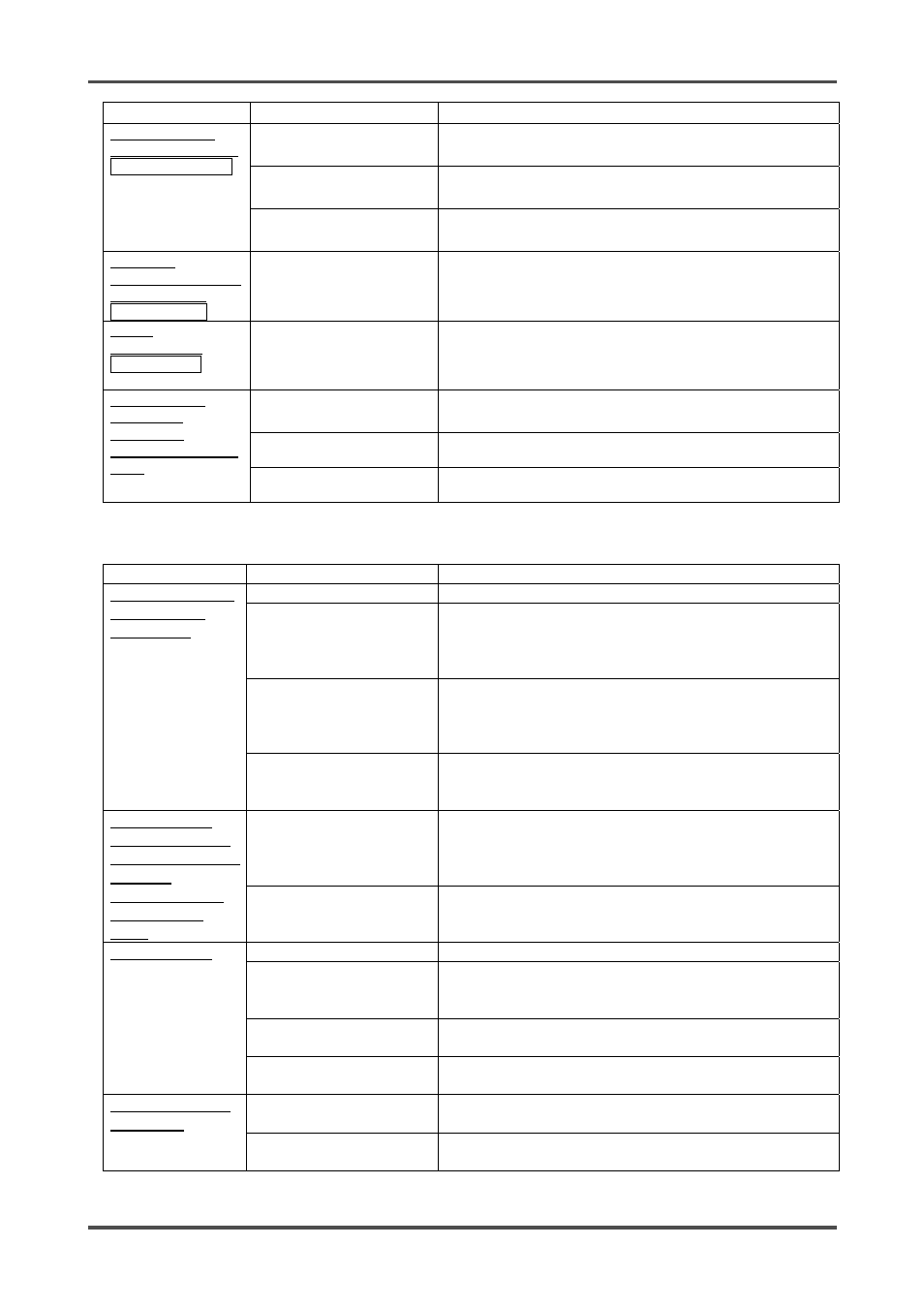

Abnormalities of readings – RKI Instruments GX-8000(PT0-098) User Manual

Page 47

8 Troubleshooting

- 47 -

GX-8000

Symptoms Causes

Actions

Water or oil, etc. was

drawn in.

Check the gas sampling hose for any damage or mark of

drawn water or oil, etc.

The gas sampling hose

is clogged.

Check the gas sampling hose for connections, clogging,

twisting, etc.

A low flow rate

alarm is displayed.

FAIL LOW FLOW

The pump has

deteriorated.

Request RIKEN KEIKI to replace the pump.

Fresh air

adjustment cannot

be performed.

FAIL AIR CAL

Fresh air is not supplied

around the gas monitor.

Supply fresh air.

Clock

abnormalities

FAIL CLOCK

Abnormalities of the

internal clock

Make a setting of Date/Time.

If such a symptom is observed repeatedly, the built-in

clock is seemingly malfunctioning. Thus, it must be

replaced. Please contact RIKEN KEIKI.

The charger is not

connected properly.

Connect the AC powered charger to the wall electric

outlet and jack properly.

A recharging circuit

abnormality occurred.

Request RIKEN KEIKI for repair.

The batteries

cannot be

recharged.

(Li-ion battery unit

only)

The batteries have been

fully charged.

When fully recharged batteries are recharged again, the

recharging indicator lamp does not go on.

Symptoms Causes

Actions

Drifting of sensor output

Perform the zero adjustment (fresh air adjustment).

Presence of interference

gas

Disturbances by interference gases, such as solvents,

cannot be eliminated completely. For information on

actions, such as removal filter, please contact RIKEN

KEIKI.

Slow leak

A very small amount of the gas to be detected may be

leaking (slow leak). Because ignoring it may cause

dangers, take a remedial measure, i.e., taking actions

the same as those for the gas alarm.

The reading rises

(drops) and it

remains so.

Environmental changes

Perform the zero adjustment (fresh air adjustment).

In particular, the galvanic cell type is affected by the air

pressure.

Presence of interference

gas

Disturbances by interference gases, such as solvents,

cannot be eliminated completely. For information on

actions, such as removal filter, please contact RIKEN

KEIKI.

A gas alarm is

triggered despite

of no gas leak and

no other

abnormalities at

the detection

point.

Disturbance by noise

Turn off and restart the gas monitor.

If such a symptom is observed frequently, take

appropriate measures to eliminate the noise.

Clogged dust filter

Replace the dust filter.

Bended or clogged

suction tube or exhaust

tube

Fix the defective parts.

Condensation is formed

inside the suction tube.

Fix the defective parts.

Slow response

Deteriorated sensor

sensitivity

Replace the sensor unit with a new one.

Improper calibration gas

concentration

Use the proper calibration gas.

Span adjustment

impossible

Deteriorated sensor

sensitivity

Replace the sensor unit with a new one.