Caution – S&S Cycle Big Twin Engines with 3-1/2 and 3-5/8 Bore Crankcases and Special Application (SA) 4 Bore Crankcases User Manual

Page 10

10. Apply very light film of motor oil to piston skirts and

cylinder bores and install rear cylinder. Refer to Installation

Instructions for S&S

®

Sidewinder

®

Big Bore Cylinders #1000,

pages 12-13. Install rear cylinder head, referring to following

section as necessary.

NOTE - IOn big twin engines, if engine builder chooses to install

front cylinder before installing rear head, rear cylinder should be

temporarily secured with head bolt and washers. If cylinder not

secured, piston can lift cylinder and disturb base gasket if

flywheels rotated.

11. Repeat piston installation for front cylinder and

cylinder head.

INSTALL CYLINDER HEADS (All Unassembled)

For big twin engines, complete installation per Super Stock

®

Cylinder Head Instruction Sheet #51-1042. For shovelhead

engines, refer to Installation Instructions for S&S Sidewinder

®

Big

Bore Cylinders #51-1014. Note that shovel intake manifold and

top end oil supply lines should be installed before headbolts

tightened on shovelhead engines. If S&S shovelhead heads used,

rocker cover assemblies must be installed using cap screws

provided by S&S.

NOTE - S&S shovelhead engines are supplied with several

different camshafts. S&S cylinder heads assembled by S&S are

compatible with all. Stock heads are not. If different camshaft,

non-S&S heads, or S&S heads assembled by other source are used,

engine builder must confirm lift capability of valve springs and

collars as well as valve-to-valve clearance. Refer to Installation

Information for S&S big twin camshafts.

Failure to establish correct clearances can cause extensive

engine damage not covered under warranty.

PUSHROD PREPARATION (All)

1. Disassemble pushrods and pushrod tube covers (covers not

supplied with engine). Clean thoroughly and dry with

compressed air.

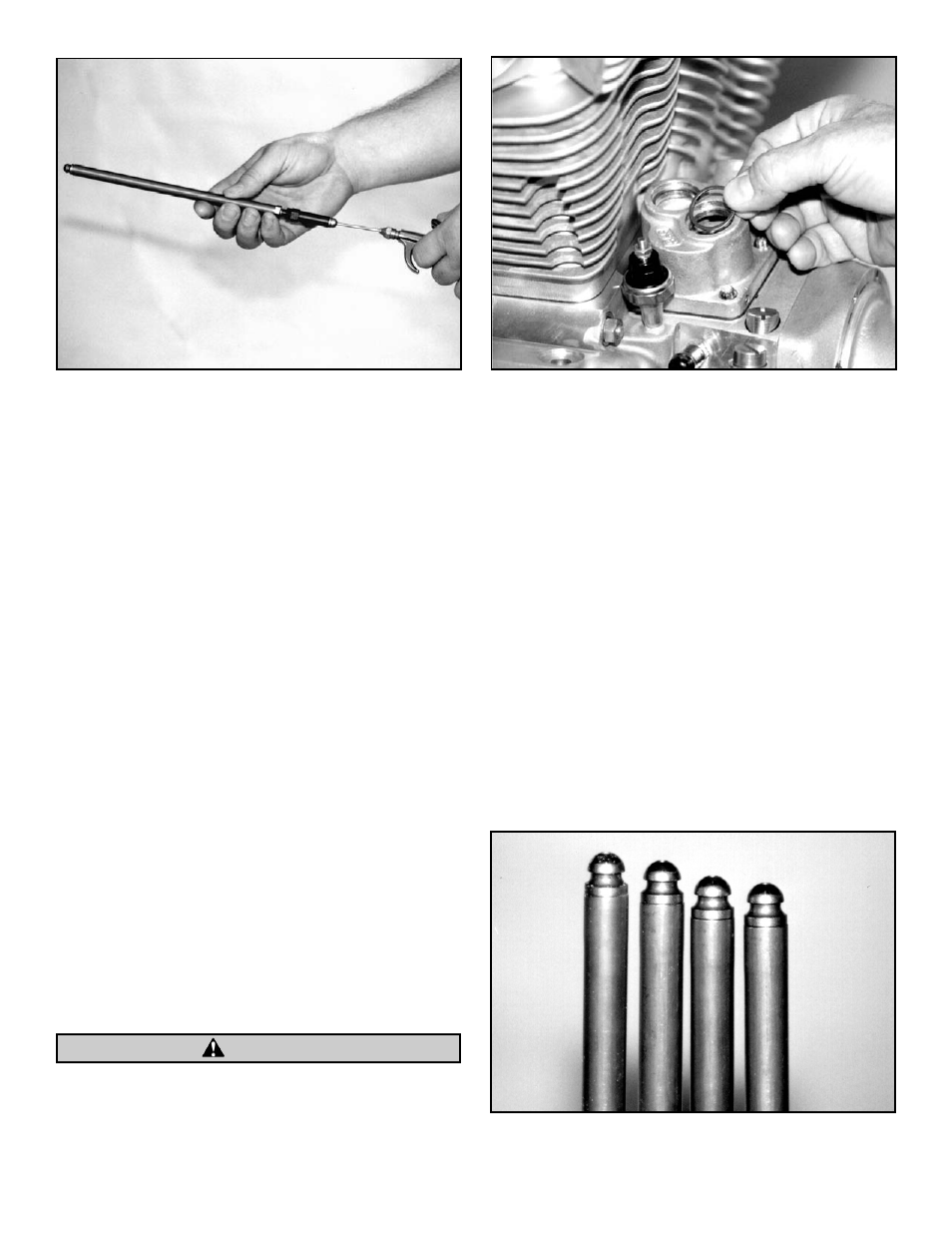

2. For big twin style pushrods, blow compressed air through oil

passage in each pushrod to confirm that passage is clean and

free of debris and obstruction. See Picture 23.

3. Assemble pushrod tube cover assemblies according to

Harley-Davidson

®

Service Manual.

4. Insert pushrod tube O-ring spacers in lifter blocks (big twin).

See Picture 24.

5. Install O-rings or corks in lifter blocks. Normally corks are

used only with shovelheads.

6. Install thick pushrod tube O-rings or corks in cylinder heads.

7.

Determine pushrod placement by comparing lengths of each

pushrod (not including adjuster). Longest pushrod is for

front exhaust, next longest for rear exhaust, shortest for rear

intake, remaining pushrod for front intake. See Picture 25.

Refer to Pushrod Instruction Sheet #51-1035 as needed.

8. Screw pushrod/lifter adjusters in to shortest length and set

pushrods aside.

10

Picture 23

Picture 24

CAUTION

Picture 25