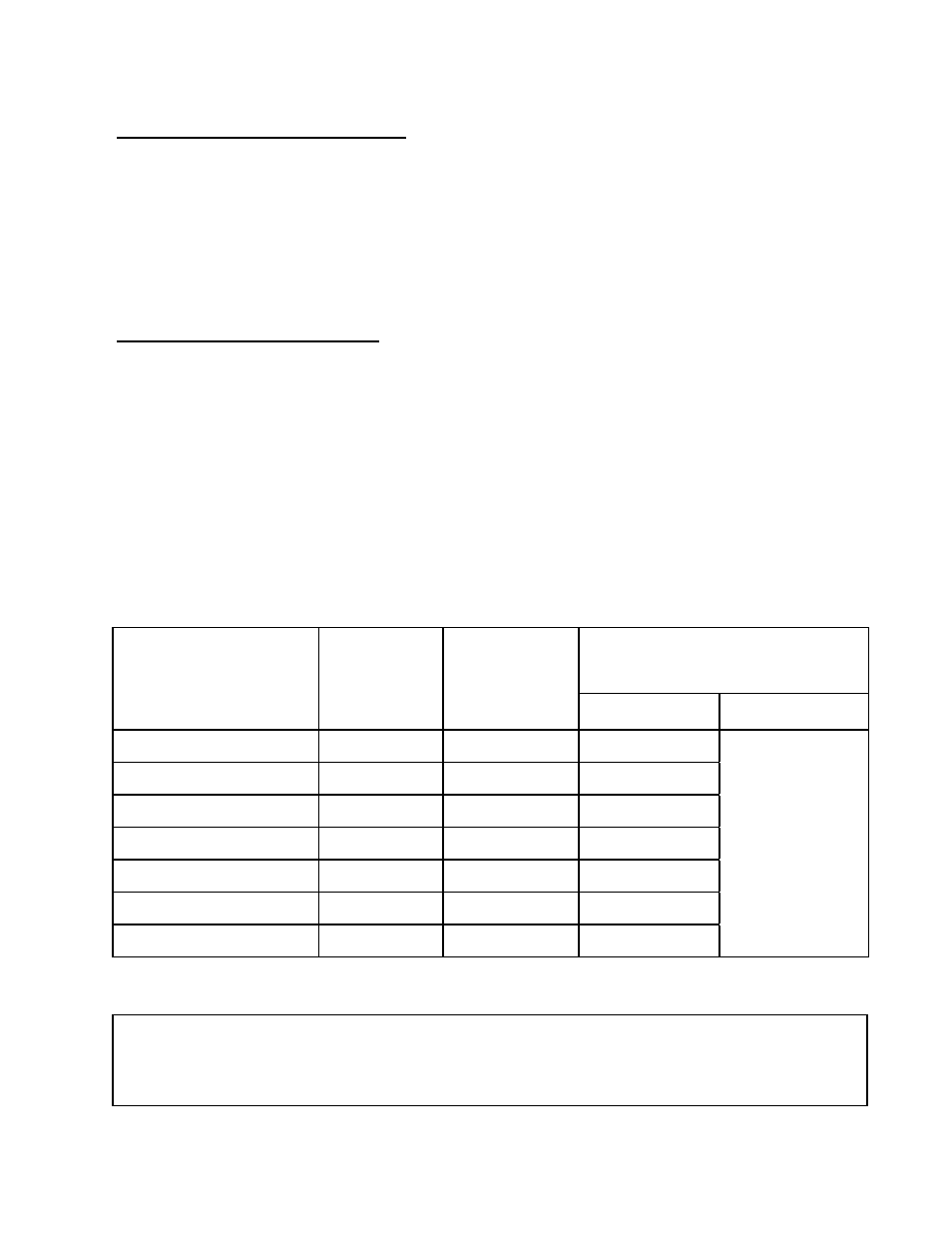

TABLE 2: RECOMMENDED HEATER PLACEMENT

MODEL

MOUNTING

HEIGHTS

(FEET)

MAXIMUM

DISTANCE

BETWEEN

HEATERS

(FEET)

DISTANCE-OUTSIDE WALL

TO HEATER LONG AXIS

PARALLEL TO WALL (FEET)

HORIZONTAL

ANGLE

SEB/U 200

18 – 25

50

17 – 25

SEB/U 175

18 – 25

50

17 – 25

SEB/U 155

16 – 21

45

15 – 20

SEB/U 130

15 – 21

40

15 – 20

SEB/U 110

13 – 19

35

13 – 18

SEB/U 80

10 – 16

30

12 – 16

SEB/U 60

8 – 14

25

11 – 15

COMBUSTIBLE

CLEARANCE

IMPORTANT: Continuous operation of single or multi-heater placement must

not cause any combustible material in storage to reach a

temperature in excess of 160

O

F.

This heater must be mounted and positioned

to maintain the minimum clearance to com-

bustible materials as shown in FIGURE 1

(PAGE 4) TABLE 3 (PAGE 4). For recom-

mended heater placement refer to TABLE 2

(below). Heaters should also be located and

installed with respect to building construction

and equipment to provide a minimum clear-

ance of 24 inches from the end of burner

housing for servicing and cleaning of burner,

blower and controls. A minimum horizontal

clearance of 4 ft. from electrical meters, gas

meters, regulators and relief equipment is re-

quired by ANSI Z223.1.& CSA B149.1-00.