Making fitting connections – RKI Instruments Digester Gas Monitor User Manual

Page 34

28 • Making Fitting Connections

Digester Gas Monitor Operator’s Manual

6.

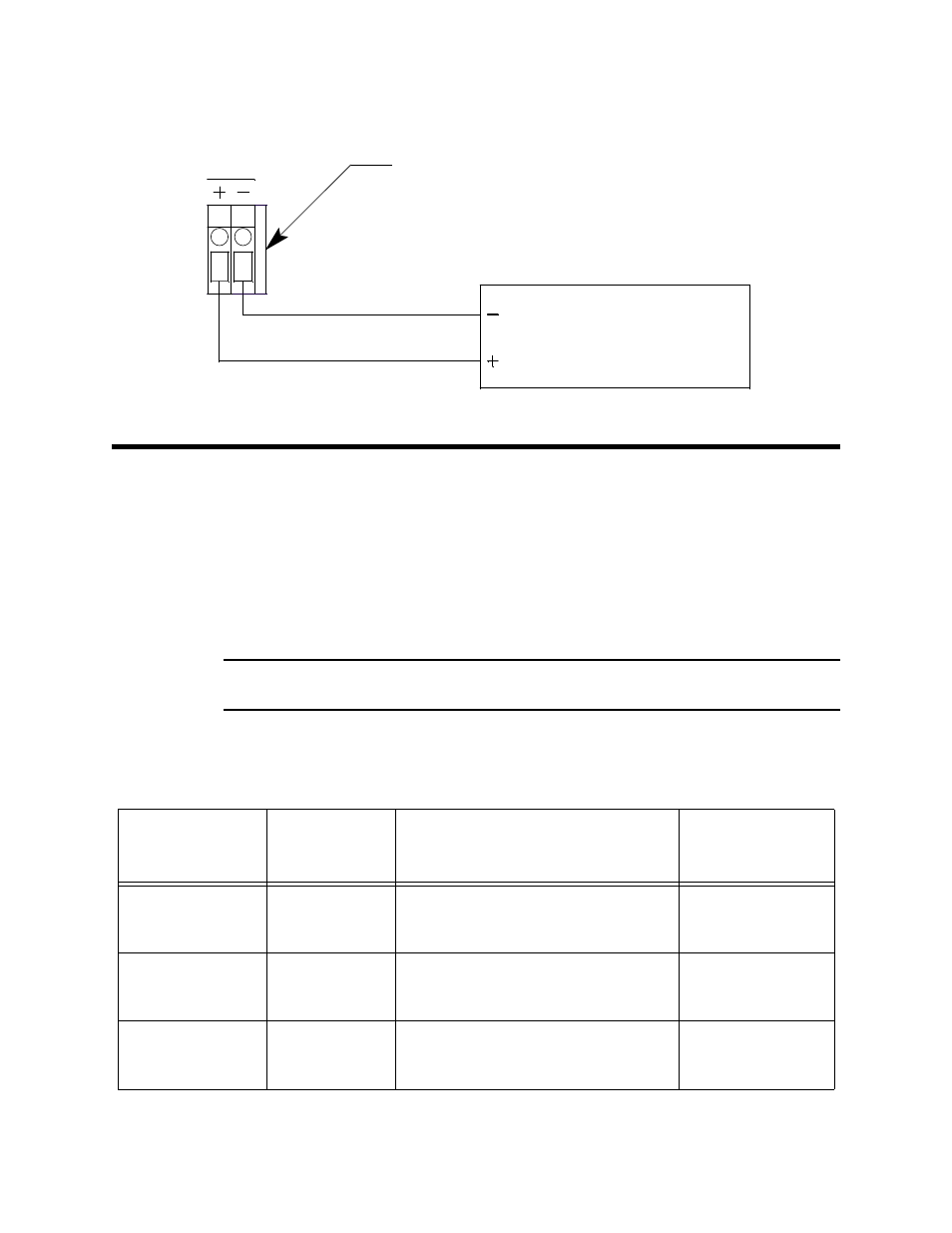

Connect the leads from the recording device to the recorder output terminals of the

selected active channels as shown in Figure 16 below.

Figure 16: Recorder Output Wiring

Making Fitting Connections

Compression Fitting Connections

The fresh air inlet, dryer exhaust, digester sample inlet, and compressed air inlet fittings

are all compression fittings with ferrules that accept rigid metal or rigid plastic tubing. The

tube nuts are loosely screwed on and are not tightened completely. Do not tighten the tube

nut until a rigid tube is inserted.

The compression fittings accept 1/4 inch OD rigid metal or rigid plastic tubing. Stainless

steel, Teflon, or polypropylene tubing is recommended.

NOTE: Rigid metal must be used to connect to the compressed air inlet compression

fitting.

The maximum lengths of tubing that can be connected to each compression fitting, the

recommended size, and the recommended material are outlined in the table below.

Table 4: Compression Fitting Maximum Tubing Lengths

Fitting

Maximum

Tubing Length

(ft.)

Recommended Tubing Size

Recommended

Tubing Material

Fresh Air Inlet

100

•

1/4 inch OD x 3/16 inch ID plastic

•

1/4 inch OD x 0.035 inch wall metal

Stainless steel,

Teflon, or

polypropylene

Digester Sample

Inlet

100

•

1/4 inch OD x 3/16 inch ID plastic

•

1/4 inch OD x 0.035 inch wall metal

Stainless steel,

Teflon, or

polypropylene

Dryer Exhaust*

50

•

1/4 inch OD x 3/16 inch ID plastic

•

1/4 inch OD x 0.035 inch wall metal

Stainless steel,

Teflon, or

polypropylene

Recorder Output Terminals From a

Detector/Transmitter Terminal Strip,

Typical of 4

4-20 mA

OUTPUT

4 - 20 mA Input

Recording Device

500 Ohms Impedance

Maximum