Caution – S&S Cycle Big Twin Engines with 3-1/2 and 3-5/8 Bore Crankcases and Special Application (SA) 4 Bore Crankcases User Manual

Page 3

ASSEMBLY

NOTE - While S&S

®

has made every effort to insure that parts are

correct, it is the engine builder’s responsibility to confirm fit and

finish of all parts provided with engines prior to assembly. Parts

are deburred at S&S and usually require no further preparation,

but must also be inspected by installer. Individual parts should not

be removed from protective plastic wrappers until needed. After

removal from plastic, it is imperative that parts be thoroughly

cleaned and dried, preferably with compressed air. When

present, rust preventative must be completely removed.

Additionally, gaskets must be closely inspected for particles that

could become dislodged and damage engine. If assembly of

engine must be interrupted, seal openings and cover engine with

plastic to protect from destructive contaminants.

Failure to observe the above may result in engine damage not

covered under warranty.

FLYWHEELS

(All Unassembled engines)

Carefully read S&S big twin Pinion Shaft Installations #51-1021,

S&S Connecting Rod Instructions #51-1025 and Installation

Instructions for S&S Super Stock

®

and Special Application big twin

Crankcases #51-1063 before proceeding.

1. Confirm that correct brass plug has been installed in end

of pinion shaft. Plug for side oiling engines (pre-1973)

will be solid. Plug for 1973-up end oiling engines will

have 3/32” hole.

2. Confirm pinion shaft main bearing fit. Bearing supplied

should be correct size, but must be verified by engine builder

according to procedure in S&S Crankcase Instructions, page

9. Flywheel assembly can then be prepared for installation as

described in special instructions for fully assembled S&S

flywheel sets, #51-1019.

CRANKCASES (All Unassembled Engines)

Refer to S&S Crankcase Instructions #51-1063 for information on

preparing crankcases. Additionally, blow out cam bearing and all

oil passages with compressed air.

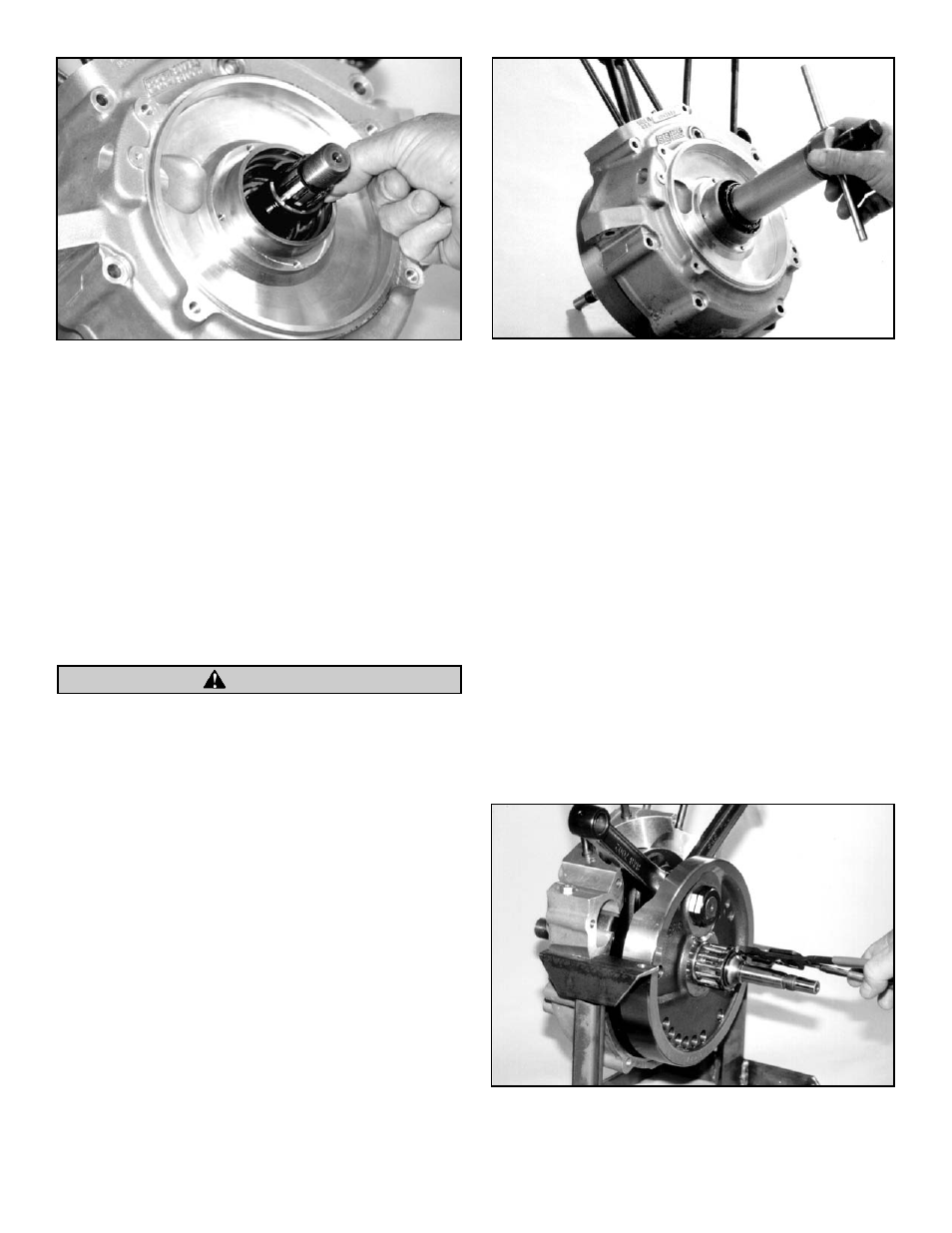

INSTALL FLYWHEEL ASSEMBLY IN CRANKCASE

(All Unassembled Engines)

1. Thoroughly clean parts according to instructions previously

mentioned. Apply coat of assembly lube to bearing surface

of sprocket shaft and inner race of Timken

®

bearing. Install

bearing on shaft with appropriate tool. See Picture 1.

NOTE - S&S does not recommend using a press to install sprocket

shaft bearings, as this can push flywheels out of true. Correct

bearing installation tools are available from Harley-Davidson

®

and other sources.

2. Apply coat of petroleum jelly to Timken

®

bearing installed in

Step 1. See Picture 2.

3. Place left side crankcase half on sprocket shaft and

bearing, insuring that connecting rods are in correct

positions. See Picture 3.

4. Install

Timken

®

bearing spacer. See Picture 4.

5. Lubricate rollers of remaining Timken

®

bearing with

petroleum jelly. Apply assembly lube to bearing inner race

and sprocket shaft bearing surface. Install bearing on shaft

with appropriate tool. See Picture 5.

3

Picture 4

Picture 5

CAUTION

Picture 6