S&S Cycle Bore Big Twin Stroker Kit 1936–1999 3 7/16 - 3 1/2 User Manual

Page 13

13

2. Piston and Cylinder Fitting (All)

Fit pistons to cylinders using piston fitting instructions provided. Check ring end gap and adjust as necessary. After gapping rings, keep them

separate so they can be installed in their proper locations later.

Piston Series #92-2700, #92-2730

with slotted oil ring groove

Close fit – .0015" to .002"

Loose fit – .0025" to .0035"

Piston Series #92-2500, #92-2510, #92-2600, #92-2610

Close fit – .002" to .0025"

Loose fit – .003" to .0035"

Piston Series #92-2720, #92-2730

with holed oil ring groove

Close fit – .002" to .003"

Loose fit – .0035" to .004"

Failure to follow instructions and perform required clearancing, installation and/or break-in procedures correctly may result in damage

to pistons and/or other engine components. S&S® voids its guarantee if pistons are not installed and/or broken in properly.

A. For maximum piston and ring life, fit pistons using appropriate close fit dimensions. Close fit requires absolute adherence to new engine

break-in as outlined.

B. For immediate drag strip use, fit pistons using loose fit dimensions. Attempt to break in rings and pistons with 50 easy miles if possible.

Piston and ring life will be reduced when using loose fit dimensions.

C. Measure all pistons across thrust faces 90° to wristpin holes. Make a series of measurements starting directly below oil ring groove and

ending at extreme bottom of skirt. Use widest measurement to represent size of piston. Some pistons measure widest at extreme bottom

of skirt. Others measure widest somewhere between oil ring groove and extreme bottom of skirt. If piston is notched for placement in rear

cylinder, use measurement directly above notch as extreme bottom of skirt measurement.

D. S&S recommends the use of #220-#280 grit stone for final honing of cylinders for all stock-bore stroke engines.

E. Follow procedure recommended in H-D® service manual for boring and honing S&S Sidewinder® cylinders for Evolution® engines. S&S cylinder torque

plate kit, S&S PN 53-0016, or H-D torque plates, H-D #33446, are required to simulate engine operating conditions. Cylinders may distort more than .001" if

torque plates are not used.

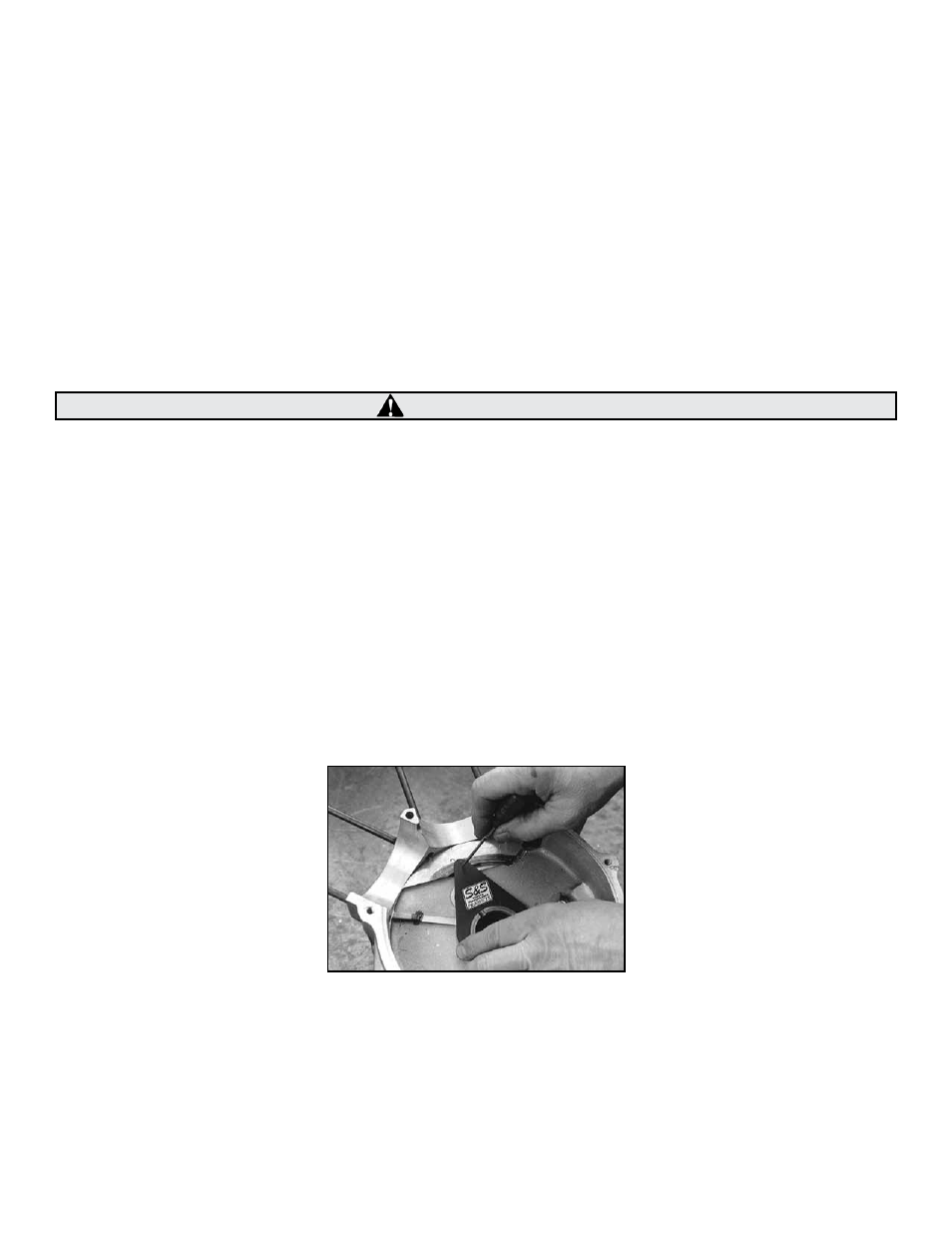

3. Crankcase and Piston Skirt Clearancing (All)

Crankpin Nut Clearance

Bosses on inside of cam side crankcase half must be clearanced for crankpin nut. See Picture 6, below.

NOTE: Crankpin nut will usually clear on stock crankcases for 80" engines when 41⁄4" or 43⁄8" stroke is used. When stroke 41⁄2" or longer is used, nut will

usually hit. S&S recommends all cases be checked no matter what stroke is used. S&S Crankpin Nut Clearancing Gauge, Part #53-0005, for cases 1958 and

later, and Part #53-0009 for cases 1957 and earlier are designed to mark crankcase that allows sufficient crankpin nut clearance for specific stroke to be

used.

If S&S gauge is not available, perform following procedure:

A. Paint bosses with machinist’s blue.

B. Use divider to scribe arc on blued bosses. See Figure 6, next page.

Piston Series, #92-2400, #92-2420

Close fit – .0008" to .0013"

Loose fit – .002" to .0025"

Piston Series #92-2800

with slotted oil ring groove

Close fit – .0025" to .003"

Loose fit – .0045" to .0055"

Piston Series,#92-2800, #92-2900

with holed oil ring groove

Close fit – .0035" to .004"

Loose fit – .005" to .006"

CAUTION

Picture 6