Caution – S&S Cycle Big Twin Engines with 3-1/2 and 3-5/8 Bore Crankcases and Special Application (SA) 4 Bore Crankcases User Manual

Page 11

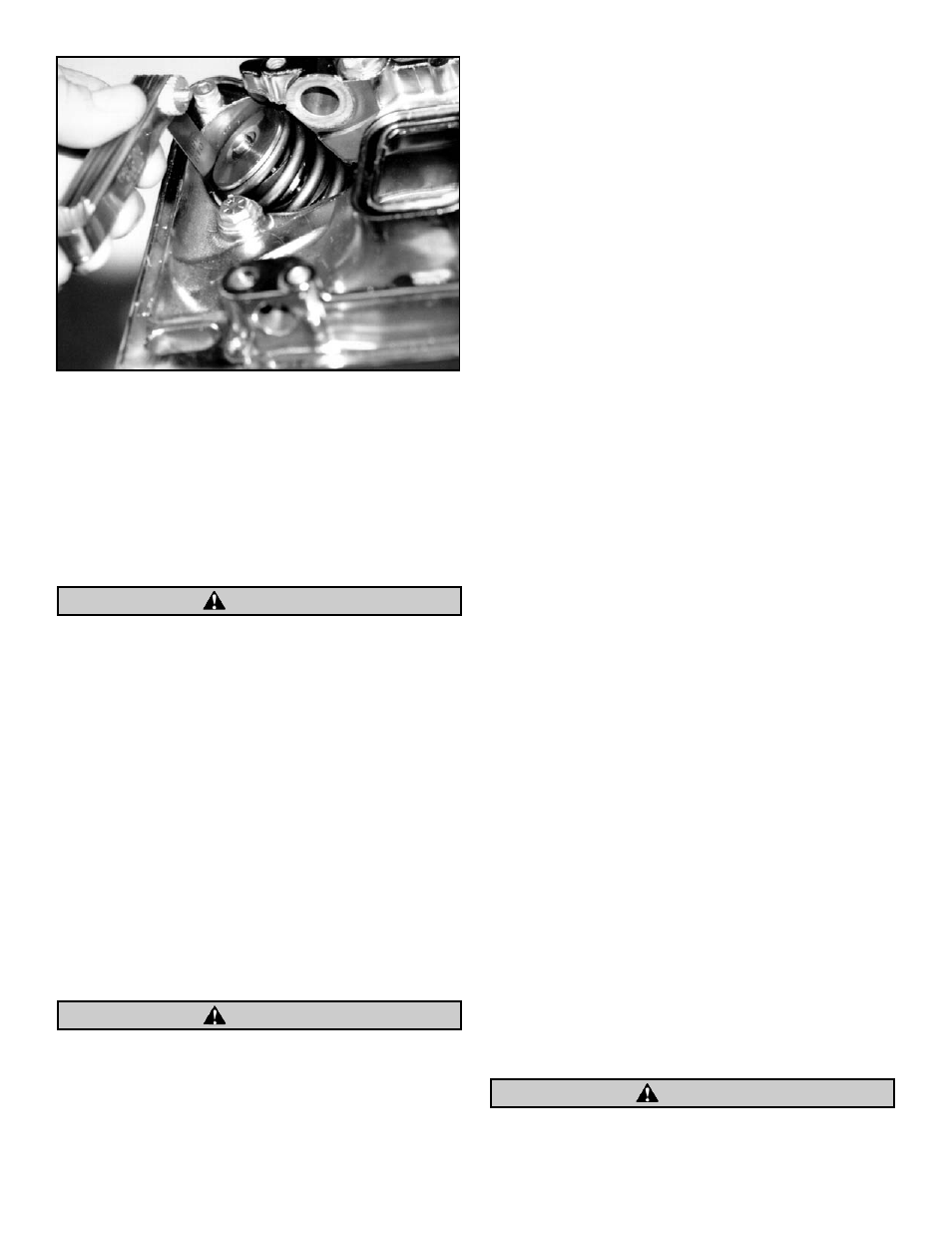

INSTALL LOWER ROCKER COVERS (All big twin)

Rocker covers must be installed with hardened flat washers and

grade 8 bolts of proper length. Correct hardware is available

from aftermarket suppliers and Harley-Davidson

®

.

