Caution – S&S Cycle Big Twin Engines with 3-1/2 and 3-5/8 Bore Crankcases and Special Application (SA) 4 Bore Crankcases User Manual

Page 7

NOTE - Drive gear spacer will not completely fill space between

oil pump drive gear and pinion gear. A gap of up to .125” may

exist and is normal. Engine rotation keeps oil pump gear in place

during normal operation. Spacer prevents gear and key from

becoming disengaged if engine rotated backwards.

Installing pinion gear or nut without Loctite

®

can cause

damage to shaft, nut, or other parts.

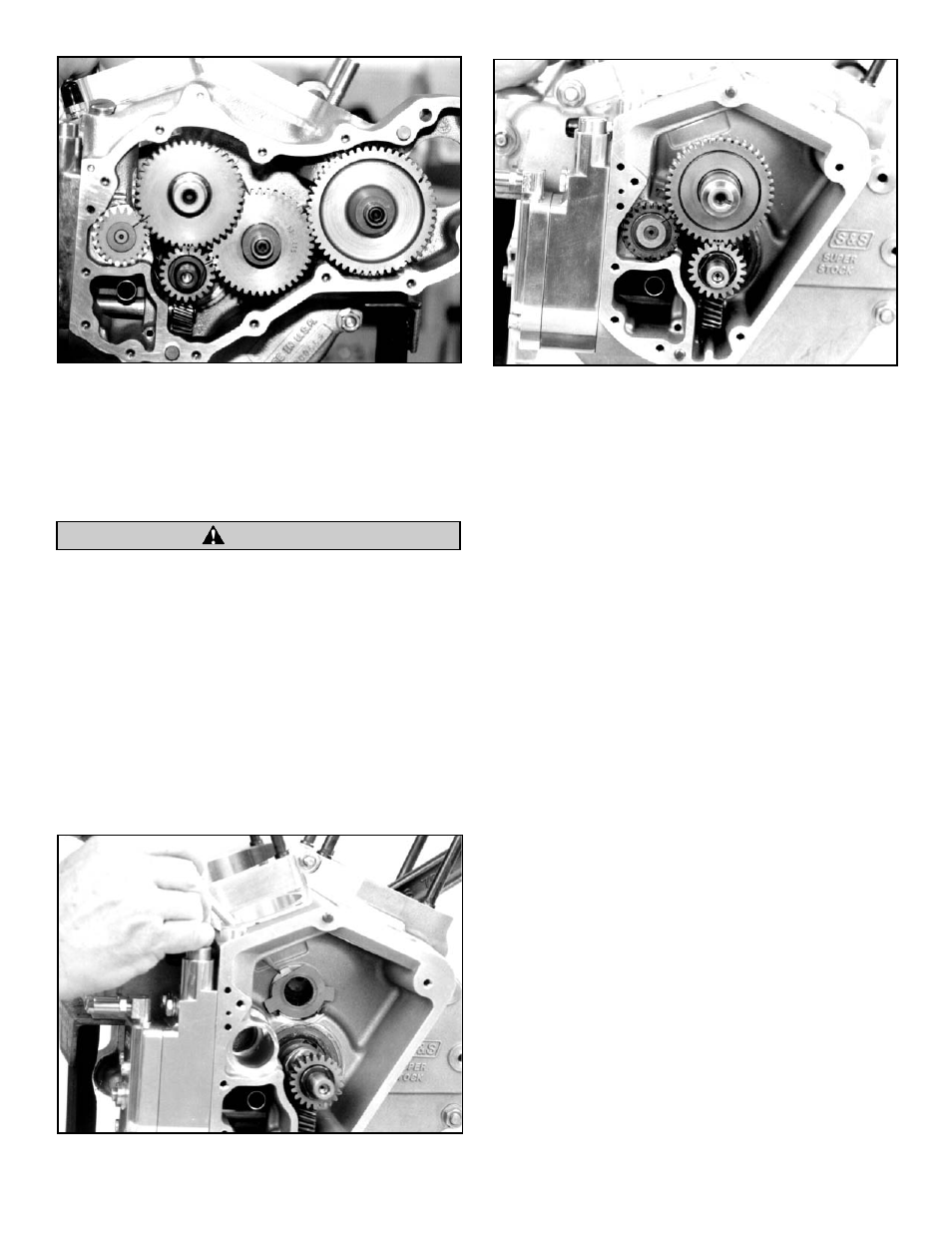

3. In Generator engines only, install intermediate and circuit

breaker drive gears, and spacers if applicable.

NOTE - To increase bushing surface area, S&S

®

intermediate

and circuit breaker drive gears do not utilize spacers. Correct

end play of .003-.007 in. must be established using shims

provided with gears.

Timing mark on circuit breaker drive gear must align with mark

on pinion gear. Other mark on pinion gear must be positioned

to align with mark on camshaft gear when camshaft installed.

See Picture 16A.

INSTALL BREATHER GEAR, CAMSHAFT, AND GEAR

COVER (All Unassembled)

1. Thoroughly clean and dry all parts including camshaft

lockwasher and thrust washer. Carefully inspect breather

gear for burrs and remove as necessary. Inspect edges of

crankshaft breather for burrs and smoothness. Cam thrust

washer and breather gear shims should be correct size, but

endplay of camshaft and breather gear must be verified by

customer. Refer to S&S Camshaft Instruction Sheet #51-1026,

Gear Cover Instructions #51-1032, and Harley-Davidson

®

Service Manual as necessary.

2. Apply light coat of Vaseline

®

to cam bearing, and coat of

assembly lube to cam lobes, camshaft lockwasher,

thrustwasher, breather gear, and to breather gear cavity

inside engine.

3. Place camshaft lockwasher in case with ears down and flat

edge towards rear of engine. See Picture 17.

4. Install thrust washer over end of cam and place assembly in

engine. During installation, rotate engine so marks on cam

gear and pinion gear align. Second mark on cam gear must

be at eight o’clock position. In Generator engines, second

mark on pinion gear must be at two o’clock position to align

with mark on circuit breaker drive gear.

5.

Install breather gear and shim, aligning breather gear timing

mark with eight o’clock mark on cam gear. See Picture 16B.

6.

In Generator engines only, install breather screen and

separator (not supplied by S&S) if desired.

7. Use connecting rods to rotate flywheels and insure gears

rotate freely. Apply assembly lube to ends of shafts and

meshing surfaces of gears and remove excess.

8. Apply assembly lube to gear cover bushings.

9. Clean gasket surfaces on engine and gear cover with lacquer

thinner, wipe dry, and apply light film of Hylomar

®

or

preferred sealant to both sides of gasket.

10. Install gasket and cover and tighten screws to 10-12 ft-lbs.

NOTE - Gear cover should slide smoothly over alignment dowels

and must not be forced. Confirm that gasket material does not

overlap oil passages in crankcase and gear cover. See Picture 18.

7

Picture 16A

Picture 16B

CAUTION

Picture 17