Repair, 1 checklist for troubleshooting – Retsch DM 400 User Manual

Page 52

Repair

52

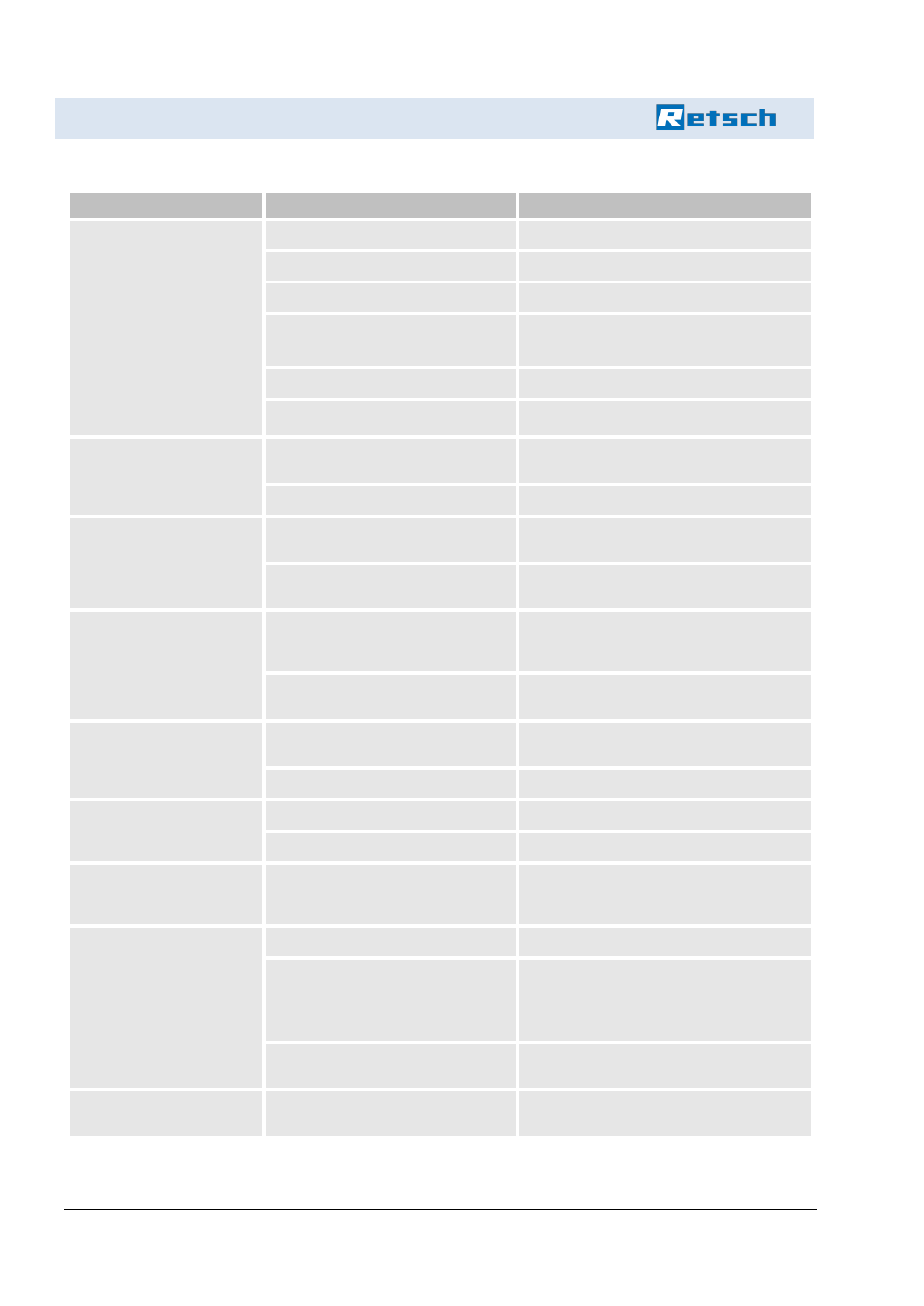

8.1 Checklist for troubleshooting

Malfunction

Possible cause

Rectification of fault

Mill does not start

No mains connection

Plug in

Mains switch is off

Switch the mains switch on

Grinding chamber safety switch open

Correctly connect the grinding chamber

Sample material container safety switch

open

Correctly insert the sample material container

Thermal circuit breaker has triggered

Wait until the device has cooled down

Fuse in the control circuit has triggered

Have the fuse replaced by qualified specialists.

Discs do not rotate

Gap width set to 0

Adjust the gap width! See chapter

“Working with

the disc mill

”

Sample is blocking the disc

Open grinding chamber and remove the sample

Mill stands still during operation

Overload! Switch off by motor circuit

breaker switch (main switch)

Allow the mill to cool. Remove sample material,

reduce feed of sample material

Grinding chamber overfilled. Too large /

hard sample material has become stuck

Open the grinding chamber and empty

Mill produces poor grinding

result

Grinding discs are worn

Change the direction of rotation or replace grind-

ing discs. See chapter

“Reverse operation” or

chapter

“Replacing the grinding discs (5 + 6)“

Grinding discs are not installed in parallel

Remove grinding discs, clean the support and

reinsert (see

chapter “Working with the disc mill” )

Sample materials escapes

Grinding chamber seals and sample

material container seals dirty or faulty

Clean or replace seals

Collecting container overfilled (max. 2l)

Remove container and clean the inside

Error message sample material

container

Sample material container not recognised

Slide container in centrally

Soiling of the container guide

Cleaning

No release of the sample

material container after STOP

Release mechanism on sample material

container faulty

Release by emergency actuation inside the

device; see

chapter “Protection against restart-

ing

”. Contact Retsch!

Automatic gap adjustment not

possible

Control panel is faulty

Replace the control panel

Gap adjustment is faulty

Contact Retsch

Temporary problem solution using the set screw

(7) on the bottom right-hand side at the front!

Adjust the precise gap width manually!

Discs have got stuck

With the help of the set screw (7), loosen! Rea-

lign the zero point!

Error message

Gap width, grinding chamber, sample

material container

Actuate the STOP button