S&S Cycle Bore Big Twin Stroker Kit 1936–1999 3 7/16 - 3 1/2 User Manual

Page 4

4

1. Crankcase Alignment & Cylinder Mounting Studs (All)

NOTE: Some H-D® crankcase base gasket surfaces on which cylinders are positioned do not align properly. This usually occurs when crankcase halves

used are from different crankcase assemblies and were not paired and machined together at Harley-Davidson. It is recommended to check for crankcase

misalignment even if crankcase halves are correctly matched to prevent potential oil leaks and other mechanical problems.

Mismatched gasket surfaces due to improperly aligned crankcase halves may cause unwarranted stress on cylinder base flanges which

could result in cylinder flange failure.

A. Clean cases thoroughly and assemble both cases without flywheels and tighten all case bolts as in final assembly.

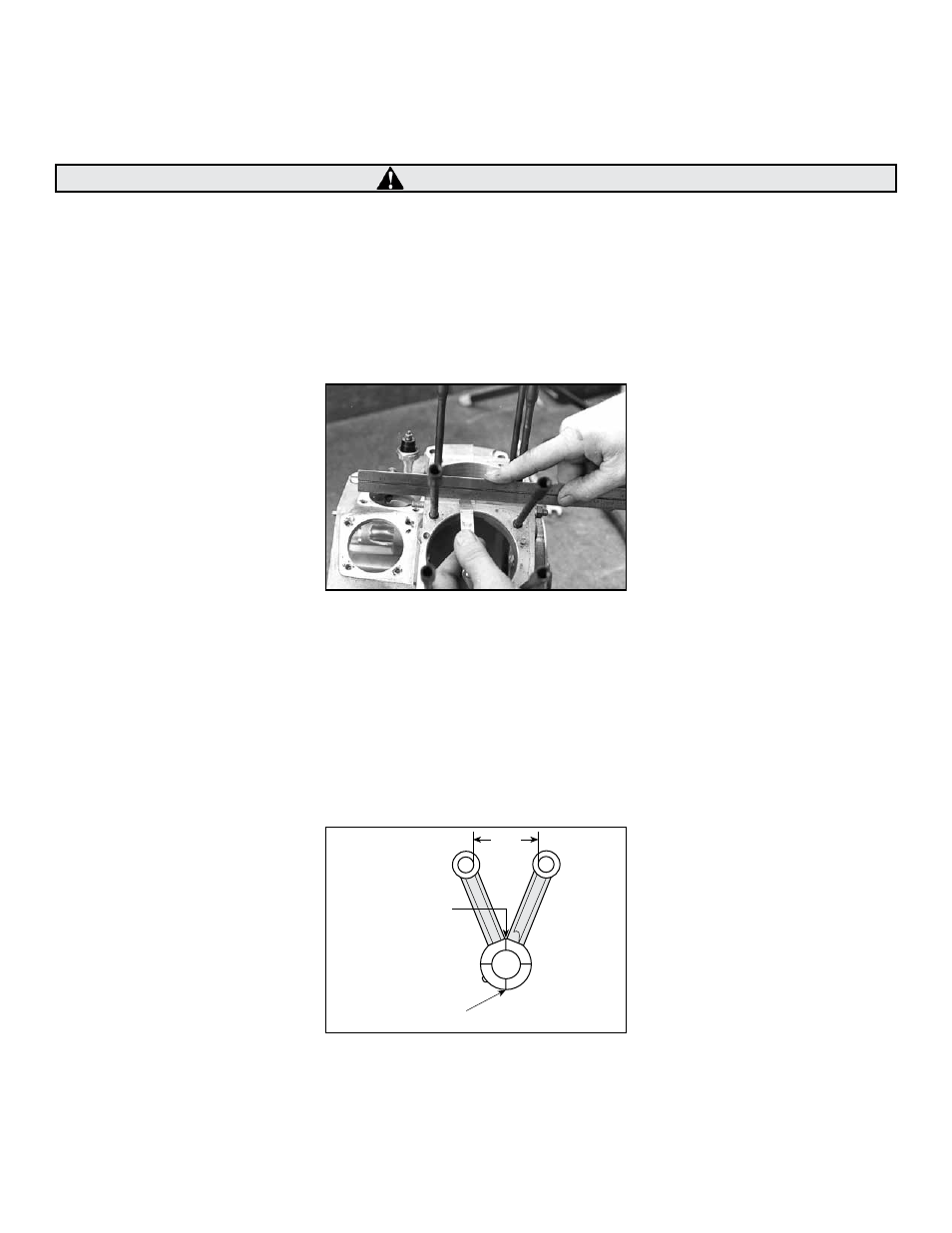

B. Place straight edge across base gasket surface. See Picture 1, below.

C. If any misalignment exists, remove cylinder base studs and place masking tape over cam and mainshaft bearings to keep chips out.

D. Place cases squarely in mill and take minimum cut necessary to clean up.

E. If stock cylinder studs are to be used, reinstall to original height. If studs are provided in kit, install to height that equals: thickness of

cylinder base flange, plus base gasket, plus cylinder base plate, plus washers, plus base nut. Use loctite stud and bearing mount to secure

studs.

2. Connecting Rod Preparation (All)

NOTE: If S&S connecting rods are used, follow instructions that accompany rods since rod preparation below has already been done.

If S&S rods are not used, perform following steps:

A. To insure adequate oil on sides of rods and matching thrust surfaces of flywheels, S&S recommends that four grooves be ground on

each side of both front and rear connecting rods. See Figure 1, below. Make these grooves .020" to .030" deep and .030" to .040" wide

and should be ground 90° from each other. After making grooves, remove all sharp edges and burrs with emery cloth.

B. With rods assembled, measure distance between rods at closest points in wristpin holes. If measurement exceeds 2.950" as shown in

Figure 1, grind female rod at points where male rod makes contact to achieve sufficient clearance.

NOTE: Rods clearanced to this dimension provide adequate clearance for strokes up to and including 5". Do not remove any more material than is

necessary to obtain required clearance.

CAUTION

Picture 1

Grind four oil

grooves on both

sides of forked rod

Grind stroke

clearance in

this area

2.950

Figure 1