Caution – S&S Cycle Big Twin Engines with 3-1/2 and 3-5/8 Bore Crankcases and Special Application (SA) 4 Bore Crankcases User Manual

Page 8

Having to force gear cover indicates alignment problem.

Problem must be identified and corrected before operating

engine. Operating engine with forced gear cover could result

in broken pinion shaft or other engine damage.

11. Rotate flywheels to check for binding. If present, cause of

bind must be determined and corrected. If assembly rotates

freely, pour approximately four ounces of oil into gear

compartment after allowing crankcase sealant to cure per

manufacturer’s instructions.

INSTALL LIFTERS AND LIFTER GUIDES

(All Unassembled)

NOTE - S&S

®

installs HL

2

T (Hydraulic Lifter Limited Travel) Kit in

lifters in assembled big twin engines. HL

2

T Kit is included with

unassembled big twin engines, but not installed. S&S

recommends using kit. If desired, install kit according to

Installation Instructions for S&S Hydraulic Lifter Limited Travel Kit

#5038 before proceeding.

Install big twin lifters and guides as follows:

1. Remove oil pressure sending unit behind rear lifter

guide opening.

2. Identify gaskets for front and rear lifter guides and apply

thin film of Hylomar

®

or preferred sealant to both sides of

each. Gaskets are not interchangeable.

3. Coat lifter guide bores with assembly lube and insert lifters.

Work lifters back and forth in guides, assuring that they

move freely and without binding. Apply assembly lube to

lifter rollers and remove any excess.

4.

Thoroughly clean and dry gasket surfaces of lifter guides and

crankcase. Place rear gasket on crankcase, assuring that oil

hole in gasket aligns with passage in case.

5. Taking care not to dislodge or contaminate gasket, lower

rear guide assembly into place. Fingers can be inserted

through front lifter guide opening to support lifters.

All reference to Harley-Davidson

®

part numbers is for

identification purposes only. We in no way are implying that

any of S&S

®

Cycle’s products are original equipment or that they

are equivalent to the corresponding Harley-Davidson

®

part

number shown.

6. Insert

Harley-Davidson

®

alignment tool H-D

®

#33443 or

similar tool from other source in lifter guide screw hole by oil

passage. See Picture 19. Install and tighten guide screws in

three remaining holes. Remove tool, install fourth screw, and

tighten all to 10-12 ft-lbs.

7. Repeat procedure for front lifter-guide assembly.

Assembly lube will usually hold lifters in guide during

installation. If resistance encountered, check to see if lifter

has become dislodged.

8. Apply thread sealant to threads of oil pressure switch

and install.

Install shovelhead lifters and guides according to

manufacturer’s instructions.

CRANKCASE VENT (Big Twin Engines)

Before further assembly, it must be decided whether engine is to

vent crankcase pressure out crankcase, cylinder heads, or both.

S&S big twin engines are compatible with both, and S&S

recommends dual venting whenever possible, especially with

four inch bore engines. If different gear cover is installed by

customer, for crankcase vent or dual venting it must be of Harley-

Davidson

®

‘92-older and used with correct gasket. ‘93-up lower

rocker covers and correct gaskets must be used for cylinder head

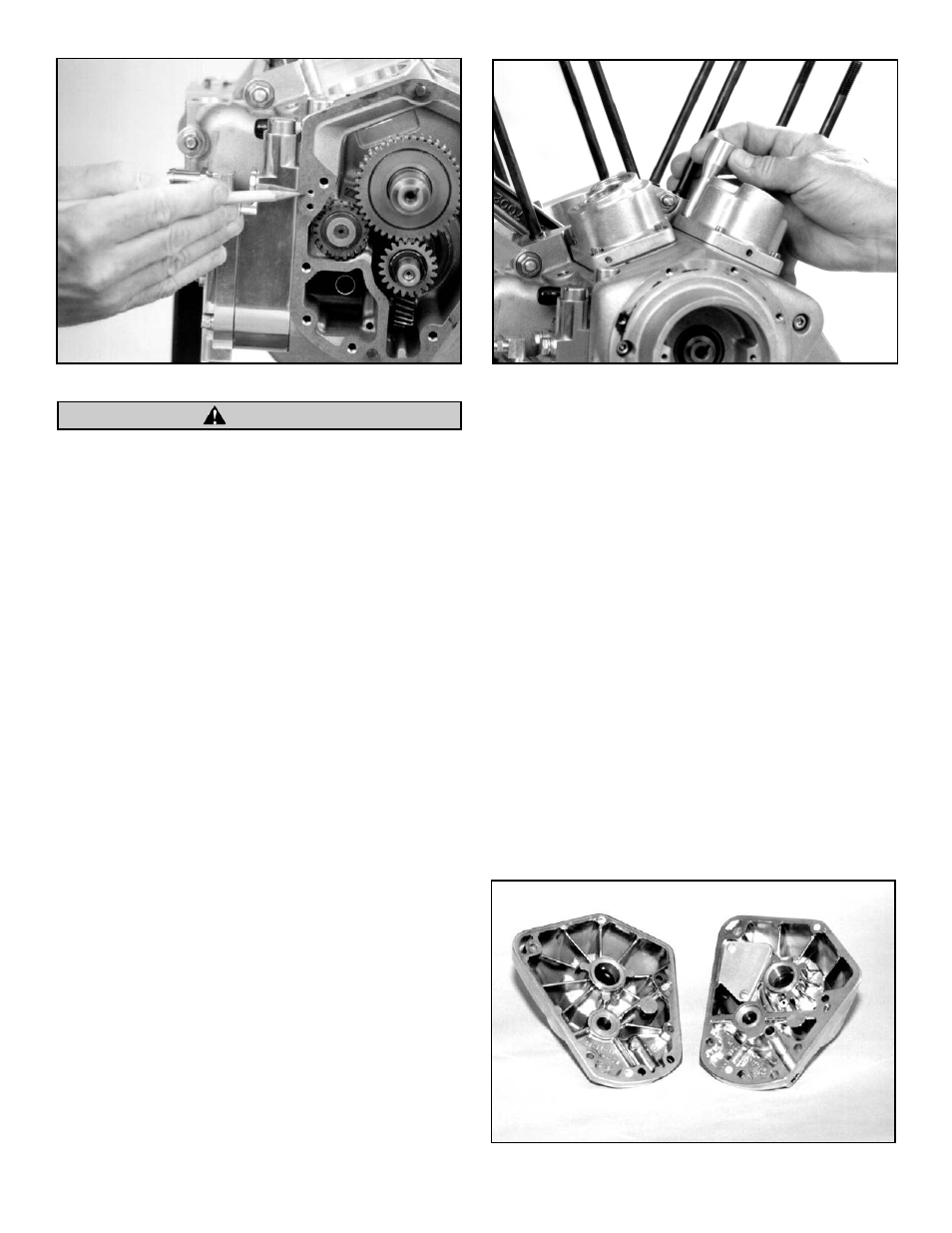

venting and dual vent arrangement. See Pictures 20 & 21.

Center sections with umbrella valves must also be used.

8

Picture 18

Picture 19

CAUTION

Picture 20

1993-Later

1992-Earlier