Schwank SEB(U) User Manual

Page 10

SP-MSEB-BX-10A

SEB Manual

RD: JUNE 2004

RL: 10

KH

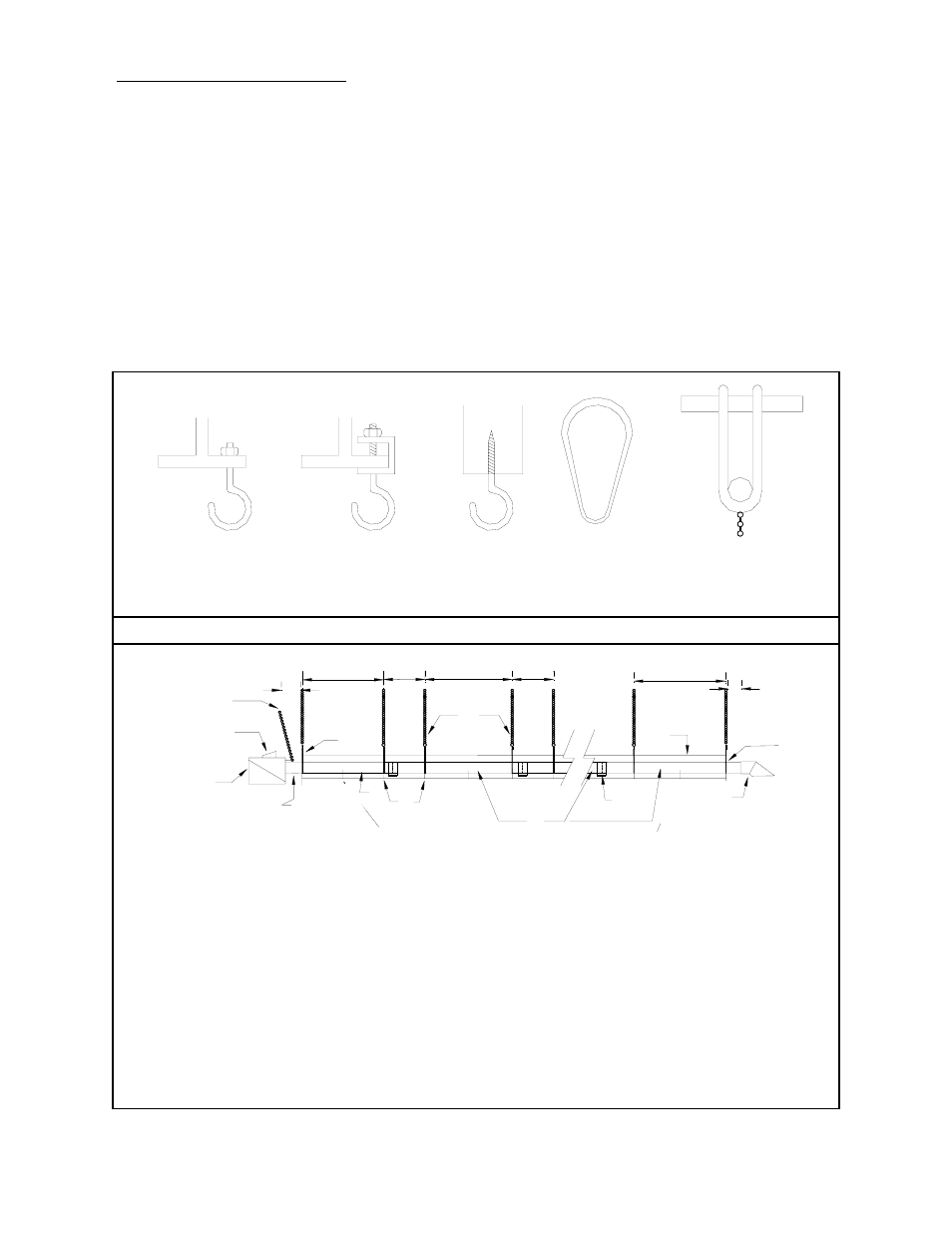

7. SUSPENSION SYSTEM

The system configuration and available

support locations must be considered in order

to locate the radiant tubes correctly. Labour

and material can be reduced by locating

(system configuration permitting) directly

under structural members such as joists, steel

or wood beams, etc.

Chain is recommended for hanging the tube

system, connecting the hangers to beam

support as illustrated in FIGURE 3 (below).

To support burner and keep it level, a

separate suspension chain must be attached

to the eye hook at flange end of burner angled

slightly back over burner, FIGURE 4

(below). This will permit normal expansion

and contraction of the tube system. (If rigid

devices such as rods are used in place of

chain, swing joints or other means of

sufficient length must be provided to

compensate for expansion.)

FIGURE 4: SEB TYPICAL HANGER & SUPPORT SPACING

Page 6

FIGURE 3: SUGGESTED MOUNTING HARDWARE

EYE BOLT THROUGH

HOLE IN BEAM

BEAM CLAMP

WITH EYE SCREW

EYE

SCREW

PIPE RING

OR CLEVIS

BAR-JOIST

CLAMP

* Distances shown are recommendations and may be varied to match field requirements.

1 Heater Support Chain

2 Burner Assembly

3 Igniter / Sensor

4 Focus Shield Reflector

5 Aluminized Tube with Flange

6 Tube Coupler

7 Steel Tube

8 Flue Vent terminal

9 Burner Support Chain

10 Wall Vent Terminal

11 Suspension Hanger

12 Gas Line

ALL TUBES MUST BE SUSPENDED BY TWO (2) HANGERS PER 10’ LENGTH, MOUNTED APPROXIMATELY 6” TO 12”

IN FROM EACH TUBE END.

10

13

2

11

4

3

5

6

8

7

9

1

1

12

3"

4"

"ALL TUBES MUST BE SUSPENDED BY TWO (2) HANGERS PER 10' LENGTH,

MOUNTED APPROXIMATELY 6" TO 12" IN FROM EACH TUBE END.