S&S Cycle Bore Big Twin Stroker Kit 1936–1999 3 7/16 - 3 1/2 User Manual

Page 14

14

NOTE: On panhead engines, above procedure is recommended to insure removal of minimum material necessary.

Early panhead cases are not as strong and are machined with oil supply passageways to heads closer to surface of boss. Removal of

excessive material may weaken thinner cases and/or break into oil passage.

C. Place masking tape over both ends of camshaft and mainshaft bearings to keep out chips.

D. Grind shaded areas to adjacent machined depth.

E. Mock up right side flywheel in crankcase half with mainshaft and crankpin installed with bearings, thrust washers, etc. in place.

F. Rotate flywheel and note any contact.

G. If flywheel does not rotate freely, check contact areas and grind more clearance.

H. Repeat procedure until sufficient clearance is obtained.

NOTE: A minimum of 1⁄16" clearance is required.

Insufficient clearance between crankpin nut and crankcase will cause contact and may damage components.

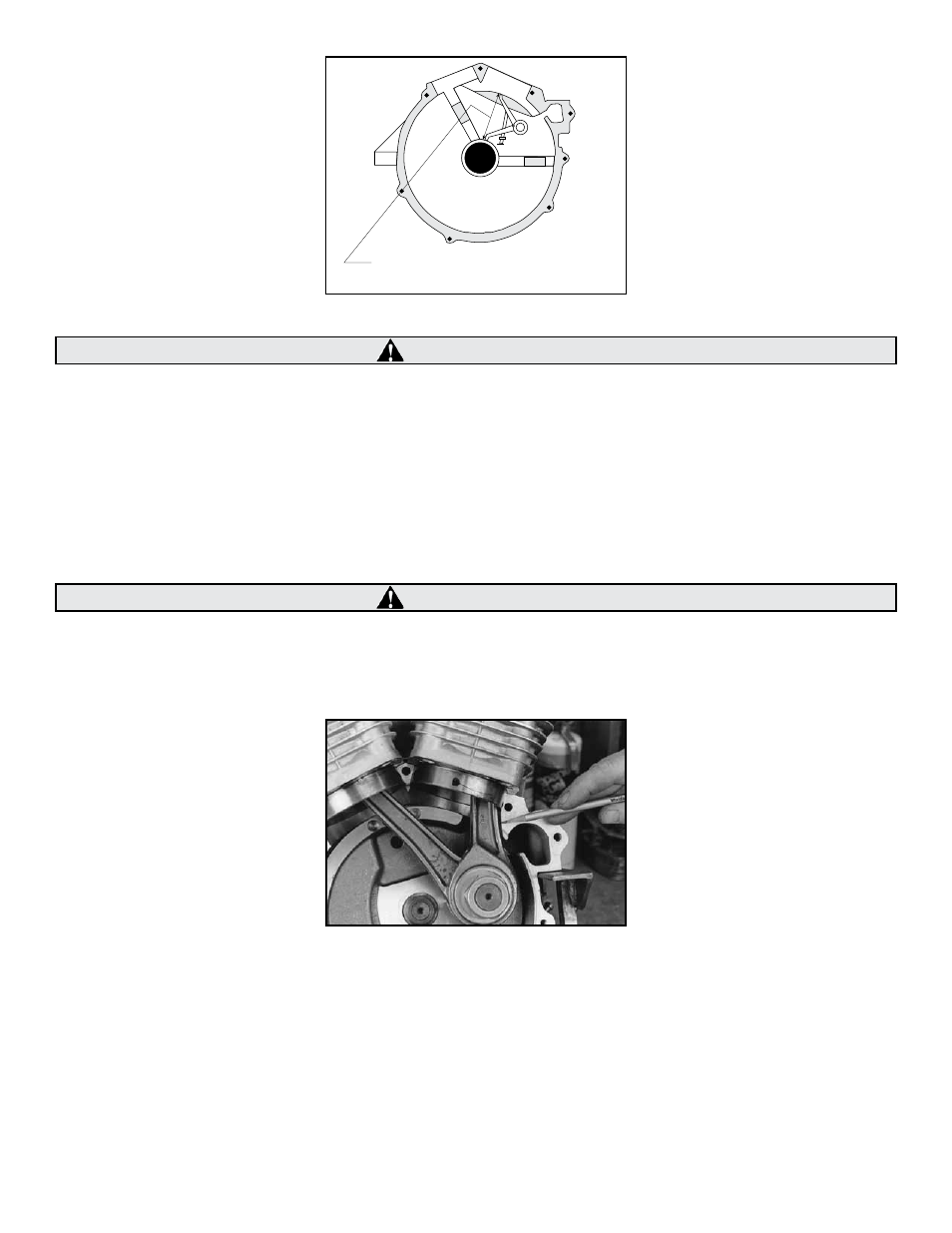

Connecting Rod Clearance

Front and rear of flywheel cavity inside crankcases andcylinder spigots must be clearanced for connecting rods. Picture 7, below shows rear side

of flywheel cavity.

NOTE: Clearance must be checked and filed if needed on front side also.

Procedure to check these points is performed as follows:

A. Mock up right side flywheel in crankcase half with mainshaft and crankpin installed with bearings, thrust washers, etc. in place.

B. Assemble pistons without rings on their proper connecting rods, and place connecting rods on crankpin. Installation of wristpin clips is not

necessary.

NOTE: If pistons have piston to piston clearance notches ground on thrust face edges, place notches toward center of engine. Consult piston installation

instructions included with pistons for proper piston direction placement.

Distance = 1/2 Stroke + 1/2 Dia. Crankpin

Nut

Across Points - 1/2 Outside

Dia. Main Race + 1/16" Clearance

Figure 6

CAUTION

CAUTION

Picture 7