Warning – S&S Cycle Big Twin Engines with 3-1/2 and 3-5/8 Bore Crankcases and Special Application (SA) 4 Bore Crankcases User Manual

Page 4

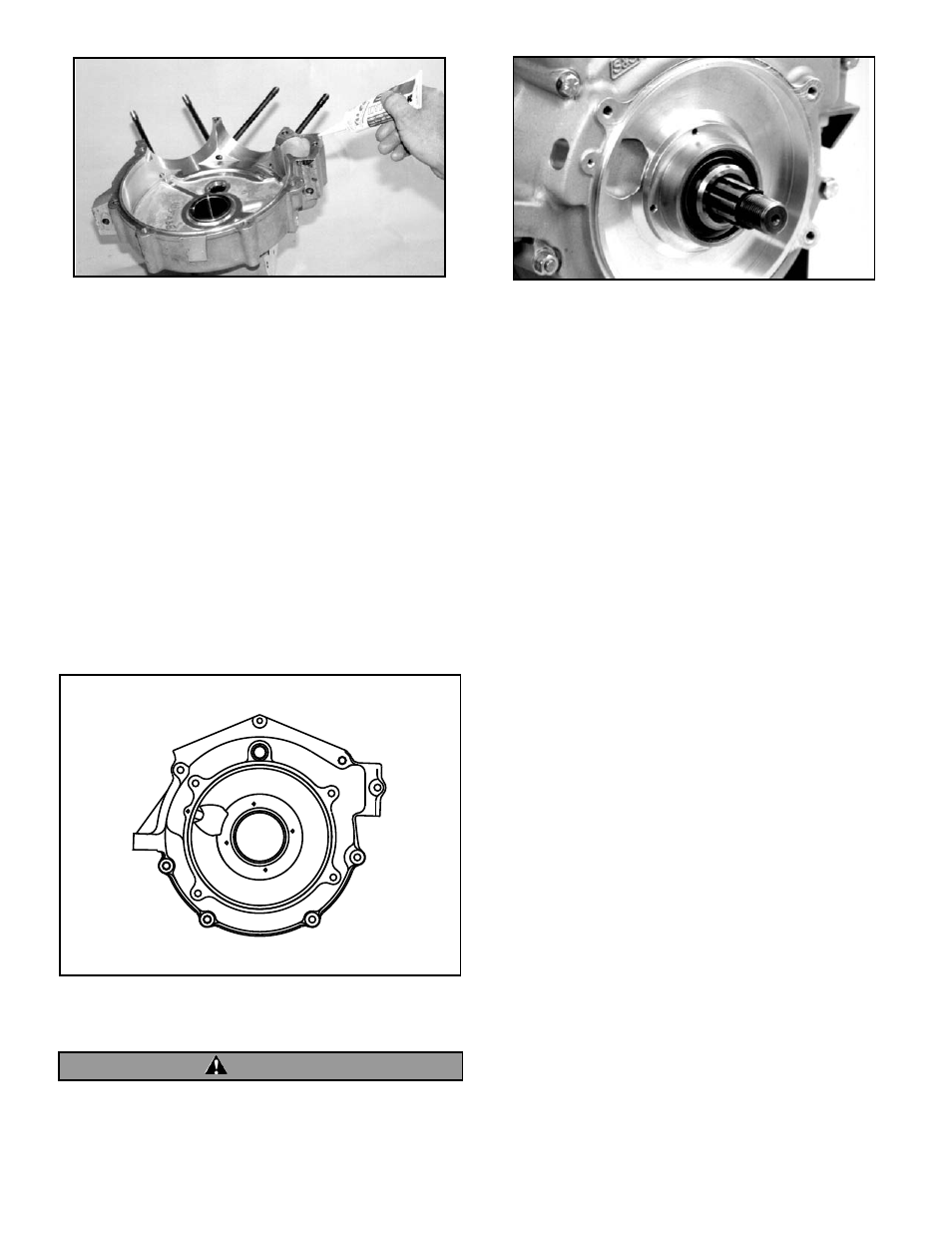

6. Lubricate pinion bearing and pinion shaft bearing boss with

petroleum jelly. Install bearing and secure with pinion shaft

main bearing snap ring. See Picture 6 on previous page.

NOTE - Pinion and sprocket shaft bearings should be correct sizes,

but it is engine builder’s responsibility to confirm flywheel

endplay, connecting rod sideplay, bearing fit, and all clearances

in unassembled engine at time of assembly. It is of particular

importance to check flywheel endplay and install different

Timken

®

bearing spacer if necessary. Refer to Harley-Davidson

®

Service Manual for detailed explanation of required procedure.

NOTE - Harley-Davidson

®

has used different style pinion bearings

in various models, some requiring different snap rings. Snap ring

supplied by S&S

®

or identical replacement must be used with

pinion bearing supplied in S&S engine.

NOTE - Ends of snap ring are rounded on one side, sharp on the

other. Install snap ring with sharp edge out, away from flywheels.

ASSEMBLE CRANKCASE HALVES

Gasoline, lacquer thinner, and many solvents are extremely

flammable. Fumes may be explosive and toxic if inhaled.

Read and follow the manufacturers’ instructions if applicable,

and use these materials only in a well ventilated area away

from sparks and open flame.

1.

Wipe down mating gasket surfaces of crankcase halves with

lacquer thinner. Remove residue with clean, dry cloth, then

apply sealant of choice to pinion side crankcase. Take care to

avoid breather cavity and other areas where sealant might

reach inside of engine. See Picture7. Coat right main

bearing race with petroleum jelly. If applicable, allow sealant

to cure according to manufacturer’s instructions, then join

left and right crankcase halves.

NOTE - In most instances S&S uses Hylomar

®

or Threebond

®

1104

to seal crankcase. Use any sealant carefully to prevent excess

from entering engine and obstructing oil passages or

contaminating oil supply.

2. Install crankcase studs and washers according to

crankcase instructions.

Note - Alignment studs for S&S generator and alternator

crankcases are in same locations B, E, & G. See Diagram 1. They

must be installed before other studs and bolts. Fit is tight, so

alignment studs must be lubricated with assembly lube, then

tapped through case assembly with plastic mallet.

3. Tighten 5/16” case bolts and studs to 15-18 ft-lbs, 1/4” center

bolt to 10-12 ft-lbs. See Diagram 1 for identification, and

tighten fasteners in following sequence: G-B-E-F-H-D-C-A.

4. Install drive sprocket spacer and sprocket shaft oil seal in

main bearing race of left case.

NOTE - Because of semi-dry primary housing in shovelheads and

sealed, wet primary in big twin models, S&S installs shovelhead

sprocket shaft seals with spring facing inside, big twin seals with

spring out. See Picture 8.

5. Allow crankcase sealant to cure per mfr.’s instructions, then

pour four ounces of motor oil over bearing end of

connecting rod assembly and into flywheel cavity. Rotate

flywheels several times to distribute oil over connecting rod

bearings. Assembly should turn freely and without binding.

4

Picture 7

Picture 8 (Big Twin Models)

Diagram 1

A

B

C

D

E

F

G

H

WARNING