S&S Cycle Bore Big Twin Stroker Kit 1936–1999 3 7/16 - 3 1/2 User Manual

Page 12

37/16 - 31/2 Big Bore Twin Stroker Kit 1936-1999

12

1. Lower Oil Return Holes (Pan & Shovel)

Big Twin cylinder oil return holes must be lowered in those stroker conversions where oil ring crosses stock oil return hole. This is necessary

to prevent oil from returning above oil ring which will cause engine to smoke.

NOTE: Oil rings will usually touch and/or cross oil return holes with installation of stroke 41⁄2" or longer. Strokes shorter than 41⁄2" do not require this step.

For strokes 41⁄2" and longer, perform following steps:

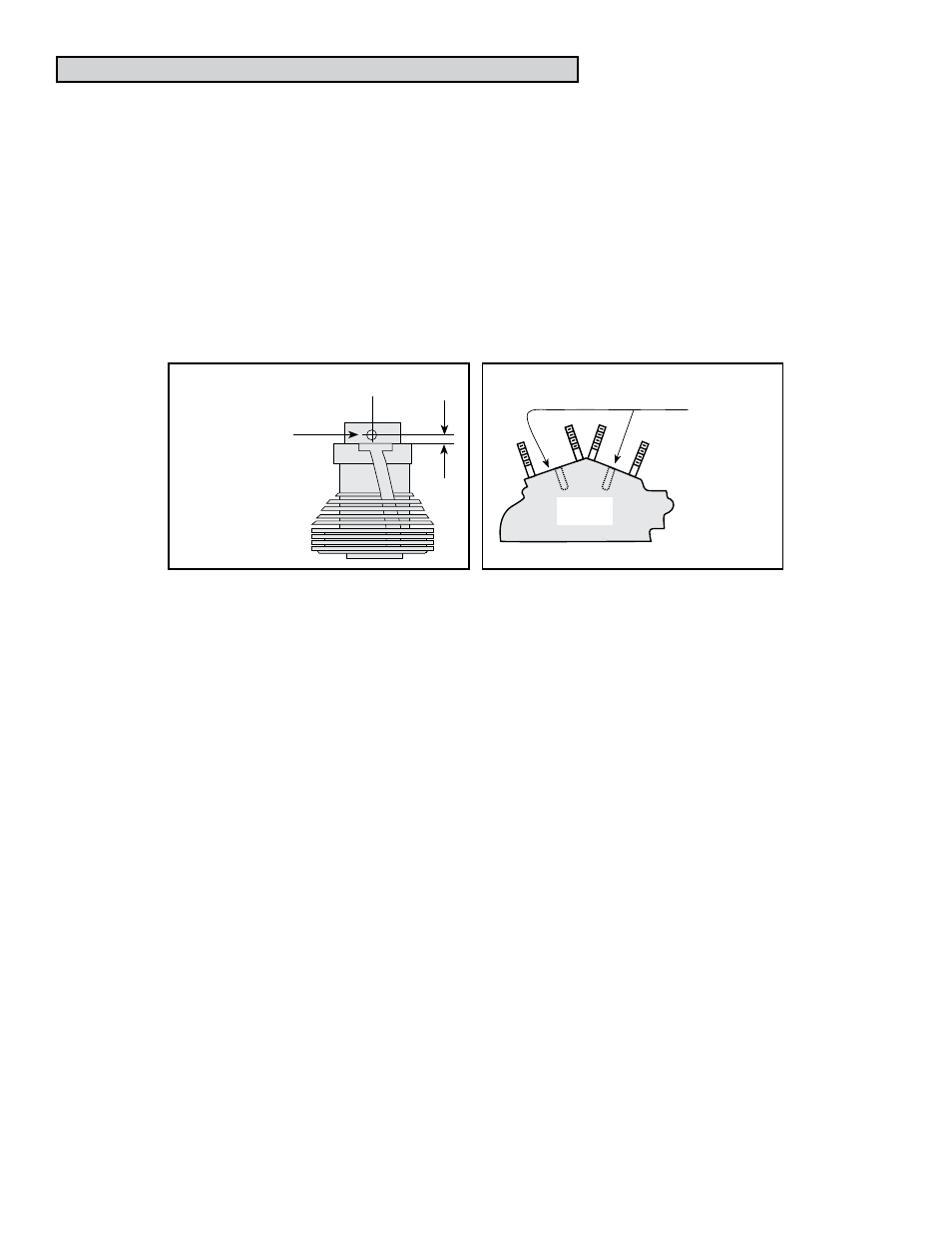

A. Directly in line with return hole in bottom of cylinder flange, drill 1⁄4" diameter hole centered 1⁄2" away from base gasket surface through

cylinder sleeve. See Figure 4, below left.

B. Place base gasket on cylinder base gasket surface, and punch 1⁄4" hole in gasket directly in center of oil return hole in base gasket surface.

C. Remove gasket from cylinder, and place on driveside crankcase half in its respective position. Mark crankcase gasket surface through 1⁄4”

diameter hole that has been punched in gasket.

D. Drill 1⁄4" diameter hole perpendicular into crankcase gasket surface 5⁄8" deep. See Figure 5, below right.

E. Perform steps A through D on other cylinder.

F. Bolt front and rear cylinders on drive side crankcase half.

G. Using hole drilled through sleeve in step A as a guide, drill a connecting hole to intercept hole drilled 5⁄8” deep in step D on each cylinder.

NOTE: If base plates are to be used, be sure they are in place.

H. Clean dirt, filings, etc. out of passageways.

I. Press one piece of 3⁄4" long x 3⁄8" O.D. steel tubing provided in kit into oil return hole in base gasket surface until tubing is flush with surface.

“Ream” hole slightly with drill to remove any burrs that may exist.

NOTE: A very tight press fit with 100% seal is not critical as tube will sufficiently divert oil flow to new hole. Loctite may be applied to tube if fit seems too

loose.

1/2"

Drill 1/4" diameter hole

Figure 4

Driveside

crankcase

Drill 1/4" diameter

hole, 5/8" deep

Figure 5