S&S Cycle Big Twin Engines with 3-1/2 and 3-5/8 Bore Crankcases and Special Application (SA) 4 Bore Crankcases User Manual

Page 9

Engines ordered for ‘84-’92 year group will require the

following additional parts for dual venting: S&S

®

air cleaner

backplate #17-0336 and hardware packet #17-0439. Both are

available from S&S.

NOTE - 1992 was a transitional year for some Harley-Davidson

®

models. While cylinder head venting was introduced in 1992,

many motorcycles sold as 1992 models retained crankcase

venting. Gear cover, gear cover gasket, lower rocker covers, and

lower rocker cover gaskets must be identified by year group to

determine possible vent arrangements.

NOTE - Using ‘93-up gear cover or gasket on S&S big twin engines

set up to vent out crankcase will result in large oil losses out

crankcase vent opening.

NOTE - Using ‘91-older lower rocker covers or gaskets in engines

set up for cylinder head venting will obstruct cylinder head vent

passages, causing oil leakage and possible damage to other

components. See Picture 22.

NOTE - If ‘93-up lower rocker covers are used in engine set up for

crankcase venting only, oil seepage past cylinder head vent

passage inserts may occur. It is recommended that ‘91-older lower

rocker covers be used in engine set up for crankcase venting only.

Install vent hardware (big twin):

1. For crankcase and dual venting, install 45˚ elbow, #31-2022,

in crankcase vent opening per S&S Crankcase Instructions

#31-0000M. If engine to vent out cylinder heads only, plug

crankcase vent opening with socket head pipe plug

#31-2023. Steel fittings such as elbow and plug must be

coated with anti-seize thread sealant such as Slic-Tite

®

or Teflon

®

tape before installation in crankcase or

cylinder head.

2. For crankcase venting only, install threaded inserts #90-4026

in cylinder head air cleaner mounting bolt holes. See

Carburetor Instruction Sheet #51-1012.

Note- Shovelhead engines vent out crankcase only.

INSTALL PISTONS AND CYLINDERS

(All Unassembled)

1. Identify front and rear pistons according to “Piston

Installation” section in S&S Pistons Instruction Sheet

#51-1028. Piston Series number will appear on box

containing piston assembly.

