S&S Cycle TÜV Approved Super E Carburetor Kits User Manual

Page 15

15

WARNING

Compressed air and particles dislodged by compressed air are potentially harmful to eyes and body. Wear protective goggles when

using compressed air and always direct air stream away from yourself and others nearby.

8. Improper diagnosis of rich or lean mixture condition. If engine backfires in carburetor, mixture is usually lean and engine must be

reprimed. If there is no response after three kicks or if engine pops in exhaust pipes, mixture is probably too rich. Leave switch on and

slowly open throttle 1⁄4 turn with each successive kick until engine fires.

9. If engine was running properly before installation of carburetor, no other changes were made and carburetor settings were confirmed

as instructed previously, hard starting is likely caused by incorrect intermediate jet or starting routine. Remain calm and patient while

attempting to start motorcycle, and experiment with different starting procedures (throttle and enrichener position, number of squirts

from accelerator pump, etc.), especially with kickstart motorcycle. Carburetor tuning and ignition tuning and maintenance are critical

for kick start motorcycles.

NOTES:

If severe flooding is suspected, turn ignition off, slowly roll throttle to wide open position, and kick 6-8 times to clear engine. Then close throttle

•

to approximately 1⁄8 turn, turn ignition on and kick until engine starts.

If insufficient fuel is suspected, remove air cleaner cover and confirm accelerator pump operation by snapping throttle open from closed position.

•

Fuel should exit accelerator pump nozzle directly behind main discharge tube in carburetor bore.

No more than 2-3 squirts from accelerator pump should be required to start motorcycle with temperature 60°F or above. This may also be caused

•

by incorrect idle mixture adjustment or a manifold leak. Refer to following sections for additional information on tuning.

2. Adjusting Carburetor

The carburetor comes preset from S&S®. It is illegal to adjust the carburetor to settings other than those provided in the documentation included

with the engine. In the case maintenance is needed the idle emissions and idle speed may be reset to the specification in the documentation by the

following procedure.

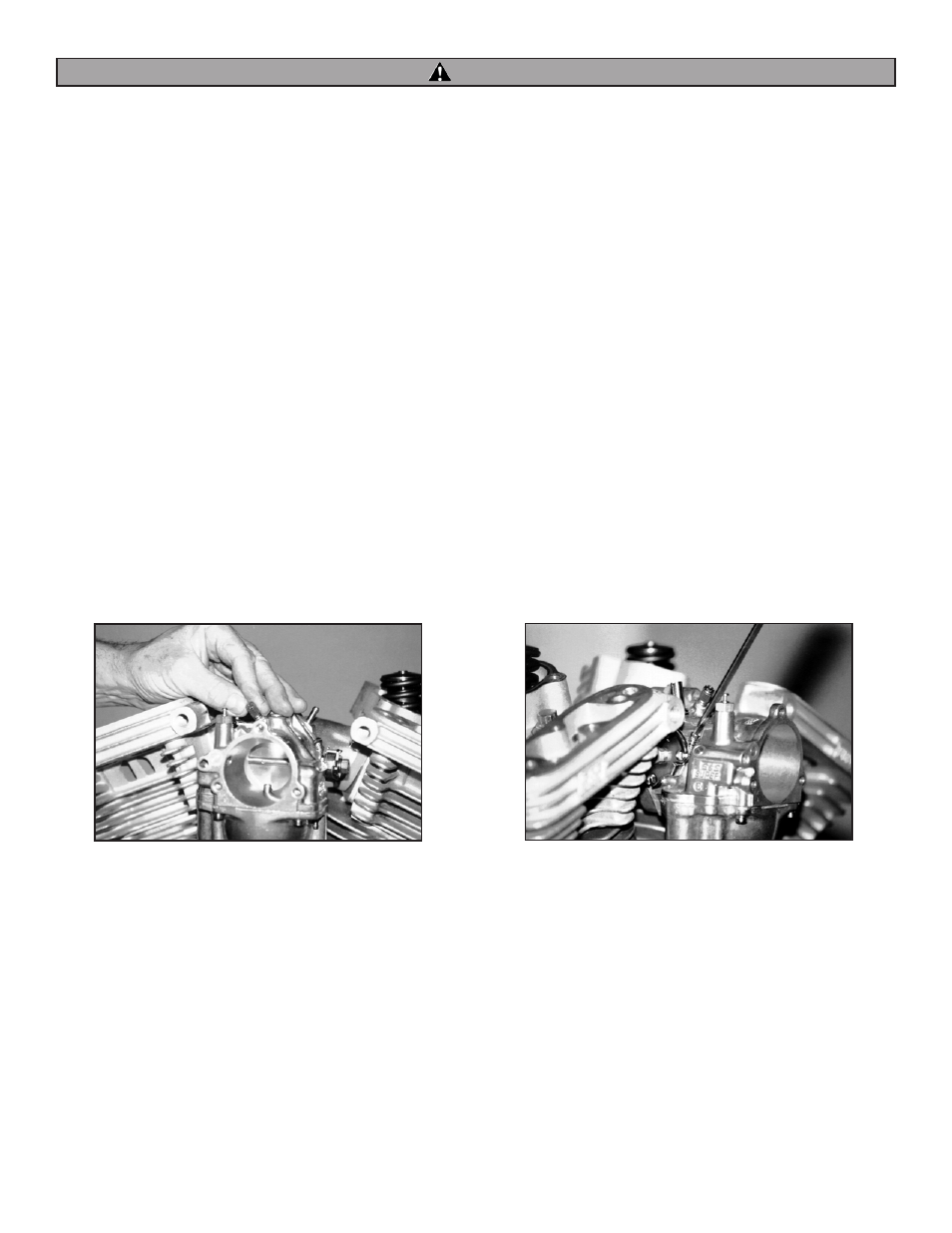

A. Adjusting Idle Circuit for idle emission – The idle mixture screw regulates air/fuel mixture at idle speeds and has been angled out for greater

accessibility. See Picture 30. Engine rpm adjustment screw is located on boss on rear side of carburetor body. See Picture 31. During

assembly S&S adjusts both screws to settings that should work for your application.

1. Start engine and allow it to fully warn up.

2. Adjust idle speed by turning rpm adjustment screw.

3. Adjust idle emissions by turning idle mixture screw.

4. Verify idle speed has not changed.

Picture 30

Picture 31