Installation, 3 positioning – Retsch DM 400 User Manual

Page 24

Installation

24

4.3 Positioning

DANGER!

Do not walk under the transport pallet during transport.

To position the disc mill you will need a crane or other suitable means

of transport as well as 2 carrying straps (not included with delivery)

with a minimum length of 40cm and loadbearing capacity of 500 kg.

CAUTION!

Weight of the disc mill is approx. 260 kg with grinding

discs (WC) and transport pallet!

NOTICE!

The disc mill must be placed on an even, stable surface.

It can be screwed to this or to a base plate.

1. The disc mill is screwed to the transport pallet from underneath

using 3 screws. Loosen screws using a spanner wrench (17

mm).

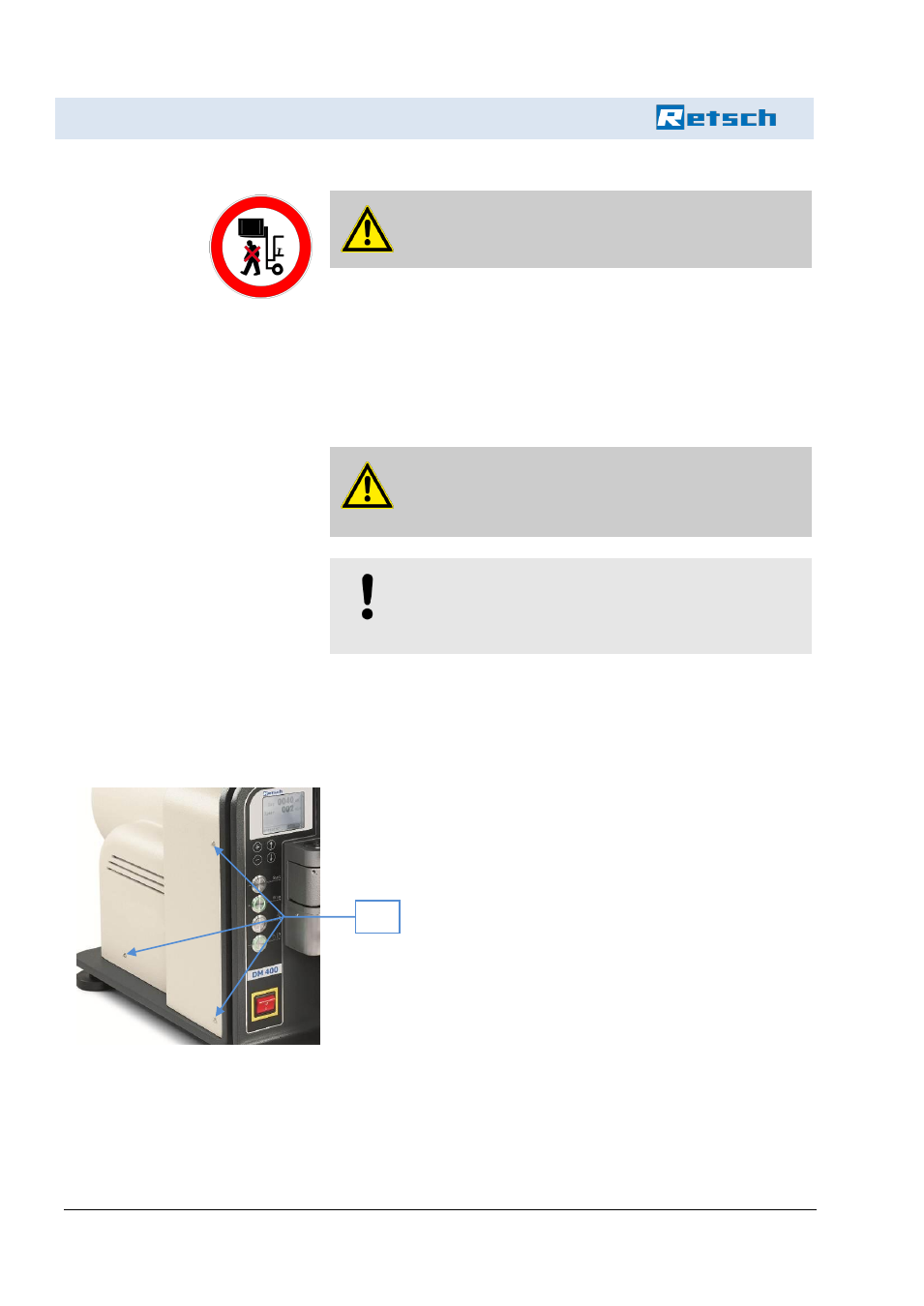

2. Open the housing cover (14) by unscrewing the quick acting

screws on either side.

14S

- BB 50 (41 pages)

- BB 100 (24 pages)

- BB 200 (24 pages)

- BB 300 (24 pages)

- Cryomill (68 pages)

- CryoMill Autofill 50l (28 pages)

- DM 200 (20 pages)

- Emax (67 pages)

- GM 200 (44 pages)

- GM 300 (44 pages)

- MM 200 (32 pages)

- MM 400 (32 pages)

- PM 100 (44 pages)

- PM 400 (36 pages)

- PM GrindControl (48 pages)

- RM 200 (36 pages)

- RS 200 (32 pages)

- SK 100 (24 pages)

- SM 100 (48 pages)

- SM 200 (48 pages)

- SM 300 (44 pages)

- Cyclone - SM 300 (20 pages)

- SR 200 (24 pages)

- SR 300 (24 pages)

- TWISTER (44 pages)

- ZM 200 (32 pages)

- AS 200 jet - Automatic Vacuum Regulation (6 pages)

- AS 200 control - natural frequency (32 pages)

- AS 200 (36 pages)

- AS 200 jet (56 pages)

- AS 200 jet (48 pages)

- AS 200 tap 30.025.0001 (28 pages)

- AS 200 tap 30.025.1001 (28 pages)

- AS 300 (32 pages)

- AS 400 (32 pages)

- AS 400 (28 pages)

- AS 450 basic (40 pages)

- AS 450 basic (44 pages)

- AS 450 control (52 pages)

- DR 100 (40 pages)

- DR 100 (28 pages)

- PP 25 (32 pages)

- PP 40 (28 pages)

- PT 100 (36 pages)