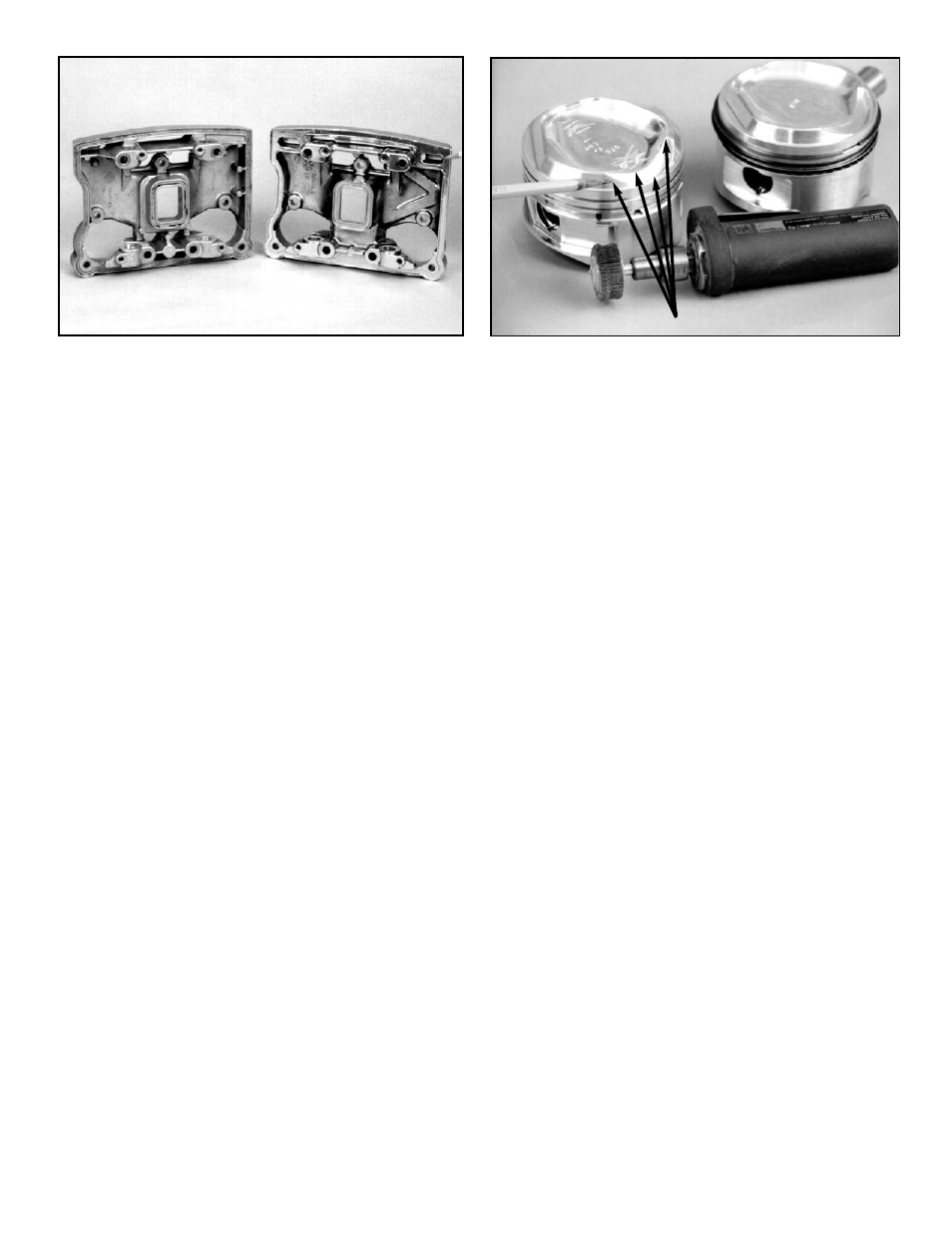

2. Inspect pistons, especially areas around machined surfaces

such as ring grooves and wristpin holes, for burrs. De-burr as

necessary, taking care to remove particles that could become

dislodged inside engine.

3. On big twin engines that will be operated in extremely hot

climates such as American South, Southwest, or areas with

only low octane gasoline available, carefully round sharp

edges on piston dome and in combustion chamber. A die

grinder and small, flexible sanding wheel work well for this.

See Picture 22.

4. Measure ring end gaps and adjust as necessary. See S&S

Piston Instruction Sheet #51-1028, “Ring Installation” for gap

specification applications.

5. Thoroughly clean cylinders, pistons, rings, wristpins, and

wristpin retainers in solvent, then hot, soapy water. Take

special care to flush oil passages, and pass clean, white cloth

back and forth through wristpin bores. Dry all with

compressed air and place on clean, dry surface.

6. S&S recommends installing all cylinder base gaskets dry.

Builders who prefer sealant may use sealant of choice on

shovelheads, but big twin gaskets are different material and

must be installed dry. Be sure holes in gaskets align with

cylinder base dowels and oil holes.

7. Install rings on pistons as described in Piston Instruction

Sheet. S&S recommends covering cylinder studs with 3/8” I.D.

fuel line to protect rings until cylinder installed.

8.

Lubricate connecting rod wristpin bushings with light coat of

assembly lube. Install rear piston, wristpin and retainer on

connecting rod per piston instructions.

9. If big twin cylinders, install cylinder head alignment dowels

in cylinder.

NOTE - Tight clearances resulting from reinforced S&S cylinder

design require that S&S shovelhead base nuts and two head bolts

(ones nearest exhaust pipes on cam side of engine) be inserted

and held in place as cylinder lowered over studs. See Instructions

for S&S Sidewinder

®

Big Bore Cylinders No. 1000, page 12.

9

Picture 21

Picture 22

1992-Earlier

1993-Later

Round areas shown in both valve reliefs.