Warning, Caution – S&S Cycle Big Twin Engines with 3-1/2 and 3-5/8 Bore Crankcases and Special Application (SA) 4 Bore Crankcases User Manual

Page 2

INTRODUCTION

S&S

®

big twin and shovelhead engines are available in several

stages of completion. Final assembly depends upon which version

was purchased. Engine Instructions often refer to procedures

described in other S&S instructions or a Harley-Davidson

®

Service

Manual. These materials should be cross-referenced as necessary.

Because of the large number of instructions provided with each

engine, it is recommended that they be arranged in sequence

according to Instruction Sheet # printed in top left corner.

In most instances, assembly of S&S big twin and shovelhead

engines is similar. Exceptions will be noted where applicable. All

engines are designed for frames that accept Harley-Davidson

®

big

twin engines. Most fit stock Harley-Davidson

®

and similar frames

without modification. Some engines are significantly taller than

stock as a result of increased stroke, and may require frame

modifications. While this applies mostly to 96, 98 and 103 cubic

inch shovelhead and 103 in. big twin engines, S&S strongly

recommends trial-fitting every engine before frame is painted or

powder coated.

Because the Special Application crankcase is 1/4 inch wider than

stock, fit of exhaust, rear brake master cylinder, and foot

controls must be closely checked when installing 4 inch bore or

other engines with SA crankcases. Some components may

require modification.

In some instances, brake master cylinder must be spaced out

from frame to clear SA crankcase. UNDER NO

CIRCUMSTANCES SHOULD MASTER CYLINDER OR BRAKE LINE

BE ALLOWED TO CONTACT EXHAUST PIPE IN FINAL

INSTALLATION. Heat transferred to brake fluid may expand

and cause brakes to seize, resulting in possible fire hazard

and loss of control of motorcycle with injury or death to rider

and others.

IMPORTANT NOTES:

●

Lubrication - S&S supplies Torco

®

Engine Assembly Lube with

each engine. It should be used as specified in following

instructions. While other brands of assembly lube are

acceptable, other lubricants are not. In no instance should an

aerosol lubricant be substituted for assembly lube.

●

Engine tuning - Ignition timing and carburetor jetting are

responsibilities of the customer. General tuning guidelines

appear in these instructions and Carburetor Instruction

Sheet #51-1012.

Incorrect ignition or carburetor tuning can cause extensive

engine damage not covered under warranty.

●

Powder coating and polishing - While S&S does manufacture

some powdercoated engines, it does not recommend having

engine parts powdercoated or otherwise modified

elsewhere. Many such procedures leave abrasive residues

which are difficult to remove completely. Also, powder

coating is cured at high temperatures that can change the

strength characteristics of some metals.

Glass bead and polishing residues are abrasive and can be

difficult to remove from recesses and small passages.

Abrasive residues can cause oil contamination and extensive

engine damage. Engine damage caused by powder coating,

polishing, glass bead blasting, or other modification will not

be covered under warranty.

2

WARNING

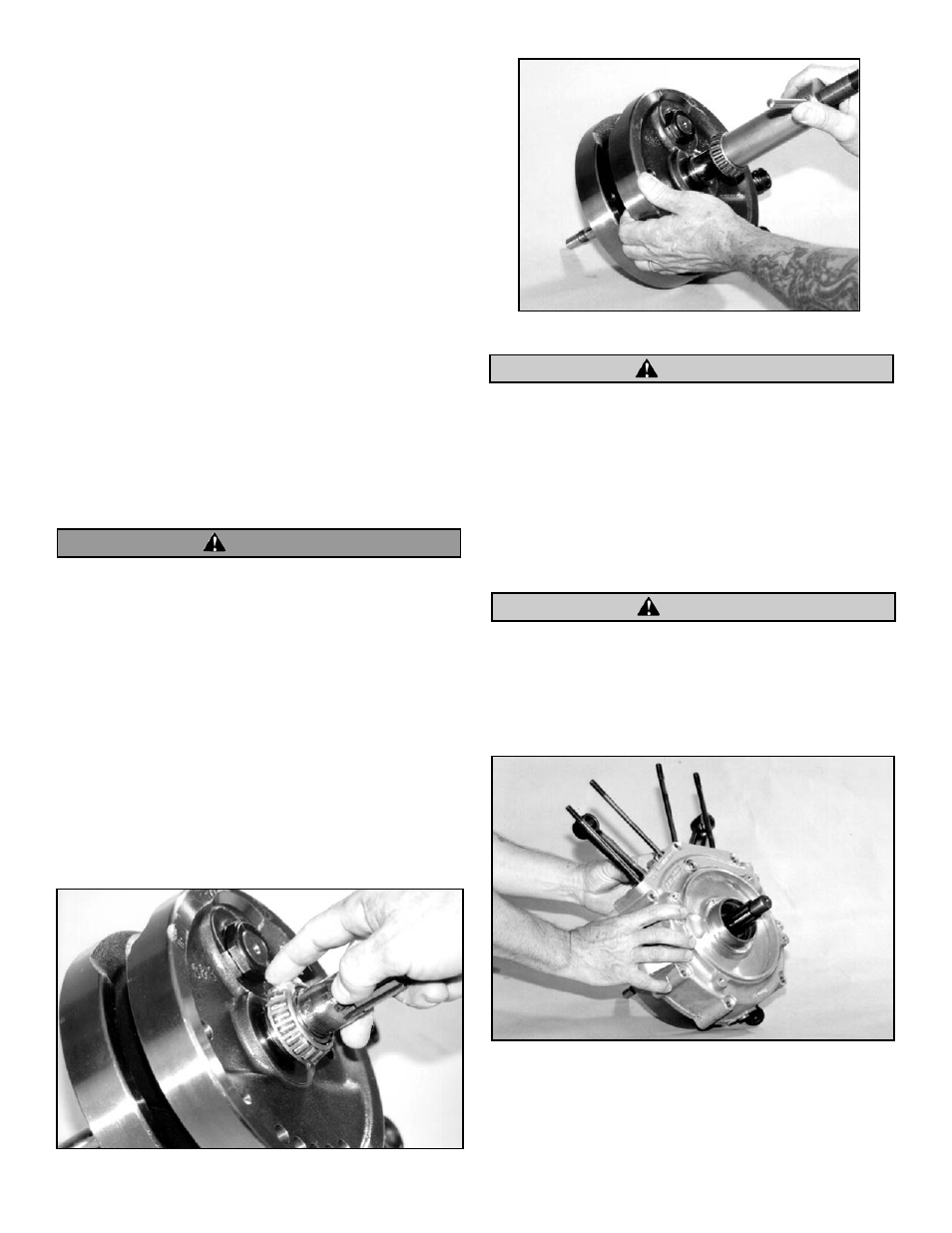

Picture 2

Picture 1

CAUTION

CAUTION

Picture 3