Note - Consult S&S

®

shovelhead Cylinder Head instruction sheet

#00-9001 for assembly and installation of shovelhead cylinder

heads and rocker cover assemblies.

Lockwashers should not be used inside engine. Lockwashers

cut metal surfaces and can cause damaging metal particles to

be distributed through engine by circulating oil.

1. All parts must be clean and dry. To install, place lower rocker

cover gaskets on cylinder head with silicone bead facing up.

A small amount of Hylomar

®

or other thin gasket sealant

may be used in corners to hold gasket in place on head. No

other sealant should be used.

2. Place lower rocker cover on gasket and cylinder head and

hold loosely in place with 1/4” bolts and flatwashers. Verify

that cover is positioned so as not to interfere with valve

spring operation (See Picture 26), then tighten bolts to

10-13 ft-lbs as described in Harley-Davidson

®

service

manual. In cases where clearance between cover and spring

is insufficient, bolts may be loosened and cover

repositioned slightly to gain clearance. It is also possible to

take cover off engine and remove small amount of metal

from cover to increase clearance. After clearance

confirmed, install two short 5/16” bolts and washers on left

or drive side of engine and tighten to 15-18 ft-lbs.

Operating engine without sufficient clearance between valve

spring and rocker cover will cause engine damage not

covered under warranty.

3. Clean rocker arms and shafts and dry with compressed air.

Coat rocker shafts, rollers, bushings, valves and pushrod tips,

and ends of rocker arms with assembly lube.

ROCKER ARM/PUSHROD INSTALLATION AND

ADJUSTMENT (big twin)

NOTE - S&S pushrods are designed with emphasis on strength.

Weaker pushrods may flex under load, resulting in loss of power,

increased cranking compression, or detonation.

1. Rotate flywheels in direction of normal engine rotation until

both lifters for front cylinder at lowest position on camshaft.

Front piston will be at or near TDC on compression stroke

when lifters in correct position.

2.

Identify pushrods as explained in Step 6, “Pushrods” section.

Hold pushrod tube for front intake in place and pass correct

pushrod, adjuster end down, through cylinder head and

pushrod tube. Repeat for front exhaust.

NOTE - Some engine builders prefer to install and adjust pushrods

one at a time, beginning with intake.

3. Place front rocker arms in lower rocker cover and install

shafts, confirming that reliefs in shafts align with bolt holes

in rocker covers. Rocker arms must sit squarely on valve tips.

If not, loosen rocker cover bolts and reposition cover slightly

to obtain correct alignment. Do not overlook valve spring-

cover clearance as described previously. With proper rocker-

valve stem alignment and valve spring-rocker cover

clearance confirmed, install two 5/16” bolts and flat washers

in lower cover and tighten to 15-18 ft-lbs.

4. If

HL

2

T kit is used, pushrods must be adjusted according to

Installation Instructions for S&S Hydraulic Lifter Limited

Travel Kit #51-1039.

NOTE - Recommended pushrod adjustment with kit is 3 flats

or 1/2 turn shorter than zero lash with lifters completely

bled down.

Pushrods will be noisy if set at zero lash. If HL

2

T kit not

used, adjust pushrods according to S&S Pushrod Instruction

Sheet #51-1035.

5. Install middle and upper rocker covers and gaskets on

front head. If applicable, install center sections with

umbrella valves towards center off engine. Insure that

small center gasket in lower cover does not become

dislodged. A dab of grease or adhesive may be used to

hold gasket in place. Tighten screws to 10-13 ft-lbs. Install

pushrod cover retainer clips.

6. Rotate flywheels until rear piston reaches TDC on

compression stroke (315 flywheel degrees past front piston

TDC) and both rear lifters are in lowest position on cam.

Repeat procedure for installing pushrods, rockers, and

covers, installing longest remaining pushrod in exhaust.

7. After pushrod adjustment completed per instructions, rotate

flywheels several revolutions in direction of normal flywheel

travel to confirm that engine turns freely.

NOTE - Do not force engine. If resistance encountered, determine

and correct cause before continuing.

Forcing engine against resistance may cause damage not

covered under warranty.

11

Picture 26

CAUTION

CAUTION

CAUTION