Servicing – Retsch DM 400 User Manual

Page 43

Servicing

43

CAUTION!

- Risk of crushing when changing the grinding discs.

- When changing grinding discs, secure them to

prevent them falling down.

CAUTION!

Before inserting the new discs, clean the support and the

back of the discs thoroughly. This is in particular very

important when using the ZrO

2

discs and also with

TC+CO discs, so that the discs are positioned without

tension and parallel to each other.

It is also important when tightening the screws that the

tightening torque is not too great (see table) and is the

same for both screws.

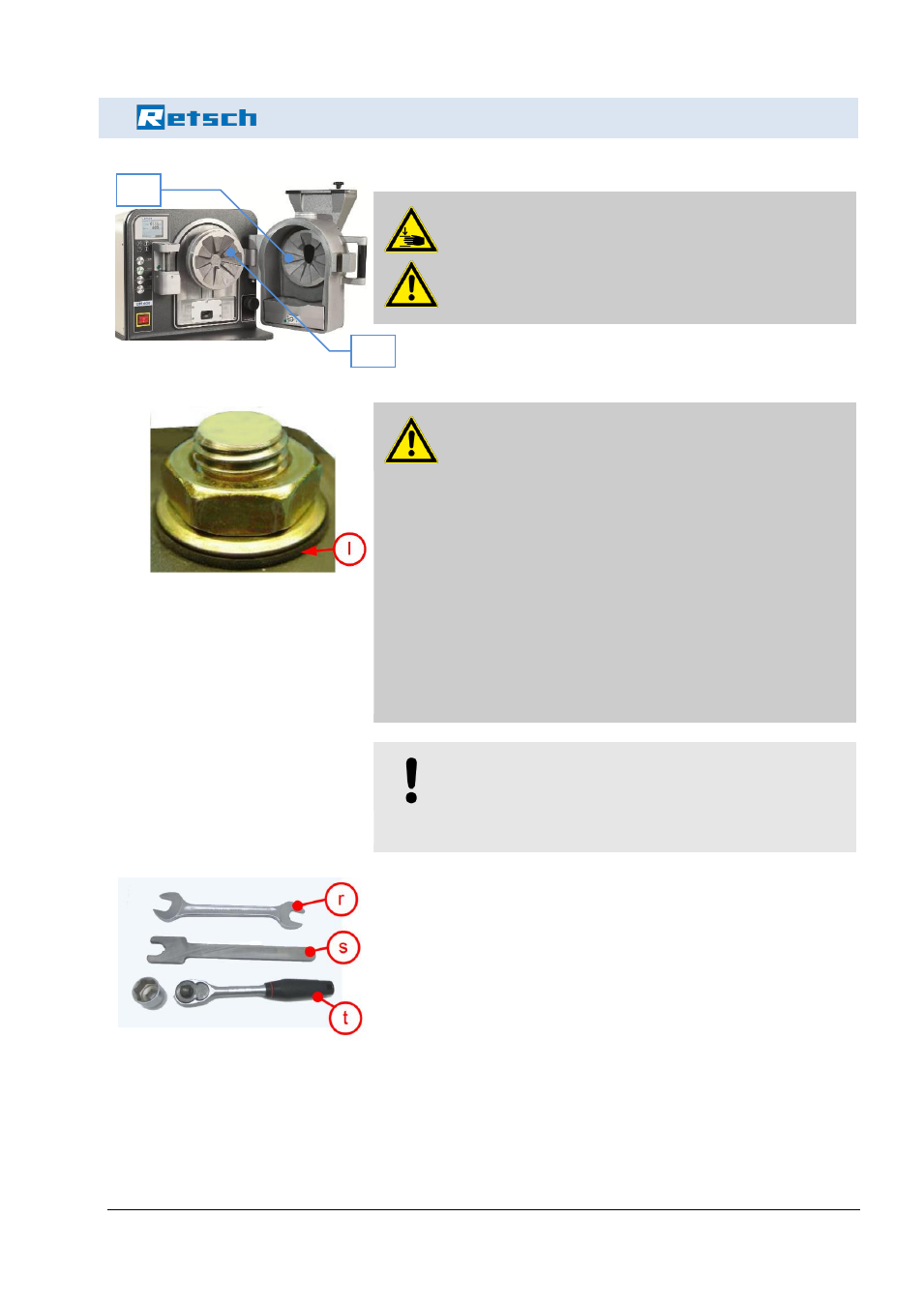

Rubber washers (I) which are placed under the steel

washers are used with ZrO

2

grinding discs. The nuts are

then tightened until the rubber washer slightly squeezes

out beneath the steel washer. This ensures a tightening

torque of approx. 20Nm.

NOTICE!

When replacing grinding discs, hold them securely and

do not allow them to fall. In the case of zirconium oxide

discs, this can lead to breakage or chipping.

Tools required:

M20 spanner wrench (r)

Motor shaft retainer (s)

30 mm ratchet wrench (t)

6

5