S&S Cycle Serial Delphi Style VFI (Variable Fuel Injection) Module and ProTune II Software User Manual

Page 9

9

BASIC COMMUNICATION TROUBLESHOOTING

1- Verify you are using the serial communication cable supplied with the VFI module. This cable will only have 3 of the 9 pins installed at the VFI

module (male) end of the cable. Use of a standard cable may cause damage to the PC.

2- Check that the VFI module is powered. The VFI module must be supplied with vehicle power in order to operate. Your motorcycle ignition and

run/stop switch should be set to the ON and RUN positions. Make sure that the battery voltage is normal. Try cycling power to the VFI module

(switch off the ignition for 15 seconds and then switch on).

3- Check that the cable is connected firmly to the VFI module and the PC.

4- If you are using a USB to serial converter, be sure that the converter you are using is compatible with your PC’s operating system. Also, be

sure that the driver software for the converter was installed per the manufacturer’s instructions. Please review the USB to Serial Converter

Information section of this instruction sheet for additional information.

5- Check the configuration of ProTune II for the correct COM port. See the section on Identifying COM Port of PC at the end of these

instructions.

PROTUNE II DIAGNOSTICS

The recommended method for checking the VFI module for Diagnostic Trouble Codes (DTCs) is by using the ProTune II software. This method will

provide a more complete list of DTCs than the Check Engine Lamp Diagnostics method listed below. DTCs can be read and cleared by clicking on the

DTCs button found on the upper left of the ProTune II screen when connected to a powered module.

Please, refer to the ProTune II manual or help files for more information on DTCs.

CHECK ENGINE LAMP DIAGNOSTICS

The S&S VFI module has a feature which can report engine faults by flashing a code via the Check Engine lamp on the motorcycle.

NOTE: If you have set your motorcycle to use the check engine lamp as a shift-light, this function will be disabled.

The procedures to activate and read the check engine lamp are as follows:

1. Turn the ignition switch to the ON position for three seconds (one second pause after the fuel pump stops), and then switch back to the OFF

position for three seconds. Repeat this procedure one more time and then turn the ignition to the ON position and wait for eight seconds for

the check engine lamp to start flashing.

2. The transmission of a code is always preceded by a series of rapid flashes (about 3 per second). This “intermission” is followed by a 2 second

pause in which the lamp is off. The lamp will then flash one or more times to indicate the first digit of the trouble code. The length of time the

lamp is illuminated and the length of time in which it is off are each about 1 second in duration. The number of times the lamp flashes indicated

the first digit of the trouble code.

3. Following the transmission of the first digit, there is another 2 second pause in which the lamp is off. The lamp will then flash one or more times

to indicate the second digit of the trouble code. The number of times the lamp flashes indicates the second digit of the trouble code.

4. Following the transmission of the second digit, there is a third 2 second pause in which the lamp is off. After the pause comes an “intermission”,

followed by transmission of the next recorded trouble code. All subsequent codes are sent in the same manner, each separated from the

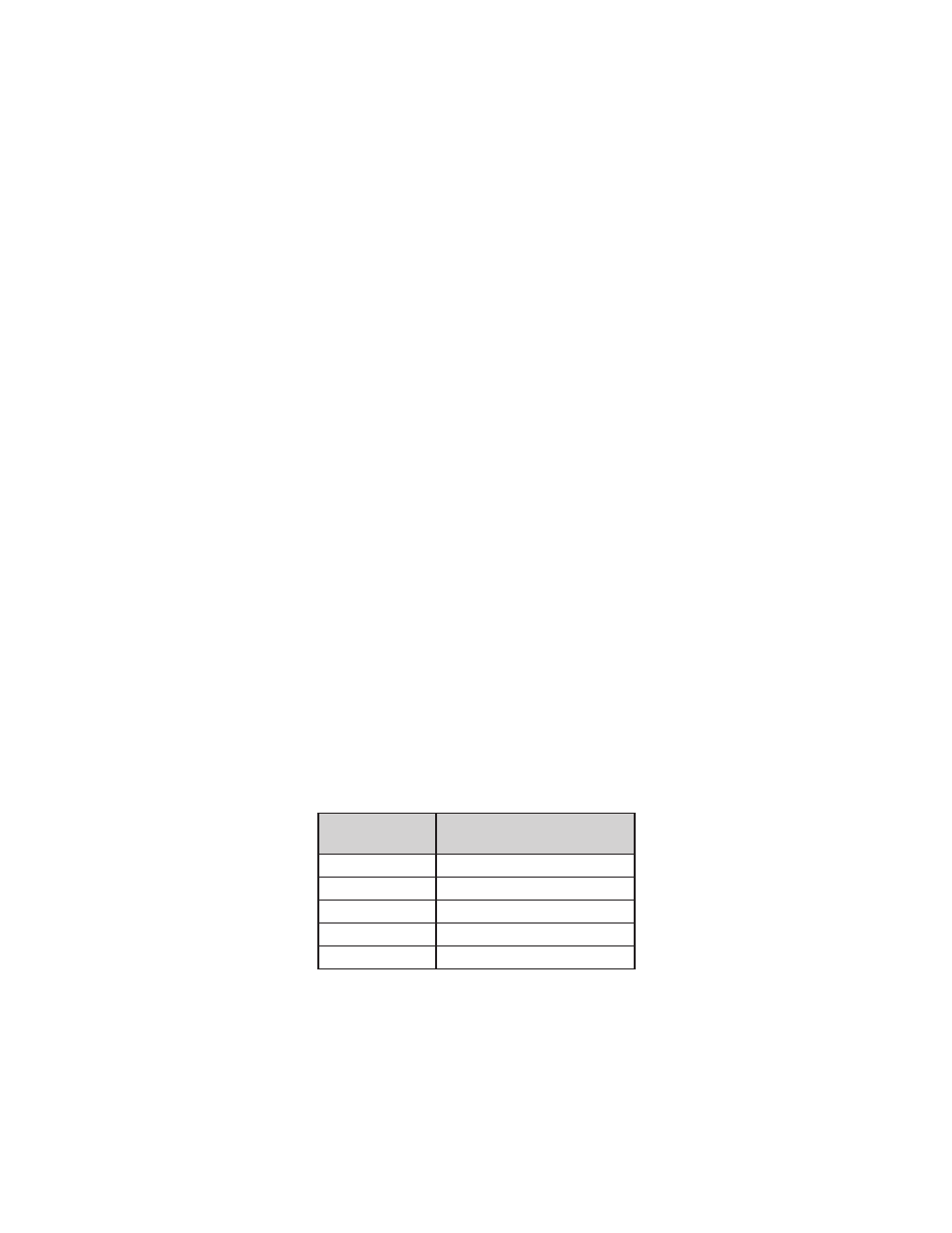

next by an “intermission”. Once all the trouble codes have been sent the data string is repeated. See table below for a list of the trouble codes

supported.

5. Turn the Ignition Key switch to OFF. Wait 10 seconds for the ECU relay to click. The vehicle can now be started normally.

Check Engine

Lamp Flash Code

Fault Condition

11

Throttle Position Sensor

12

Barometric Pressure Sensor

14

Engine Temperature Sensor

15

Intake Air Temperature Sensor

16

System Voltage (Battery) High